Yellow building coating with high near-infrared reflection rate and preparation method thereof

A technology of infrared reflection and architectural coatings, applied in the field of coatings, can solve the problems of low tinting strength, unreachable near-infrared reflectance, large dosage, etc., and achieve the effect of reducing building energy consumption and reducing environmental and personal hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

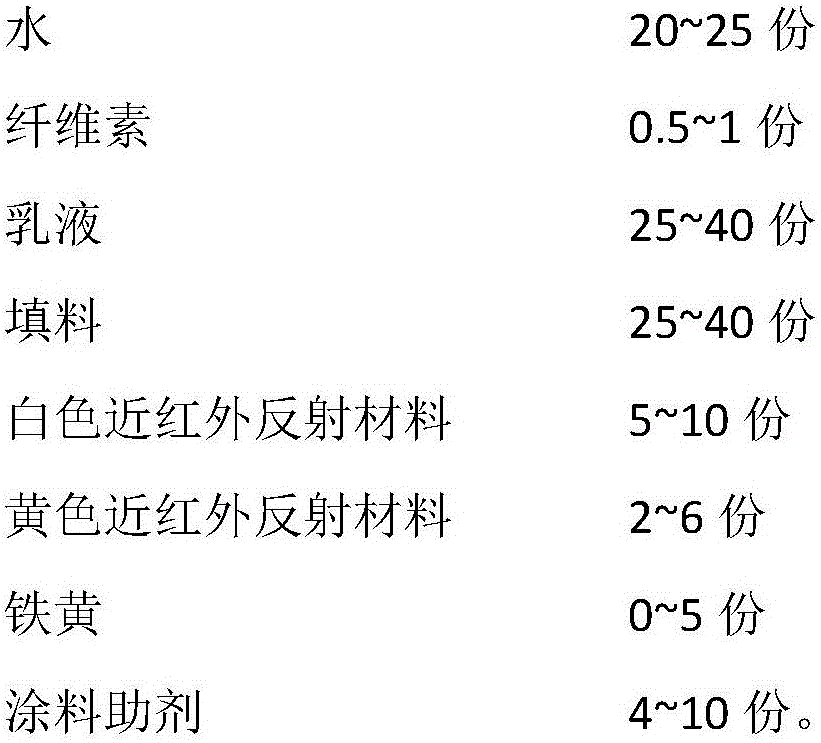

[0026] Main composition parts by weight are as follows:

[0027]

[0028] The preparation method is as follows:

[0029] Step 1. Add 20 parts of water to the paint mixing tank, adjust the high-speed stirring speed to 400rpm, then add 0.5 parts of cellulose, and after the dispersion is even, add 3 parts of other additives successively, and disperse evenly again;

[0030] Step 2. Adjust the stirring speed to 1000 rpm, add 25 parts of filler to the slurry obtained in step 1, and adjust the speed to 2400 rpm to disperse after the filler is wetted until the fineness of the dispersed slurry is less than 50 μm;

[0031] Step 3. Adjust the stirring speed to 1000rpm. Add 6 parts of white near-infrared reflective material IR-1000, 4 parts of yellow near-infrared reflective material, and 5 parts of iron yellow to the slurry obtained in step 2. After the materials are wetted, adjust the speed to Disperse at 2500rpm until the fineness of the dispersed slurry is less than 50μm;

[0032...

Embodiment 2

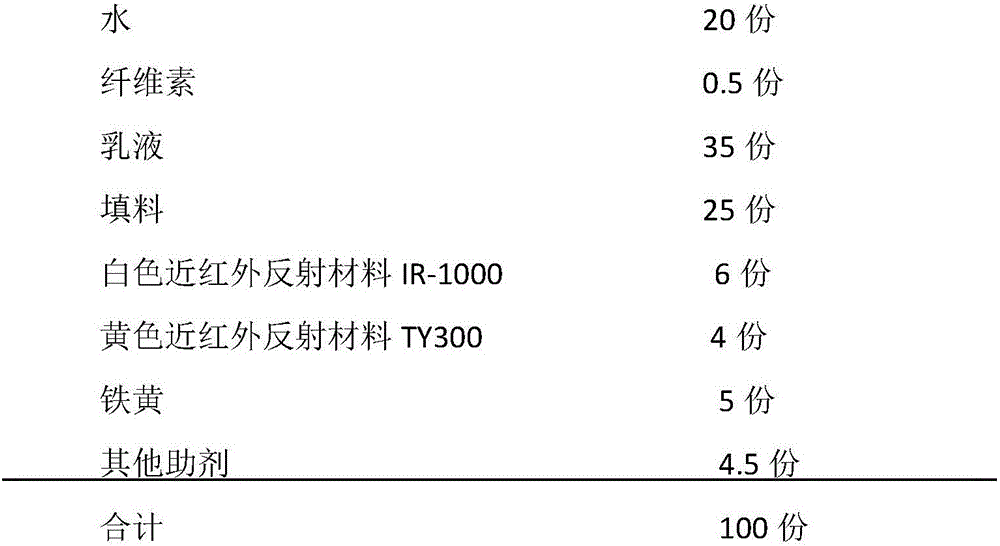

[0034] Main composition parts by weight are as follows:

[0035]

[0036]

[0037] The preparation method is the same as in Example 1.

Embodiment 3

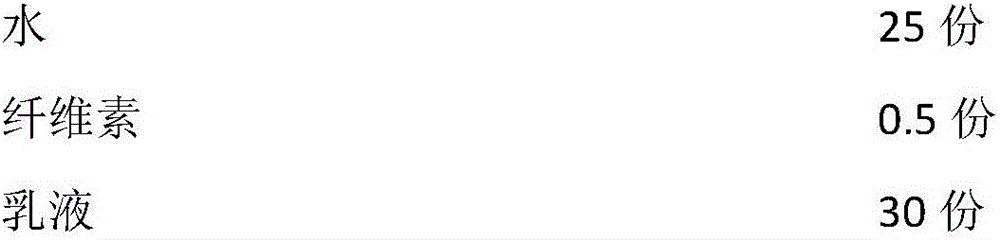

[0039] Main composition parts by weight are as follows:

[0040]

[0041] The preparation method is the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap