A crawler steel pipe pile with reduced negative friction resistance and its construction method

A technology of negative friction resistance and steel pipe piles, which is applied in the field of building foundation engineering, can solve the problems of weakening pile body bearing capacity, reduced pile body bearing capacity, and uneven settlement of superstructures, so as to increase positive friction resistance, The effect of reducing negative frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

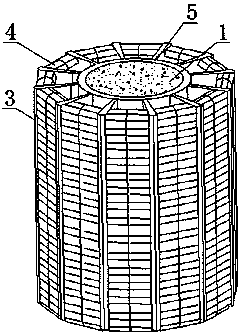

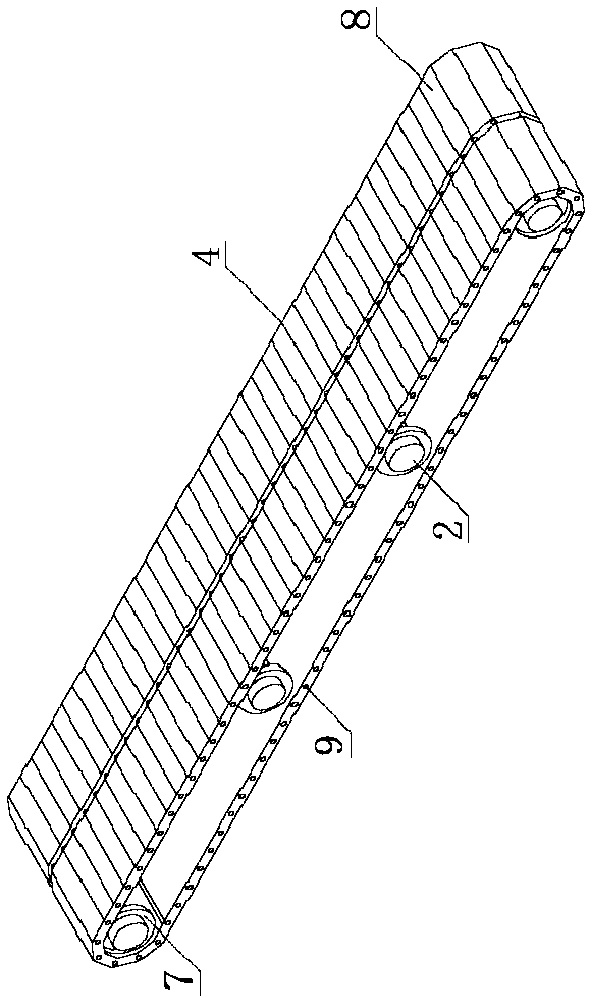

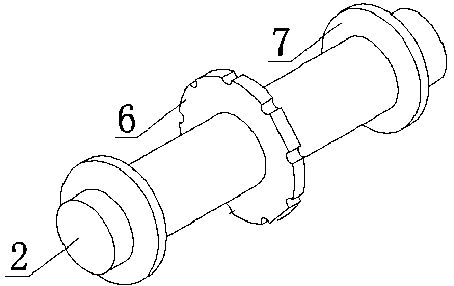

[0016] Working principle of the present invention: (1) Negative frictional resistance rotation principle: In collapsible loess and soft soil areas, soil settlement will generate downward sliding friction on the pile body, driving the steel track and one-way rotating gear to rotate When the gear shaft rotates, the sliding friction force generated by the soil settlement on the pile body is converted into the power to make the crawler belt and the one-way rotating gear rotate around the gear shaft, so as to reduce or even eliminate the negative friction resistance between the pile and soil. (2) Locking principle of positive friction resistance: when bearing the load of the upper structure, the settlement of the pile body will drive the outer steel crawler to move upward. At this time, the gear is in a non-rotating state, and the friction generated between the soil and the steel crawler It is transmitted to the pile body through the T-shaped steel beam, so that there is positive fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com