A ring shear test and soil sample preparation device suitable for vertical shear planes

A technology for preparing devices and shear surfaces, which is applied in the preparation of test samples, testing material strength by applying stable shear force, and measuring devices. It can solve the problem of small thickness of shear surfaces, different shear displacements, and difficult simulation Actual rock and soil mechanical properties and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

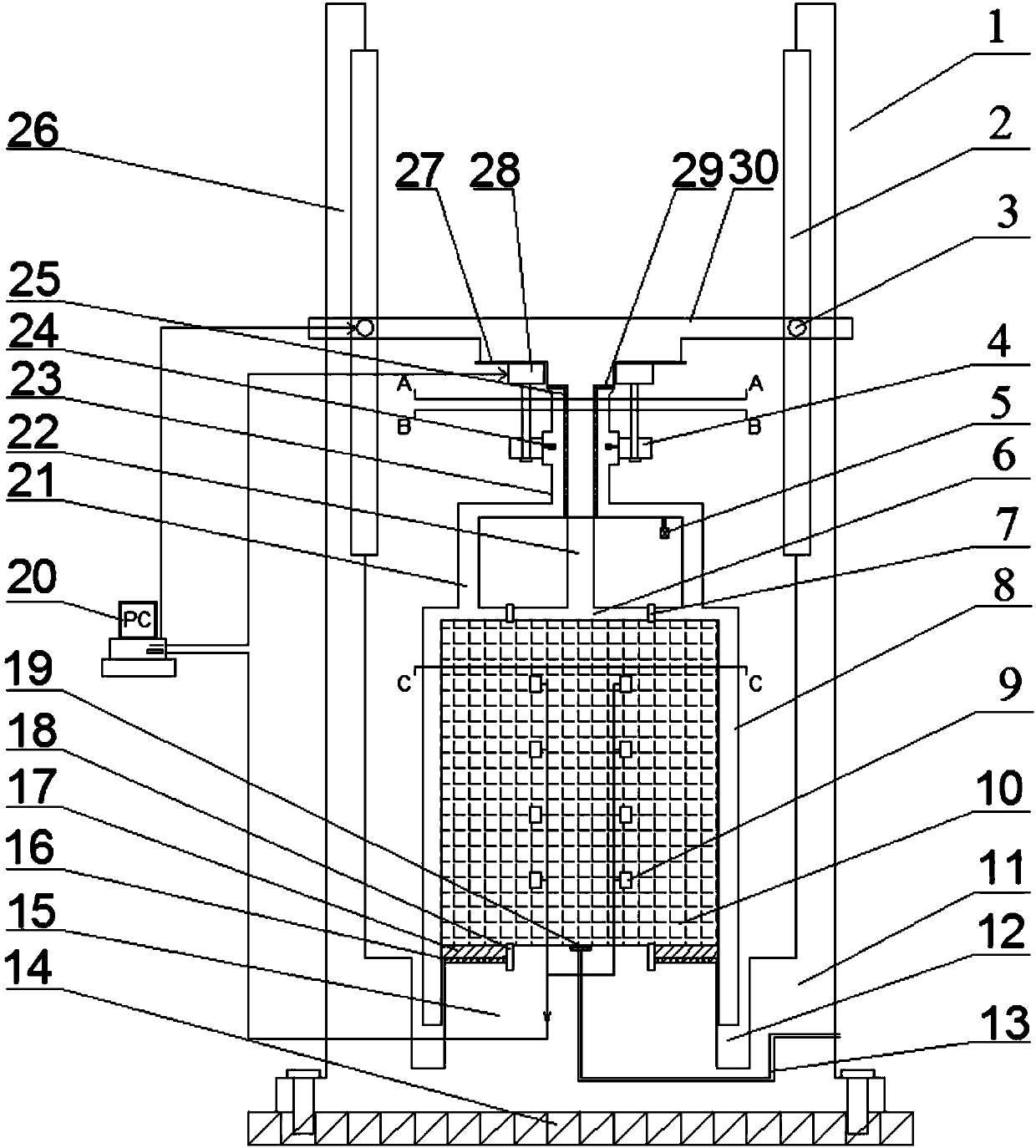

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

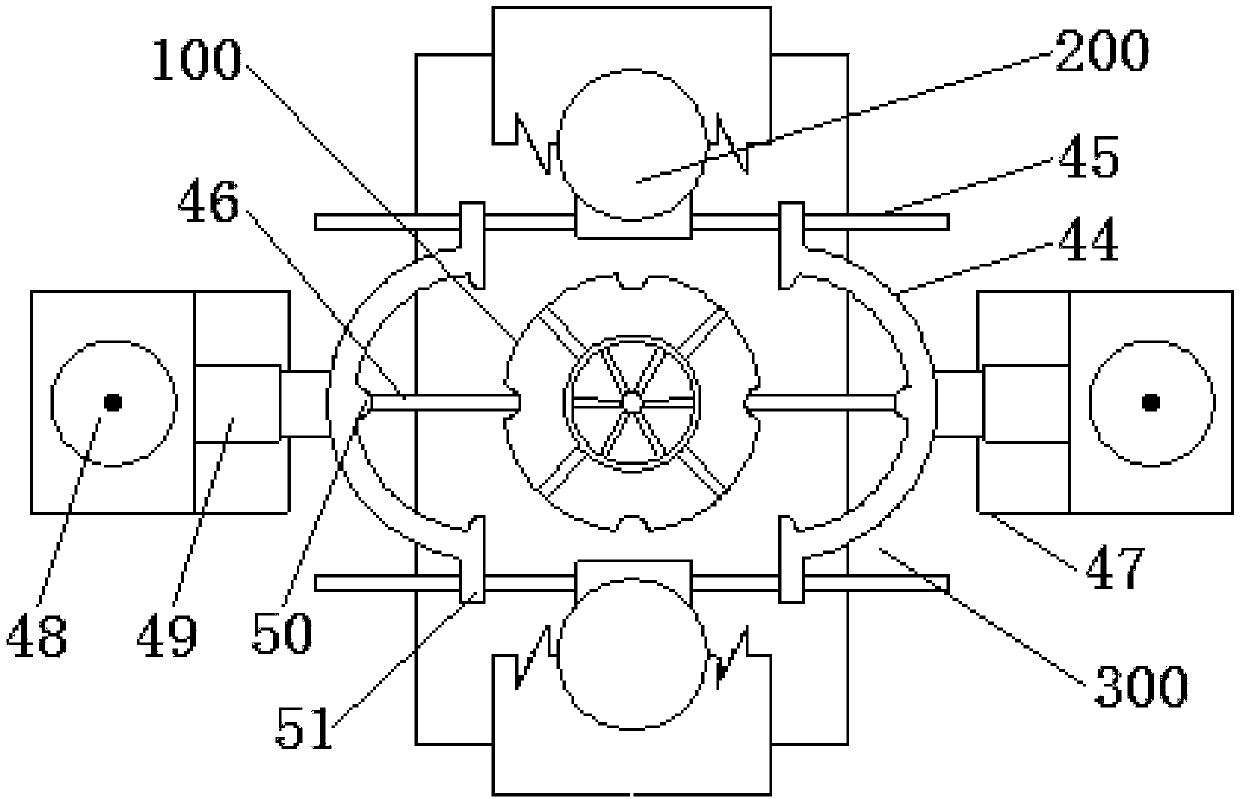

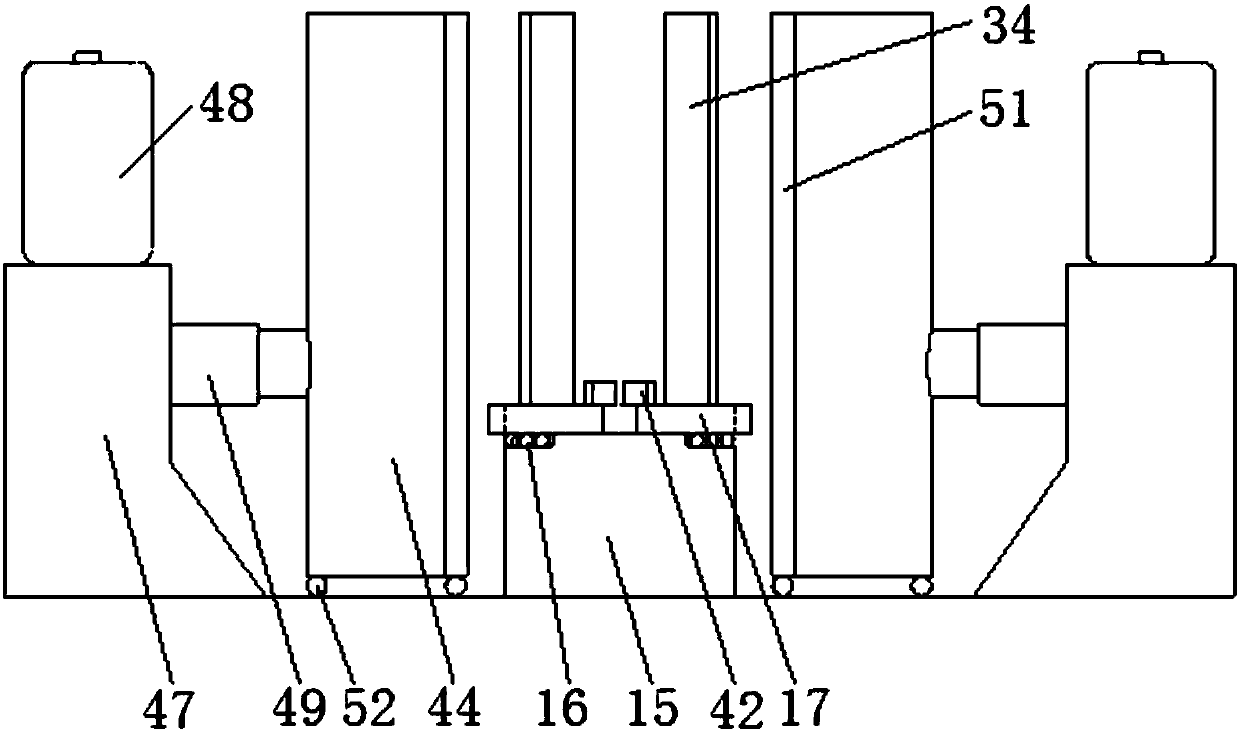

[0042] The ring shear test and soil sample preparation device suitable for vertical shear planes provided by the present invention have a structure such as figure 1 As shown, it includes a shear box 100, a lifting system 200, a power rotation system, a soil sample preparation system 300, a monitoring control system and a frame 1;

[0043] see image 3 , the frame 1 supports the entire test structure, including a base 11 and two columns 26 fixed on both sides of the base 11, a drainage groove 19 is provided in the middle of the base 11, and the surface of the notch of the drainage groove 19 is covered with a layer of felt cloth 41. A water filter board is laid inside, and the bottom of the groove is connected with the drain pipe 13, which is used to control the drain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com