Electric connector and connector assembly

A connector assembly and electrical connector technology, which is applied to the parts, connections, electrical components and other directions of the connecting device, can solve the problems of complex assembly process of electrical connectors, and achieve the effect of avoiding complex process problems and large plugging force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

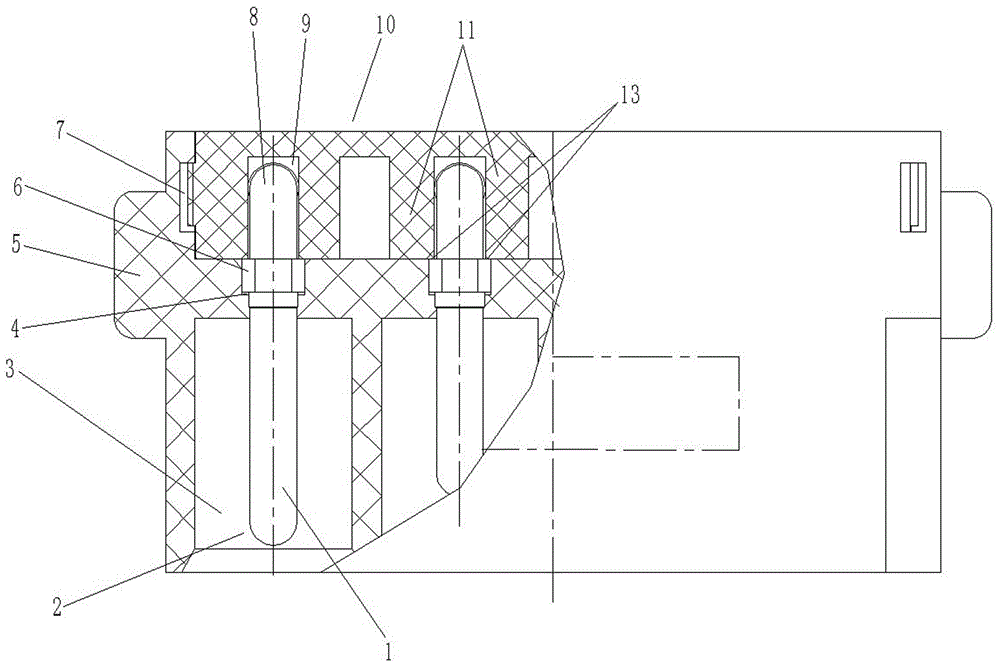

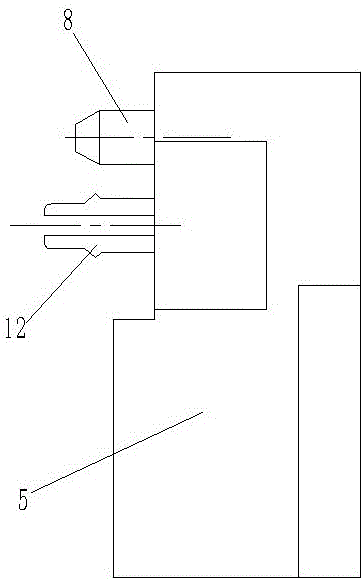

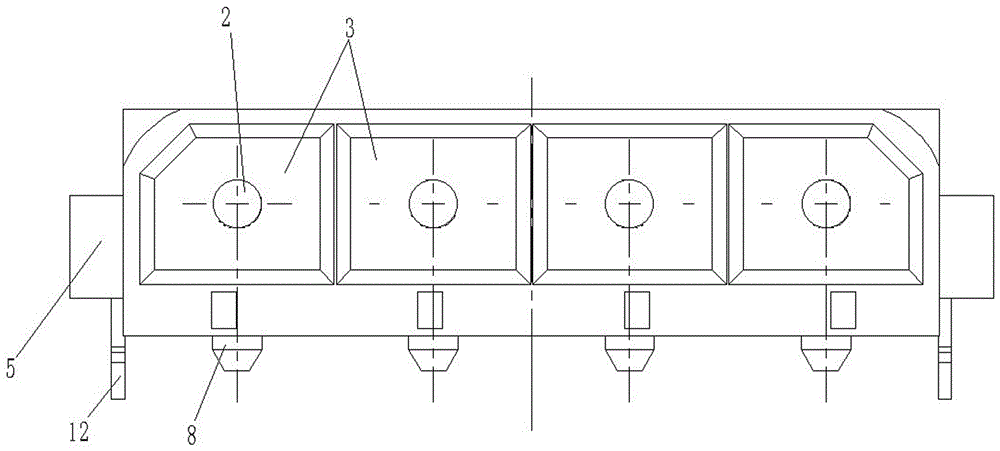

[0031] An example of a connector component is Figure 1~13 Shown: including a plug connector 31 and a socket connector, the plug connector and the socket connector in this embodiment are AC connectors, the socket connector includes a socket insulator 5, a contact pressure plate 10 and four spaced apart along the up and down direction The socket contact piece 2, the socket contact piece 2 is a pin, and the socket contact piece includes a plug-in section 1 whose front end is a plug-in end and a right-bending bending section 8 arranged at the end of the plug-in section, and two adjacent socket contacts The length of the plug-in section 1 of the socket is different. The plug-in section 1 and the bending section 8 form an L-shaped structure. The bending section 8 is used to weld and connect with the printed board. It is an elliptical boss, and the flat rear end face of the positioning constitutes the stop surface of the contact piece. The socket insulator is provided with guide gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com