Lifting handle assembly, method of manufacturing same, method of fetching and placing same, lifting handle assembly carrier carrying same, and lifting handle assembling unit

A technology of assemblies and components, applied in the direction of connecting components, thin plate connections, mechanical equipment, etc., can solve problems such as difficult access, complex production of handle components, and inability to apply various objects, etc., to achieve easy manufacturing and easy access Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] In order to fully understand the purpose, features and effects of the present invention, now through the following specific embodiments, and cooperate with the accompanying drawings, the present invention is described in detail, as follows:

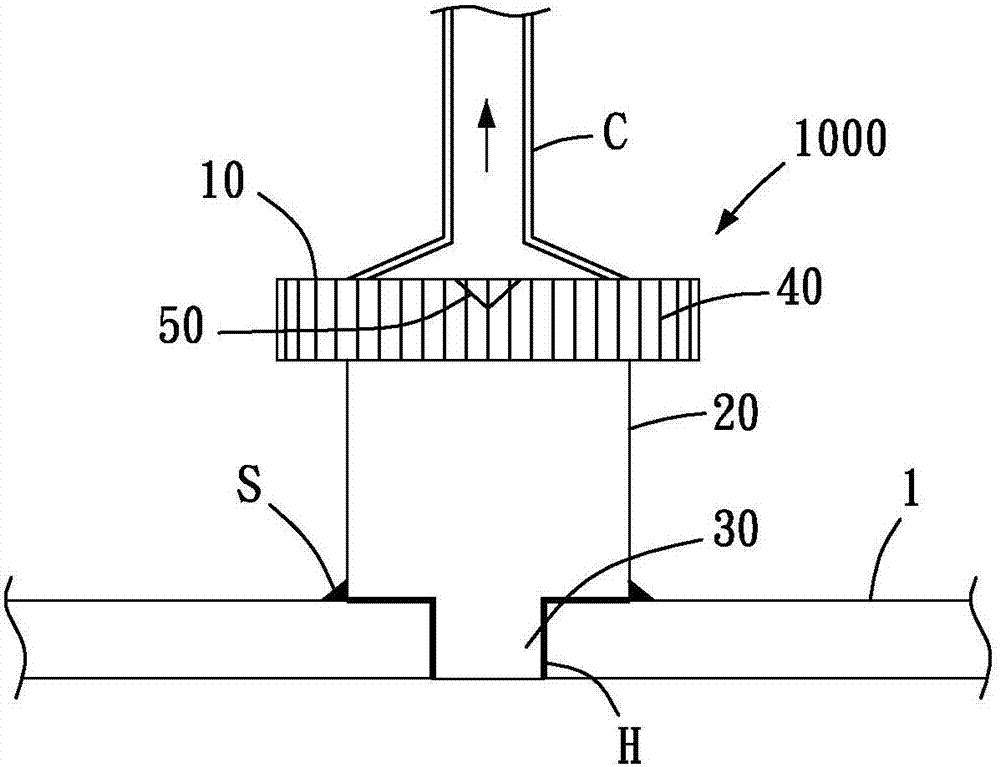

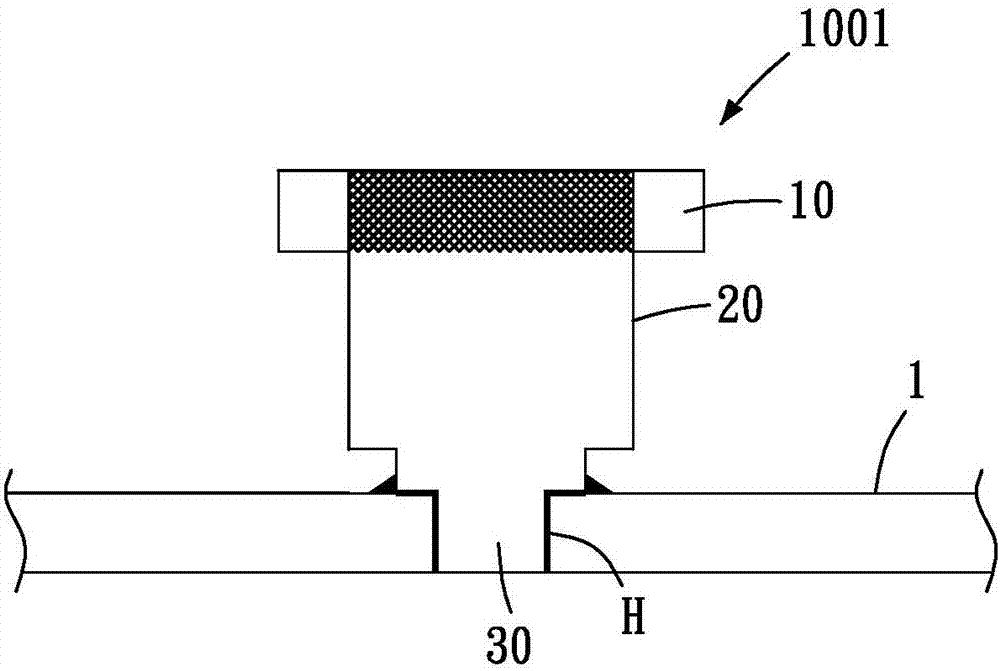

[0093] Please refer to Figure 1A , which is a schematic diagram of the first embodiment of the handle assembly 1000 of the present invention. After the handle assembly 1000 is fixed on an object 1, the user can lift the object 1. The handle assembly 1000 includes from top to bottom: a lifting part 10; a body part 20 connected to the lifting part 10 and a fixing portion 30 connected to the bottom of the body portion 20 . Wherein, the object 1 is a PCB board, a metal object or a plastic object. In addition, the lifting part 10 and the main body part 20 are integrally formed, but not limited thereto, and may also be formed in combination, such as Figure 1B shown; Figure 1B It is a schematic diagram of the second embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com