Sample plate fixation clamp tool

A tooling and template technology, applied in the field of fixture tooling for fixed templates, can solve problems such as low efficiency, inconvenient use, and unobjective detection results, and achieve the effect of improving detection efficiency, objectivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solution will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

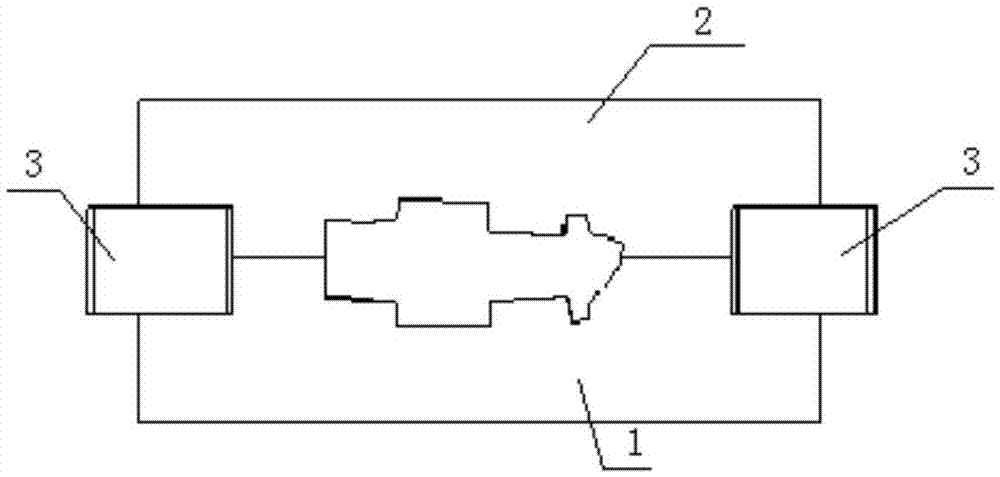

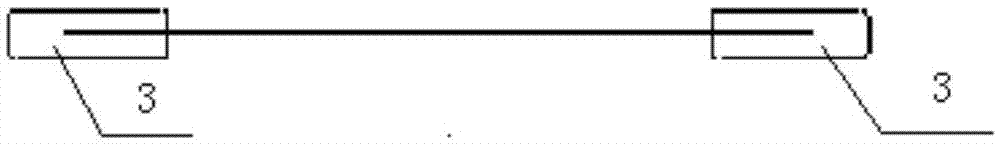

[0010] Such as figure 1 and figure 2 As shown, the tooling is U-shaped, and the U-shaped groove is in clearance fit with the sample plate to be fixed. A special fixture with the same thickness as the sample plate is processed on a tooling plate, and the size and size of the tooling U-shaped fixture 3 are in the groove. Now put the lower sample plate 1 into the groove, and then put the upper sample plate 2 in a suitable position. It is inserted into the matching area on both sides of the upper and lower templates, which can realize the simultaneous fixation of the upper and lower templates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com