A workpiece bending device

A bending device and workpiece technology, applied in the field of workpiece bending, can solve problems such as low processing efficiency, high operation risk, and potential safety hazards, and achieve the effects of low manufacturing cost, high precision, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

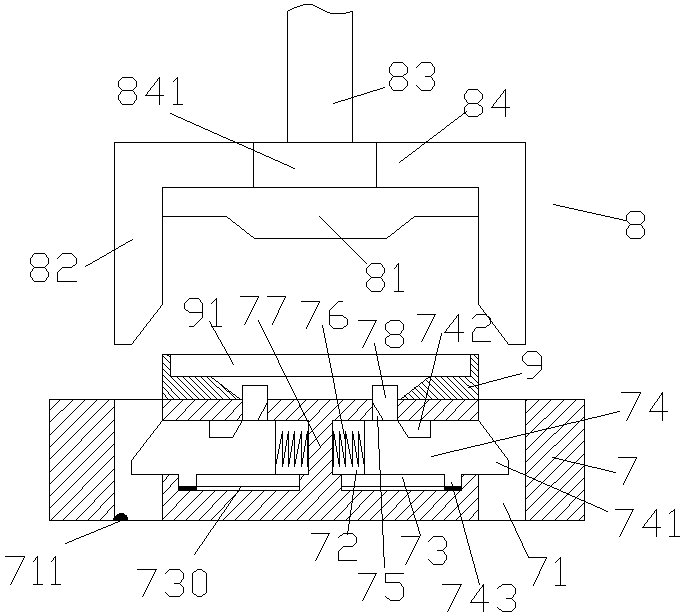

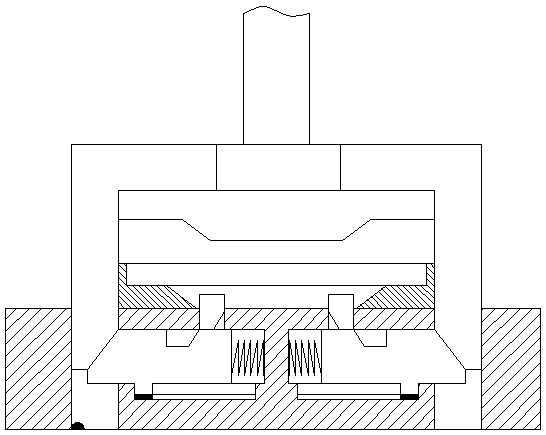

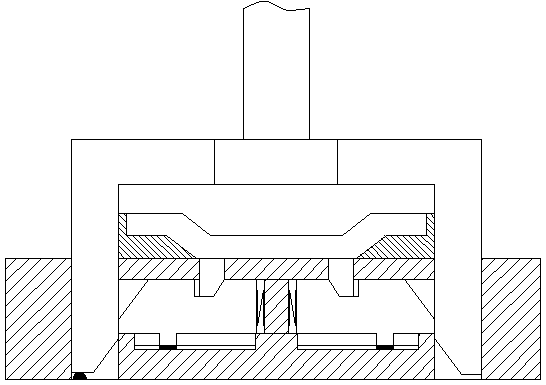

[0020] Such as Figure 1-Figure 4 As shown, a workpiece bending device of the present invention includes a manipulating part 8 and a base part 7 arranged at the lower end of the manipulating part 8, and the manipulating part 8 includes a pressing arm 84, an upper template 81 and a driving arm Rod 83, both ends of the pressing arm 84 are fixed with inserting shafts 82 extending downwards, the upper part of the base part 7 is provided with a lower template 9 corresponding to the upper template 81, and the inserting shafts The base part 7 corresponding to the lower end of 82 is provided with a slot 71 for cooperating with the insertion shaft 82, and the base part 7 between the slots 71 is provided with sliding parts corresponding to the left and right. Slots 72, spacers 77 fixedly connected to the base part 7 are arranged between the sliding grooves 72, and the upper part of each sliding groove 72 is provided to pass through the body of the base part 7 and connect with the base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com