Automobile chassis beam multi-position riveting frame

A car chassis and multi-station technology, applied in the field of fixtures, can solve the problems of reducing production efficiency and product quality, and achieve the effects of improving work efficiency, saving production costs, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail by embodiment:

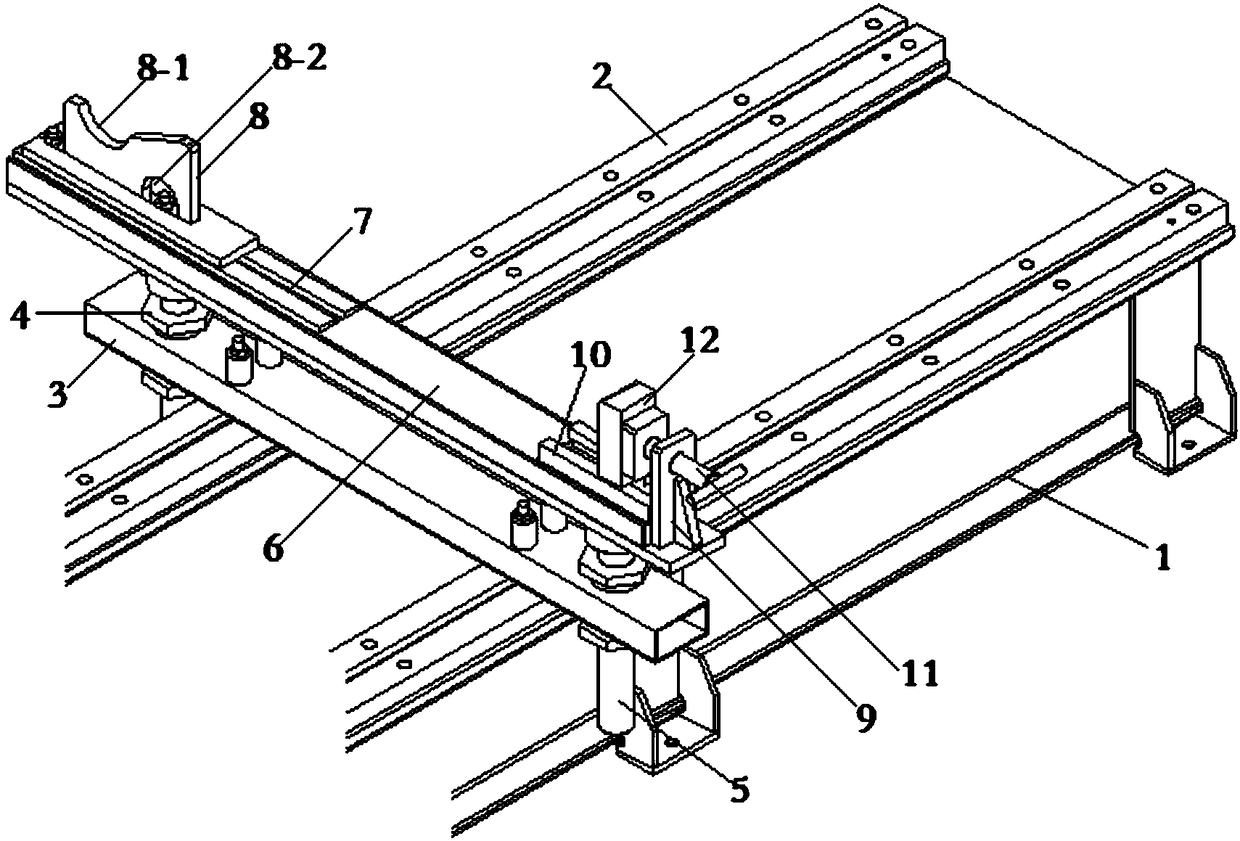

[0013] The multi-position riveting frame for the crossbeam of the automobile chassis includes a base 1 composed of several components. The upper end of the base 1 is a slide rail 2. A slide beam 3 is arranged on the slide rail 2. The slide beam 3 is slidably installed on the slide through a fixedly installed slider. On the rail 2, both ends of the sliding beam 3 are provided with perforations and an adjusting sleeve 4 is installed for rotation. The center of the adjusting sleeve 4 is provided with a thread and screwed with the adjusting rod 5. The upper ends of the two adjusting rods 5 are fixedly installed with a mounting seat 6, and the mounting seat The left end of 6 is provided with draw-in groove 7 and is fixedly installed with overturning hanging plate 8, the right end is fixedly installed stand 9 and adjustment seat 10 by bolt, and stand 9 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com