Paper Feed Roller

A paper feeding roller and axial direction technology, applied in the direction of object separation, object supply, pile separation, etc., can solve the problems of friction coefficient reduction, unable to stabilize paper conveying, etc., and achieve the effect of suppressing sound

Inactive Publication Date: 2017-06-23

YAMAUCHI CORP

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] If paper dust or its own wear debris remains on the surface, the friction coefficient of t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Login to view more

Abstract

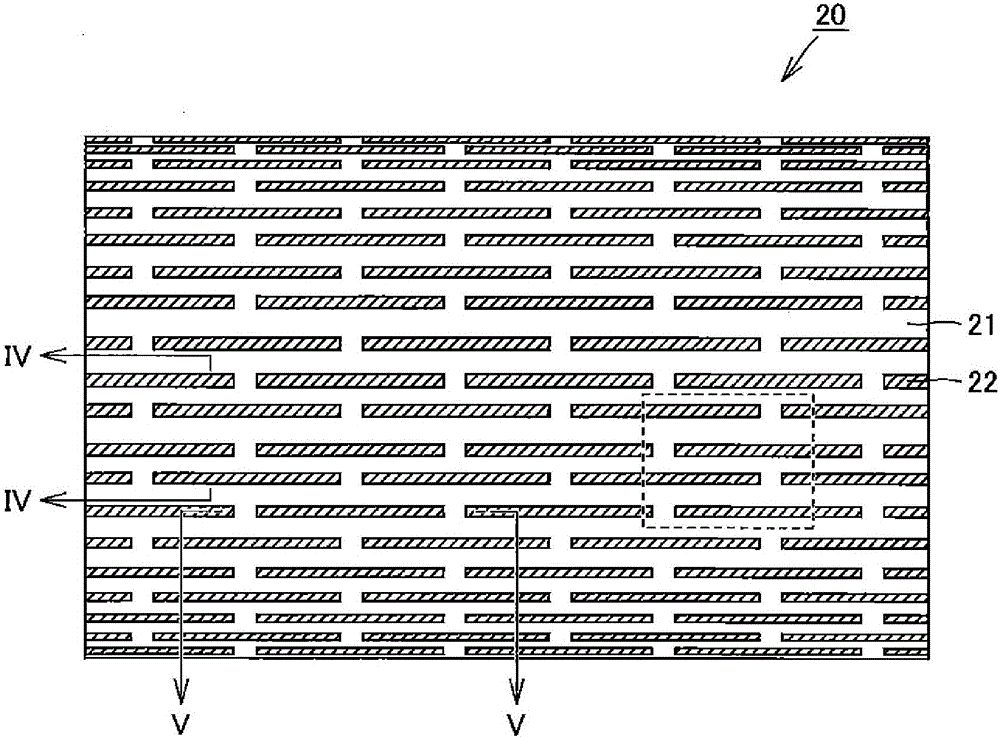

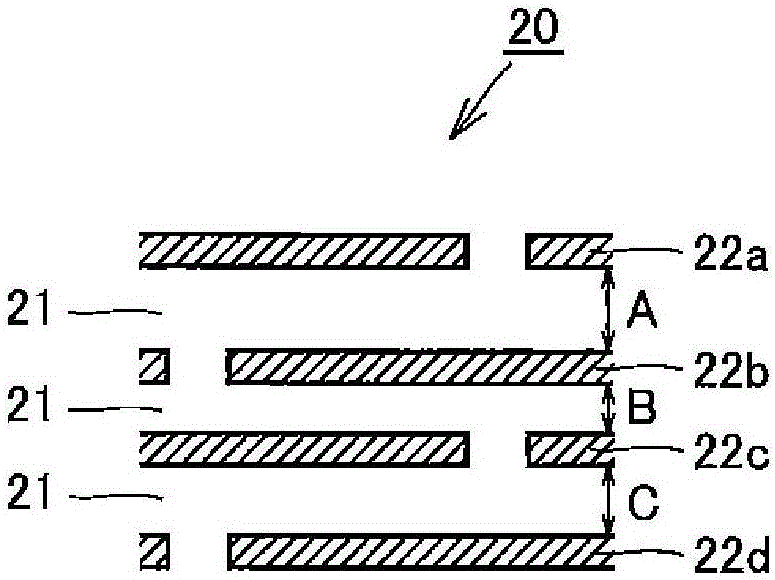

To provide a paper feed roller which effectively suppresses sound squeak. A paper feed roller provided with a land part (21) and plural axial grooves (22). The plural axial grooves (22) intermittently extend along an axial direction, and are provided at intervals on a circumferential direction. A space between adjacent axial grooves (22) in the circumferential direction is equal to or less than 2 mm, and a surface roughness Rz of a cylindrical surface (21) of the land part is equal to or more than 10 mum.

Description

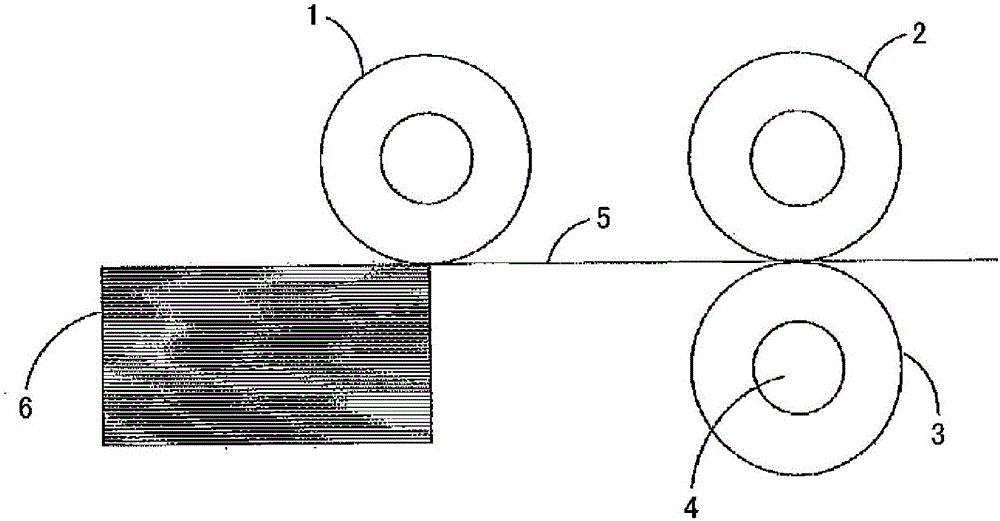

technical field [0001] The invention relates to a paper feeding roller, in particular to a paper feeding roller of copiers, printers, facsimile machines and other equipment. Background technique [0002] The paper feeding section of equipment such as copiers, printers, and facsimile machines includes pickup rollers, feed rollers, retard rollers, and the like for feeding paper sheets one by one. [0003] For example, in figure 1 In the FRR paper feeding device shown, the paper 5 is conveyed from the paper cassette 6 to the separation part by the pick-up roller 1, and in the separation part, the paper 5 is prevented from being multi-feed by the retard roller 3, wherein the retard roller 3 includes The torque limiter 4 is provided so as to press against the feed roller 2 . That is, when a paper feed command is issued, the pickup roller 1 and the feed roller 2 start to rotate. At this time, the retard roller 3 that presses against the feed roller 2 also rotates together with ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B65H3/06B65H5/06

CPCB65H3/06B65H5/06B65H2401/114B65H2404/1118B65H2404/192

Inventor 鬼塚智之山本达也

Owner YAMAUCHI CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap