Gas injector with non-elastomer seal seat

A gas injector and sealing seat technology, which is used in machines/engines, charging systems, combustion engines, etc., can solve problems such as valve needle acceleration, sealing seat strength loss, valve needle vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

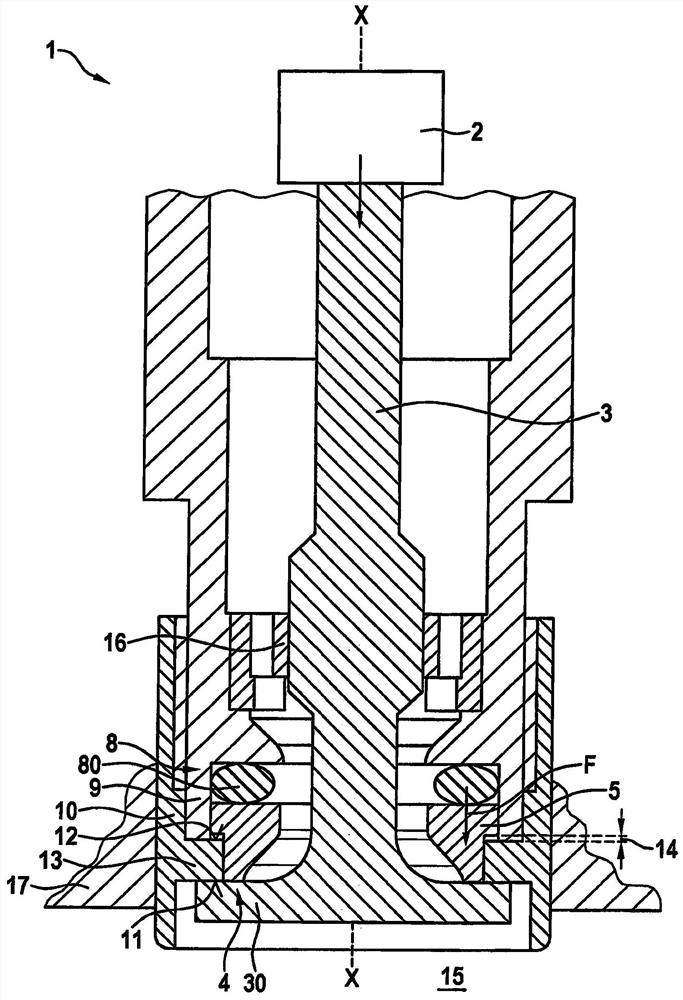

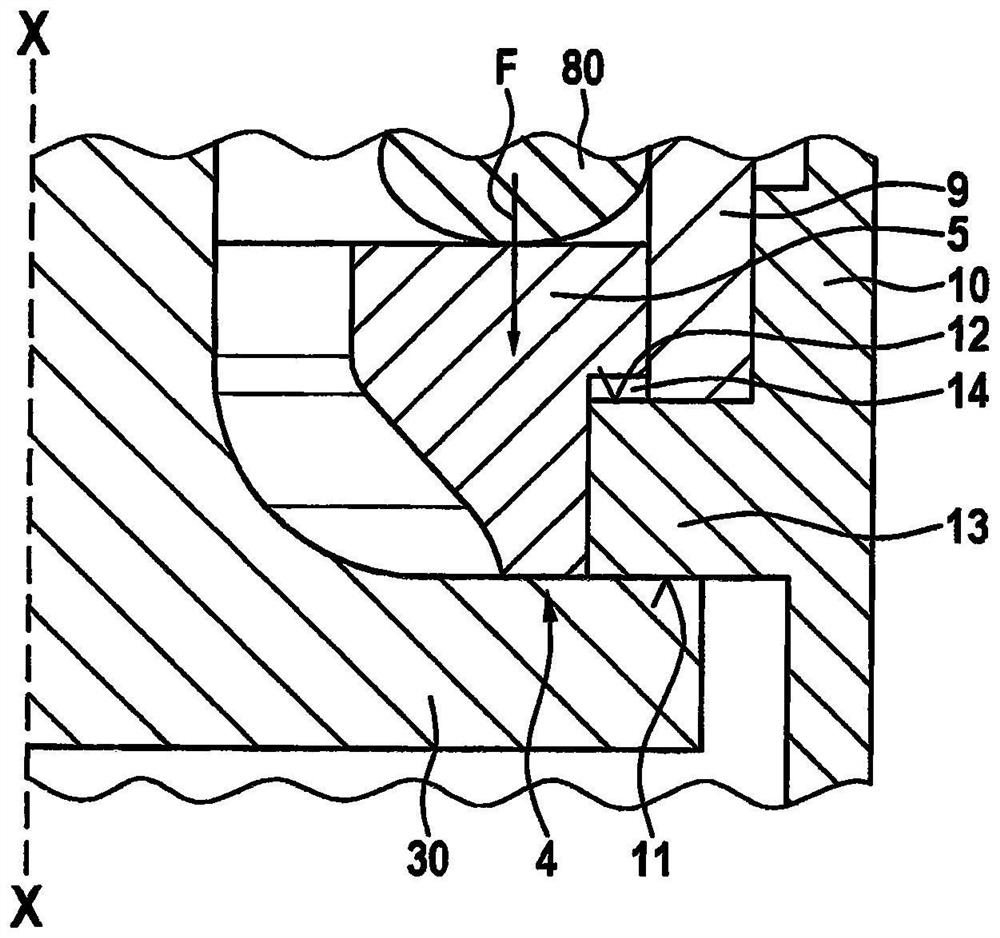

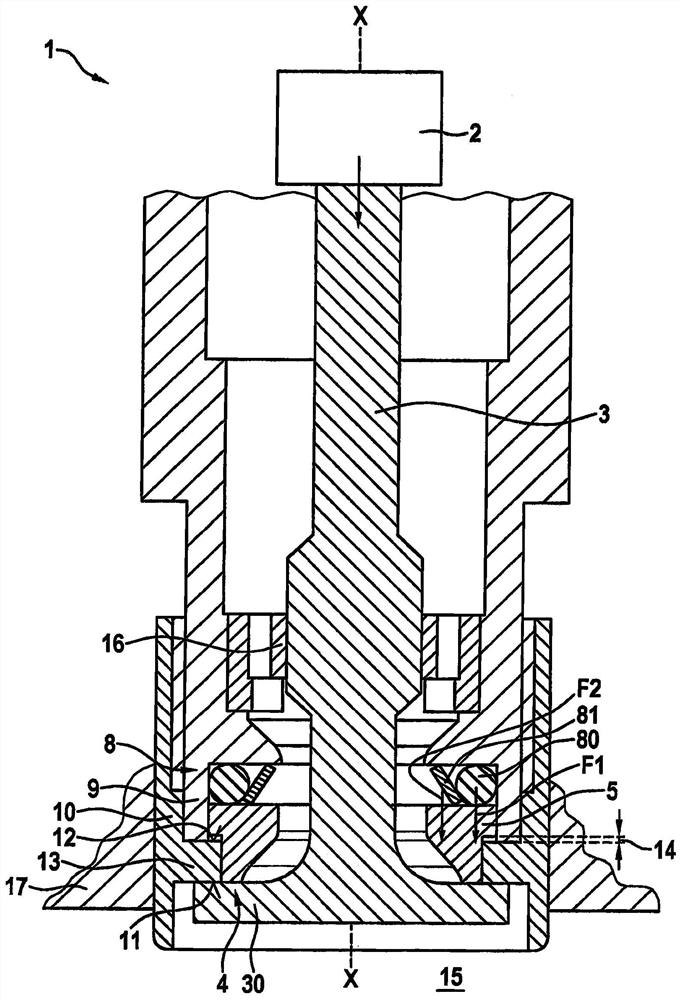

[0023] Subsequent reference figure 1 and figure 2 Details A gas injector 1 according to a first preferred embodiment of the invention is described.

[0024] Such as figure 1 As stated, the gas injector 1 comprises an actuator 2 , which is only shown schematically. The actuator 2 is connected to a valve mechanism 3 , in this embodiment a valve needle with a valve disk 30 .

[0025] The valve mechanism 3 is also guided by means of a guide element 16 .

[0026] The gas injector 1 also includes a sealing seat 4 which is arranged between the movable sealing element 5 and the valve disk 30 . The sealing seat 4 is a flat sealing seat and is arranged as far as possible on the outer periphery of the valve disk 30 . Furthermore, a first stop 11 is arranged on the annular region 13 of the housing sleeve 10 . The first stop 11 is a metallic stop between the valve disk 30 and the annular region 13 . The first stop 11 is here radially outside the sealing seat 4 . The second stop 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com