Demoulding device for injection mould of heavy-duty automobile

A technology for injection molds and heavy vehicles, which is applied in the field of automotive injection parts and can solve problems such as the difficulty in returning wedge-shaped sliders and ejector plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

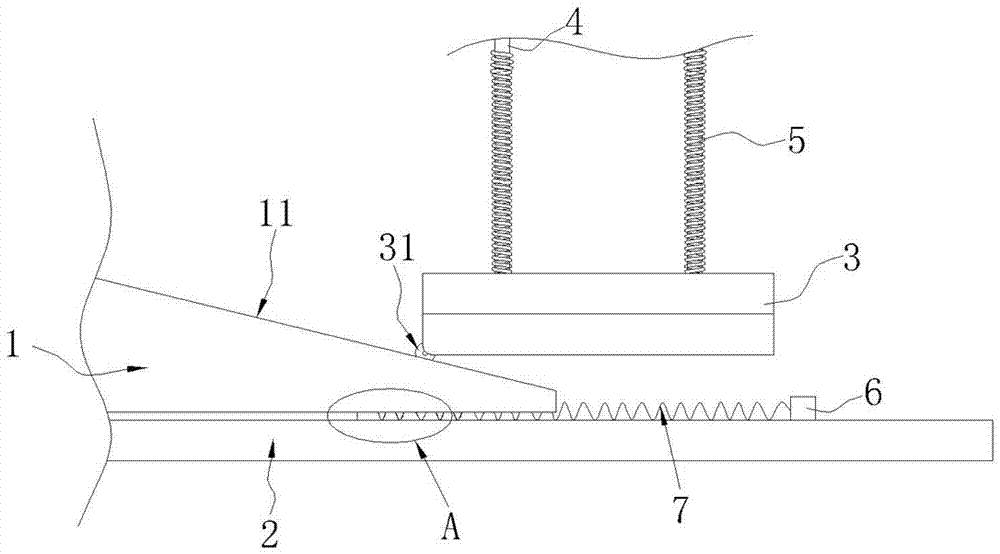

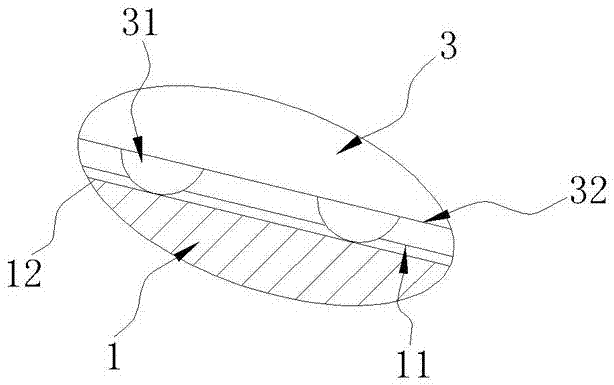

[0019] Example 1: as figure 1 , figure 2 As shown, a demoulding device for an injection mold of a heavy-duty vehicle includes a wedge-shaped slider 1 and a thimble plate 3 located on the front side of the wedge-shaped slider inclined surface 11. Below the wedge-shaped slider 1 is a slide rail for the wedge-shaped slider 1 to slide. 2. A number of thimbles 5 are arranged above the thimble plate 3 for ejecting the plastic parts of the bumper, and the thimble 5 is covered with a thimble return spring 5; A roller 31 is arranged to roll relative to the inclined surface 11 of the wedge-shaped slider, and there is a groove 12 on the inclined surface 11 of the wedge-shaped slider (see Figure 4 ), so that the rollers 31 can roll in the grooves 12. Of course, the grooves 12 can also be replaced with protrusions, so that the rollers 31 can be distributed on both sides of the protrusions.

[0020] In order to enable the wedge-shaped slider 1 to return to the initial position after th...

Embodiment 2

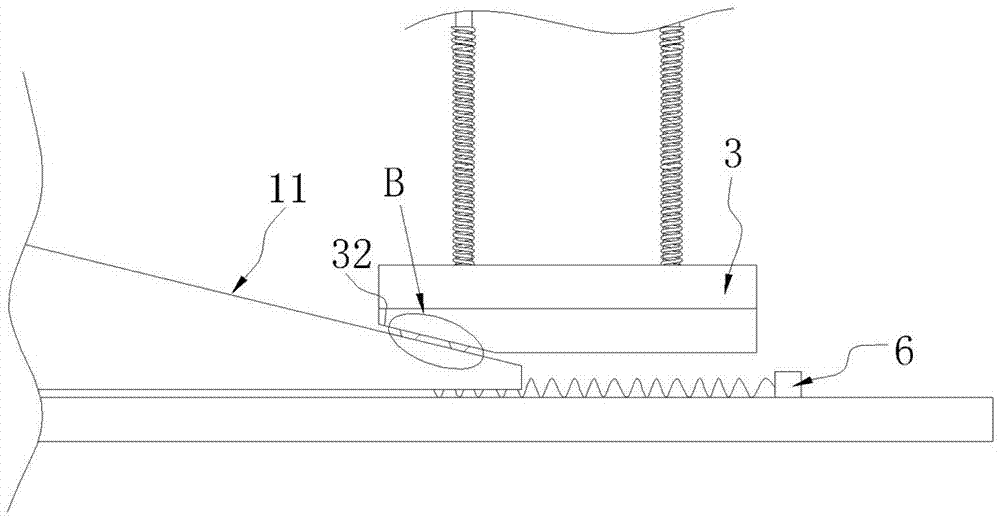

[0023] like image 3 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the ejector pin plate 3 is provided with a reverse wedge surface 32 that matches with the slope 11 of the wedge slider, and the pulley 31 is fixed on the reverse wedge surface 32, so that the reverse More pulleys 31 can be arranged on the wedge-shaped surface 32 . In order to further improve the stability of rolling friction, the pulley 31 is specifically a pulley set composed of a plurality of single pulleys, which can make the mutual movement between the wedge-shaped slider 1 and the ejector plate 3 smoother.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com