Double-wrapped parallel yarn spinning device and spinning method

A technology of wrapping yarn and wrapping yarn, applied in the direction of yarn, textile and papermaking, can solve the problems of spinning variety and yarn quality limitation, and achieve the effect of increasing added value and enriching the appearance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

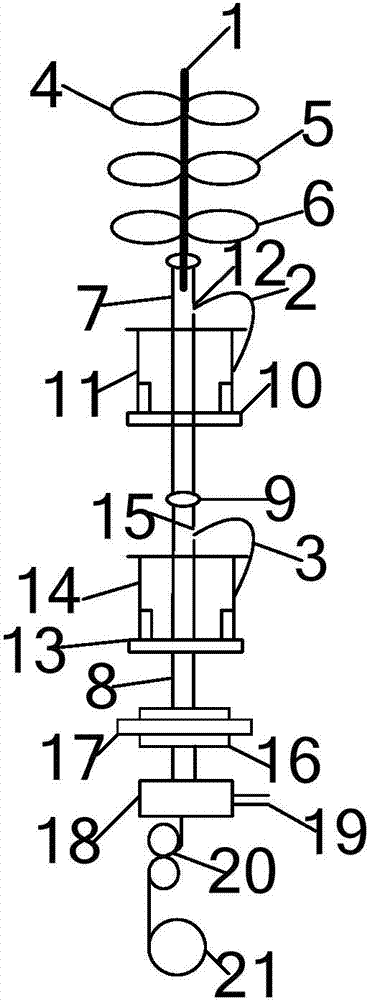

[0014] Such as figure 1 As shown, a double-wrapping parallel yarn spinning device includes a drafting device. The drafting device includes a pair of rear rollers 4, a pair of middle rollers and a pair of front rollers 6, and an upper hollow spindle 7 is arranged at the bottom of the drafting device. , a lower hollow spindle 8 is arranged on the lower part of the upper hollow spindle, the top of the upper hollow spindle is open, and an upper pallet 10 is fixedly connected to the outer circumference of the upper hollow spindle. On the upper embedded pin, the upper yarn bobbin 11 is placed on the upper tray, the bottom end of the upper yarn bobbin is fixedly embedded in the upper embedded pin, and the upper outer covering yarn 2 is wound on the upper yarn bobbin, and the upper hollow yarn 2 located at the upper part of the upper yarn bobbin There is an upper feeding hole 12 on one side of the spindle, and a lower tray 13 is fixedly connected to the outer circumference of the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com