A double-layer wrapped yarn and a production method therefor

A wrapping yarn, double-layer technology, applied in the direction of yarn, spinning machine, textile and paper making, can solve the problems of spinning variety and quality limitation of yarn, achieve rich appearance style, increase product added value, increase cost The effect of yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

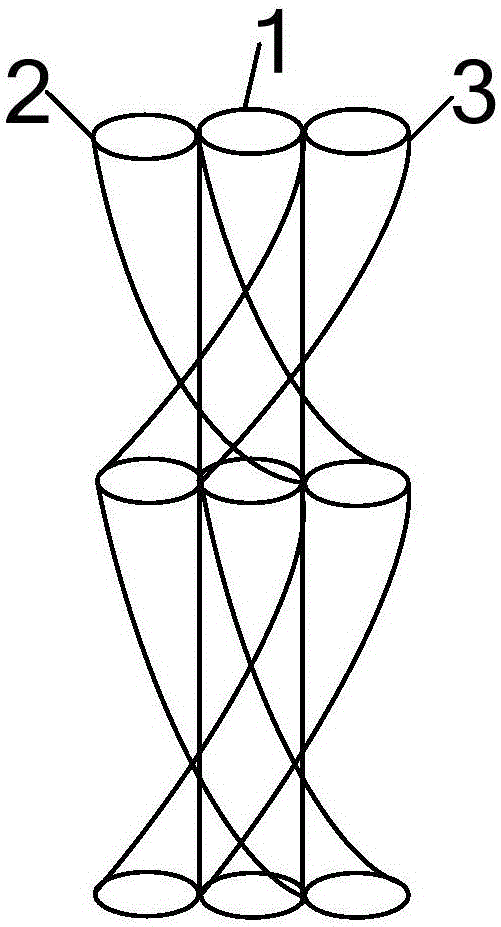

[0012] Such as figure 1 and figure 2 As shown, a double-layer wrapping yarn includes an inner core yarn layer 1 and an outer wrapping layer, the inner core yarn layer is a spun yarn with a weak twist, and the outer wrapping layer includes a first wrapping yarn 2 and a second wrapping yarn Yarn 3, the first wrapping yarn and the second wrapping yarn are short fiber spun yarns or chemical fiber filaments, the first wrapping yarn is Z-twisted and wrapped outside the inner core yarn layer to obtain a single-layer wrapping yarn, the second wrapping yarn The wrapped yarn is wrapped in an S twist direction on the outside of the single-layer wrapped yarn to obtain a double-layer wrapped yarn.

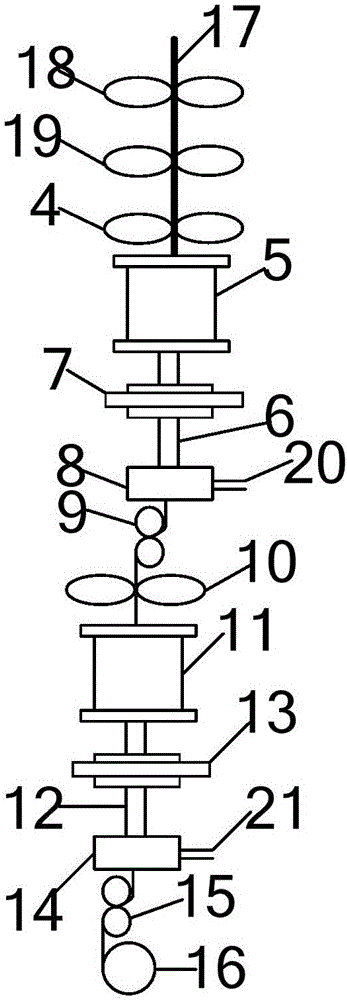

[0013] In order to realize the production of the above-mentioned double-layer wrapping yarn, the following production method is adopted, including a first-stage spinning device and a second-stage spinning device, the first-stage spinning device and the second-stage spinning device are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com