Silk-screen printing flexible sensor process

A flexible sensor and screen printing technology, applied in the field of flexible sensors, can solve problems such as poor consistency and difficulty in applying wearable devices, and achieve the effects of avoiding falling off or damage, good consistency, and strong firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

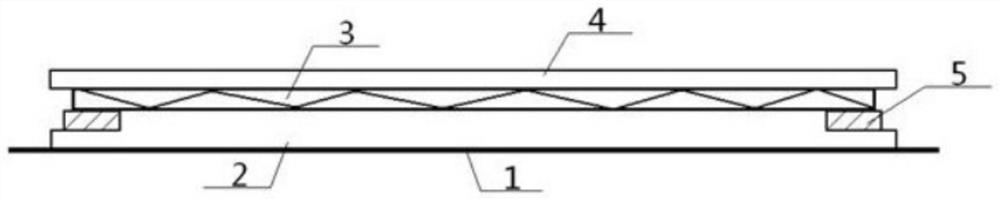

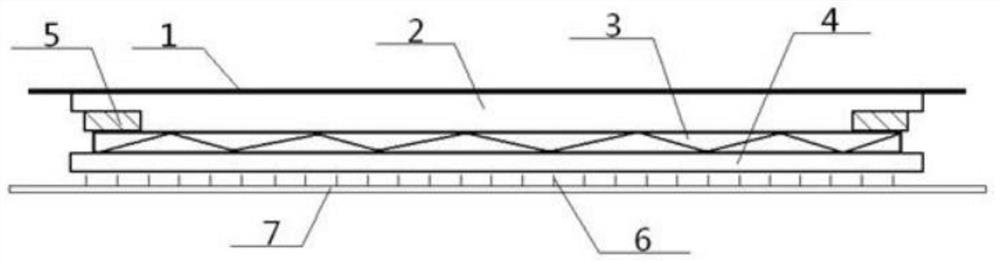

[0047] see figure 1 - image 3 , a stable screen printing flexible sensor, including a cloth 1, an inner adhesive layer 2, a sensor 3, an outer adhesive layer 4 and a conductive unit 5; the outer surface of the cloth 1 and the inner surface of the inner adhesive layer 2 connected, the outer surface of the inner adhesive layer 2 is connected with the inner surface of the sensor 3, the outer surface of the sensor 3 is connected with the inner surface of the outer adhesive layer 4, and the outer surface of the outer adhesive layer 4 is in contact with the atmosphere, And the sensor 3 is connected with the conductive unit 5 . The sensor 3 is preferably a strain sensor, and its application method is screen printing. More preferably, the sensor 3 is graphite, carbon black or metal powder.

[0048] A manufacturing process of above-mentioned stable screen printing flexible sensor, said manufacturing process comprises the following steps in sequence:

[0049] First place the film 7 ...

Embodiment 2

[0051] Basic content is the same as embodiment 1, the difference is:

[0052] The conductive unit 5 is located between the sensor 3 and the inner adhesive layer 2 , and the inner surface of the outer adhesive layer 4 covers the outer surface of the sensor 3 . The cloth 1, the inner adhesive layer 2, and the outer adhesive layer 4 are all flat, and the cloth 1, the inner adhesive layer 2, and the outer adhesive layer 4 are parallel to each other.

Embodiment 3

[0054] Basic content is the same as embodiment 1, the difference is:

[0055] The inner adhesive layer 2 is hot-melt glue, and the outer adhesive layer 4 is colored silica gel; the outer adhesive layer 4 is provided with fluff or printing. The conductive unit 5 is a conductive wire, a conductive sheet or a metal conductive buckle, and when it is a conductive wire, it can be a silver wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com