Modularization design matrix type electric connector

A modular design, electrical connector technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve problems such as difficulties, difficult management and maintenance, complicated test connections, etc., to solve the complicated connection , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

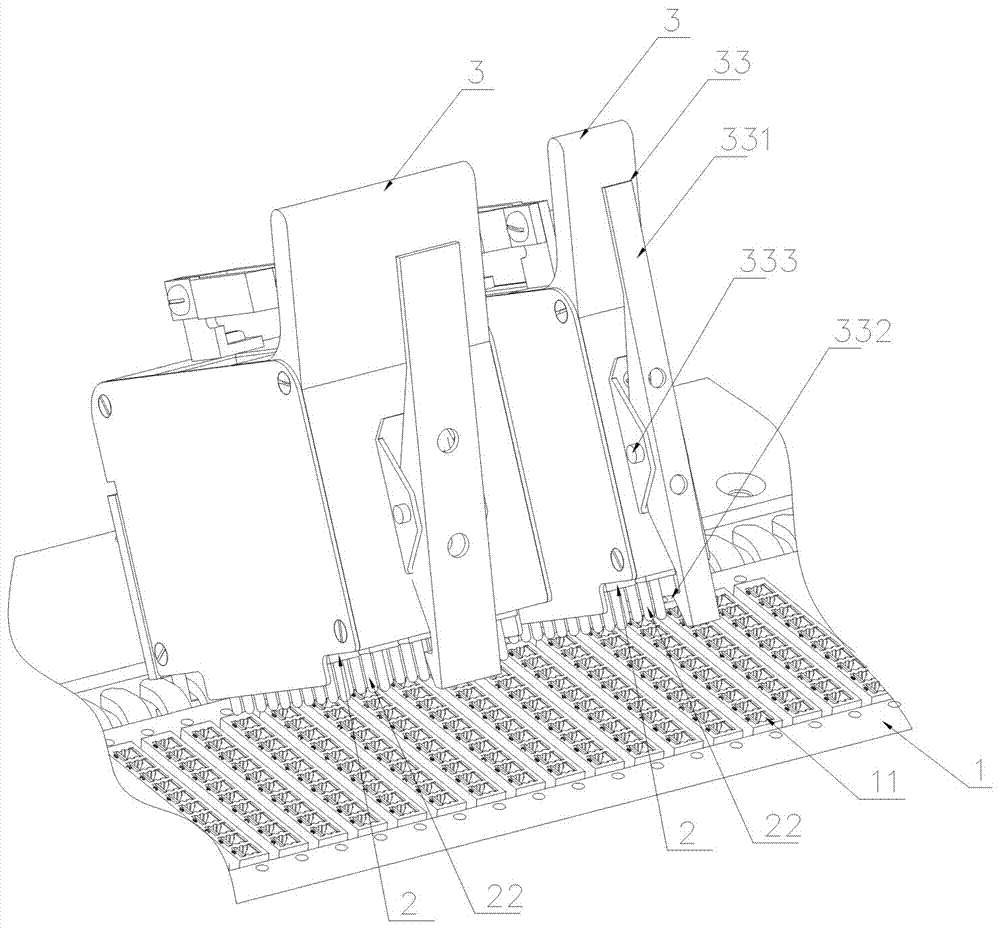

[0021] refer to figure 1 , The standard socket 1 of the present invention is provided with multiple socket holes 11, and the socket holes 11 are arranged in a matrix in rows and columns.

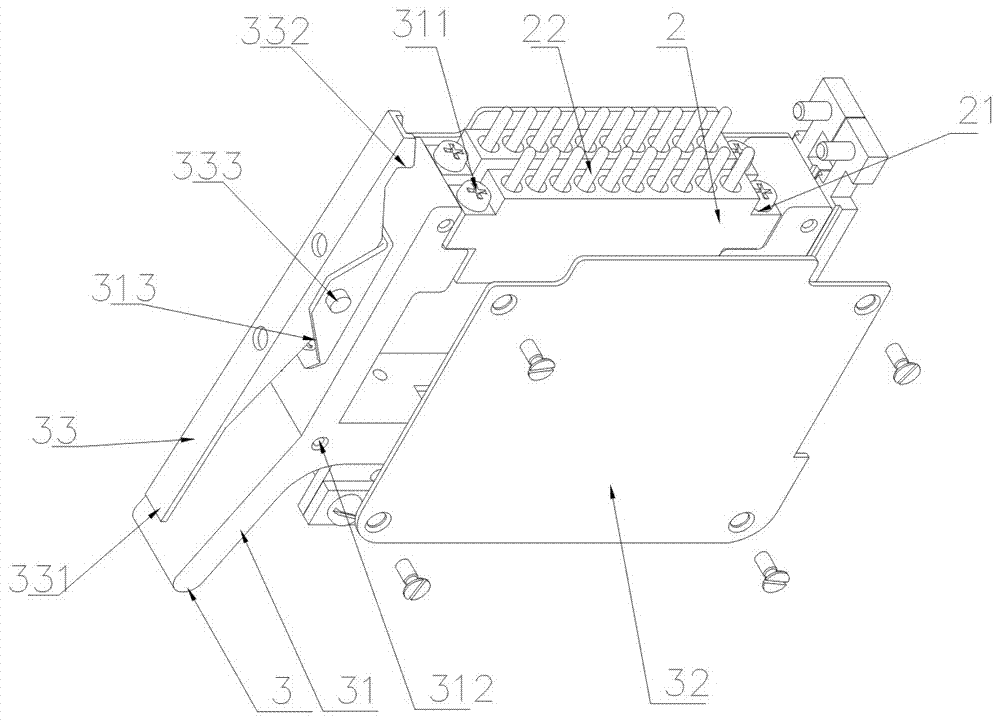

[0022] refer to figure 2 , image 3 , Figure 4 , the plug of the present invention is composed of a contact seat 2 and a plug housing 3; the present invention arranges several contacts 22 arranged in sequence on the contact seat 2, and the position between the contacts 22 is the same as that of each row of multiple sockets on the standard socket 1. The positions of the holes 11 correspond to each other;

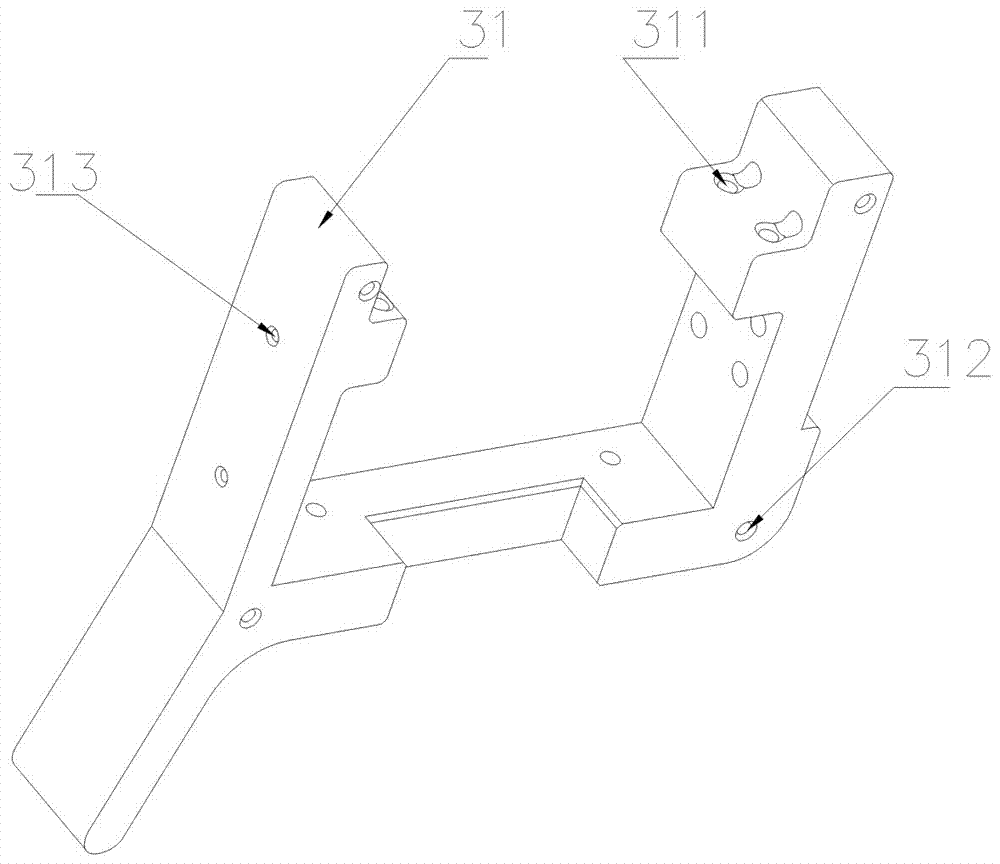

[0023] In the present invention, one or more contact pieces 2 are arranged side by side on the bracket 31 of the plug housing 3 in sequence, and the contact pieces 2 are arranged side by side behind the plug casing 3, between the contacts 22 on two adjacent contact pieces 2 The position corresponds to the position of each row of multi-socket holes 11 on the standard socket 1;

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com