Automatic detecting and packaging machine for shielding shell

An automatic detection and packaging machine technology, used in packaging, measuring devices, packaging protection, etc., can solve the problems of flatness variation, low efficiency of detection methods, and high requirements for flatness of welding surfaces, avoiding re-variation and improving detection and packaging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

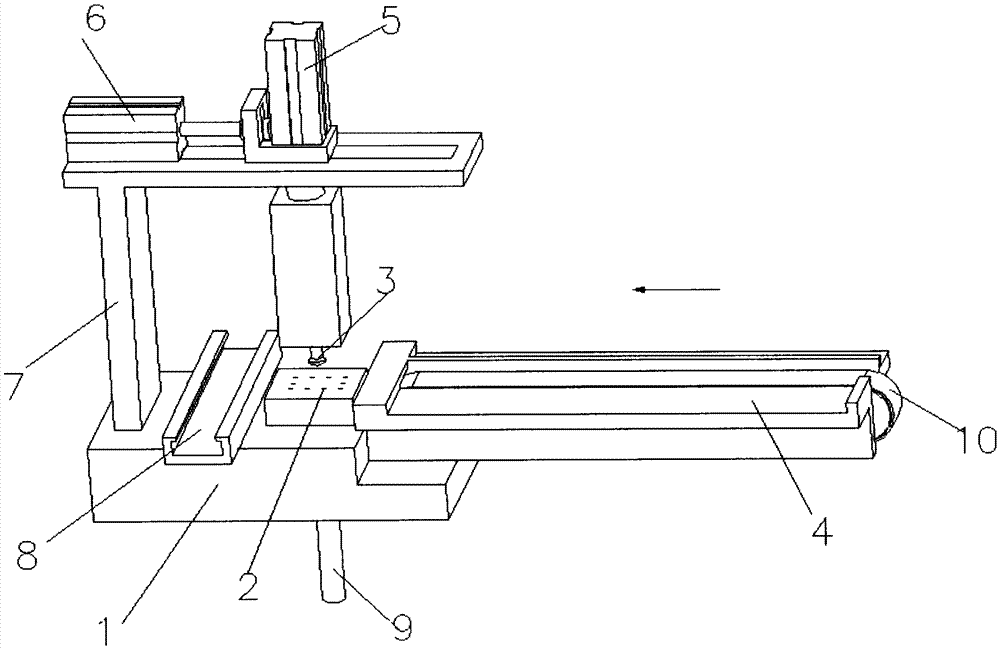

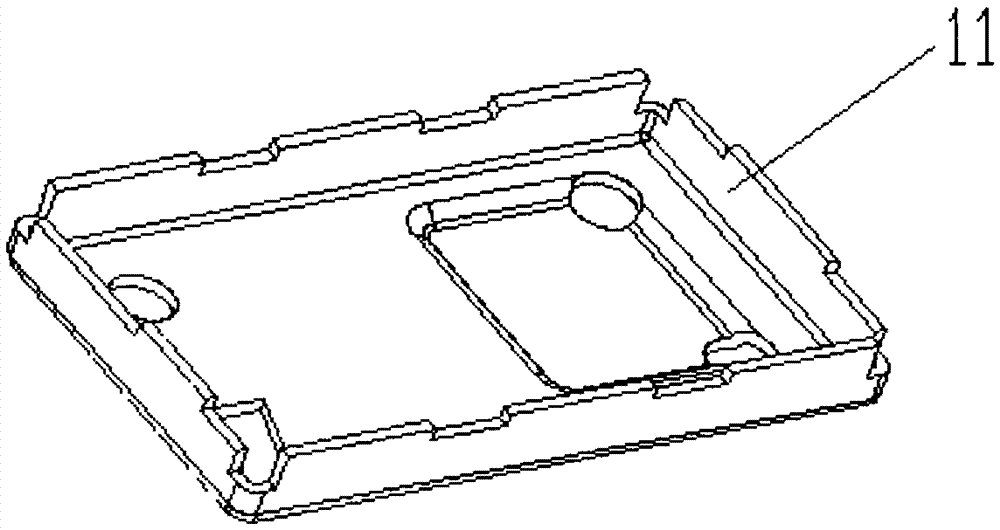

[0016] See figure 1 and figure 2 As shown, a shielding shell automatic detection packaging machine has a workbench 1, an optical fiber detection hole 2 is arranged on the surface of the workbench 1, and a suction nozzle 3 is provided on the top of the optical fiber detection hole 2. A product placement platform 4 is arranged in the axial direction of the optical fiber detection hole 2 . The suction nozzle 3 is connected to the longitudinal pneumatic mechanism 5, and the pneumatic mechanism connection 5 cooperates with the horizontal pneumatic mechanism 6 through a cross bar. The transverse pneumatic mechanism 6 is supported by a bracket 7 , and the bracket 7 is located at the side end of the workbench 1 . A packing tape slot 8 is provided between the bracket 7 and the optical fiber detection hole 2 . The bottom of the optical fiber detection hole 2 is connected with an optical fiber input device 9 . One end of the product placing table 4 is overlapped with the workbench 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com