Lens Defect Inspection System

A defect detection and lens technology, applied in sorting and other directions, to improve the discrimination ability, save transition time, and improve the efficiency of detection and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

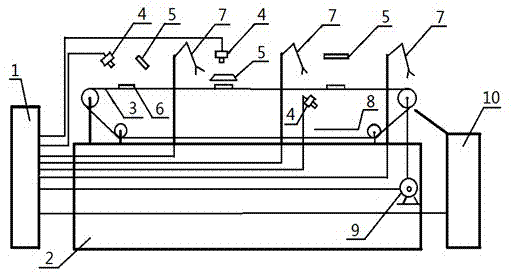

[0015] Depend on figure 1 It is a schematic diagram of the structure of the lens defect detection system of the present invention. The lens defect detection system includes information processing equipment 1, frame 2, image acquisition equipment, sorting equipment, transmission equipment and packaging printing equipment 10, the image acquisition equipment, sorting equipment and transmission equipment are arranged on the frame 2, information processing The server in the equipment is respectively connected with the image acquisition equipment, the sorting equipment, the transmission equipment, and the printing and packaging equipment.

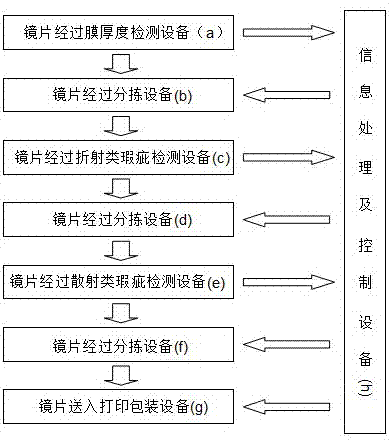

[0016] Depend on figure 2 It is known that it is a process flow chart of the lens defect detection system of the present invention. The transmission equipment sends the lens to three different sets of image acquisition equipment in sequence, and the three sets of different image acquisition equipment can acquire different defect images, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com