Device and method for preparing radioactive uranium mine standard substance

A standard material and preparation device technology, applied in the preparation of test samples, measuring devices, sampling, etc., can solve the problems of not truly representing the natural characteristics of the reference material, low degree of automation, low efficiency, etc., and achieve no dust harm to staff. , High grinding efficiency and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

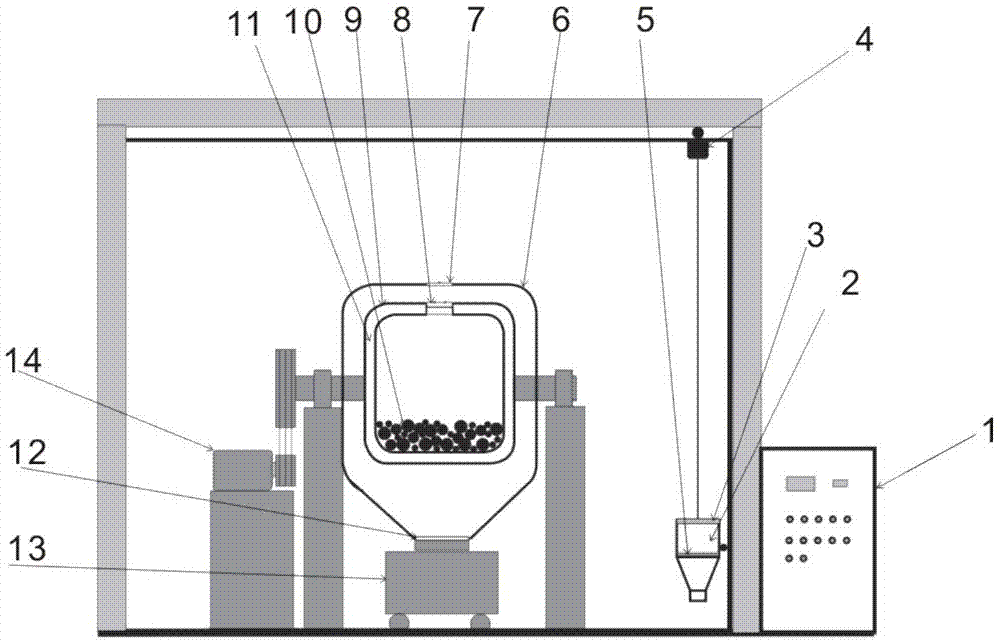

[0033] The preparation device and method of a radioactive uranium ore standard substance of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0034] A preparation device for radioactive uranium ore standard materials, including an electric control cabinet 1, a feeding tank 2, an electric transmission system 4, a dropping box 6, a ball mill 9, a discharging box 13, and a working motor 14: the feeding tank 2 is used to hold For the roughly crushed standard substance candidate samples, the electric control cabinet 1 controls the electric transmission system 4 to move the feeding tank 2 to the top of the ball mill 9 nested inside the drop box 6, and the standard substance candidate samples are transferred from the feeding tank 2 to the ball mill 9. The working motor 14 provides power supply for the ball mill 9, and the discharge box 13 is connected to the lower part of the drop box 6 to hold the prepared standard s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com