L-shaped tread mold

An L-shaped and mold technology, which is applied in the fields of mold shell/template/work frame, on-site preparation of building components, construction, etc., can solve the problems of high cost, inconvenient mold management, single mold specification, etc., and achieve cost saving, vibration reduction, etc. The effect of improving tamping efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

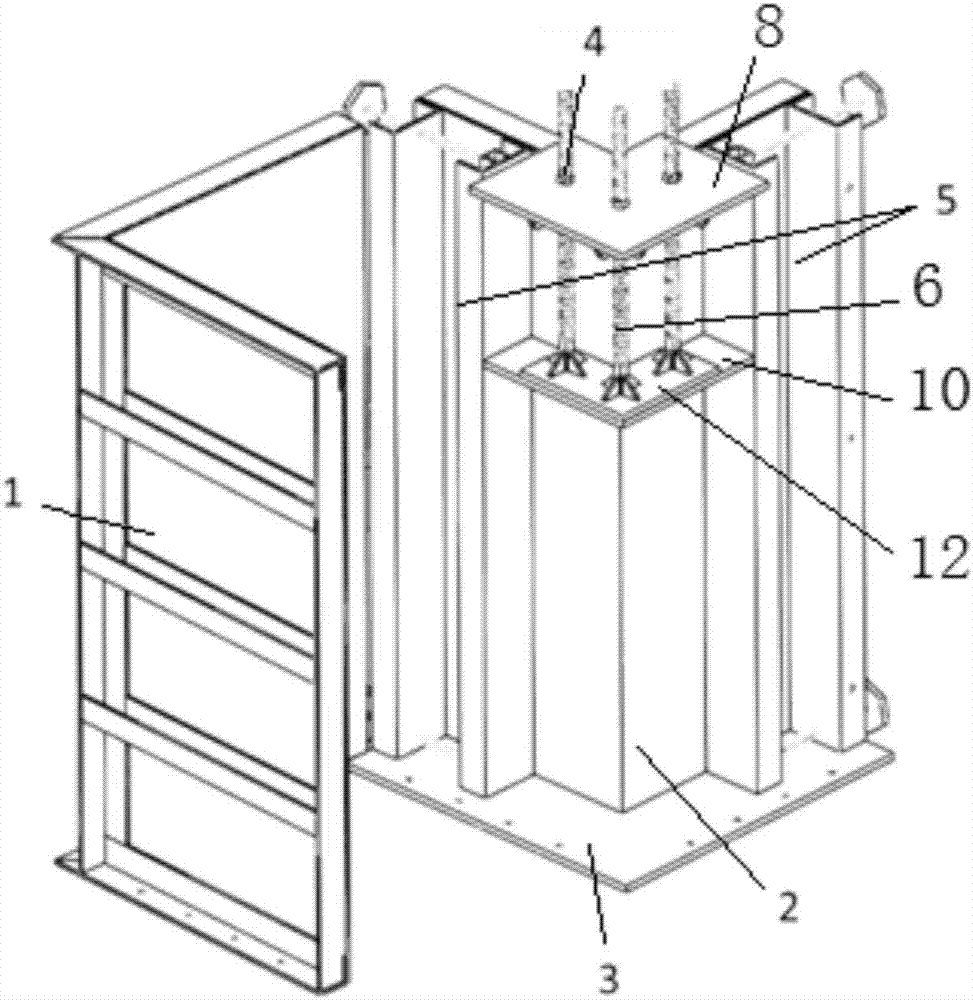

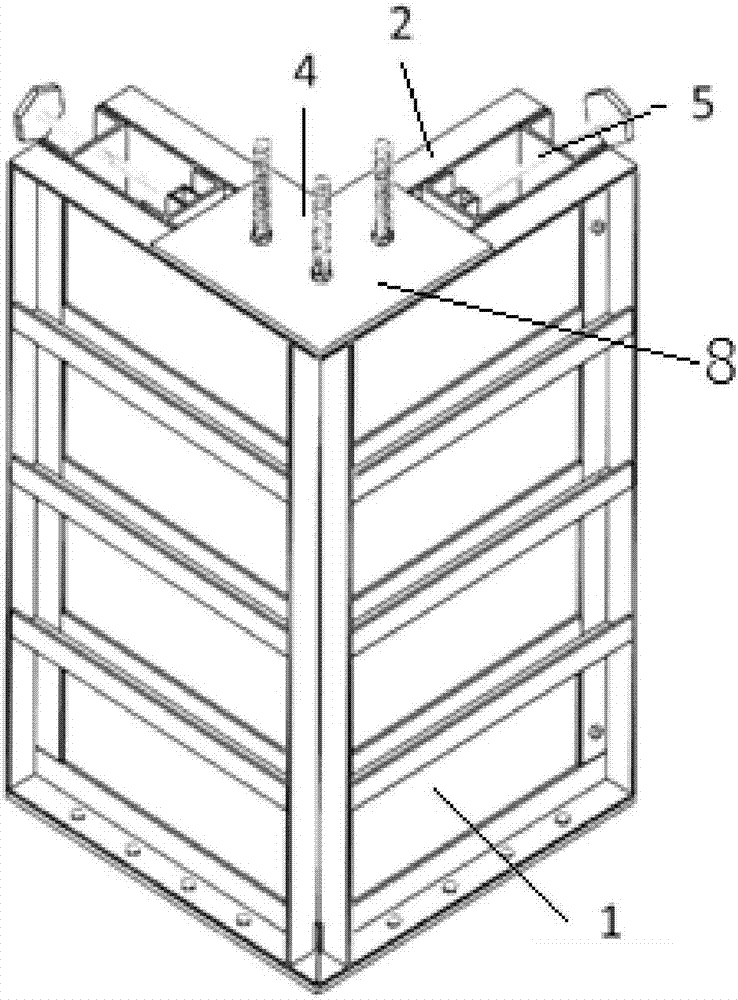

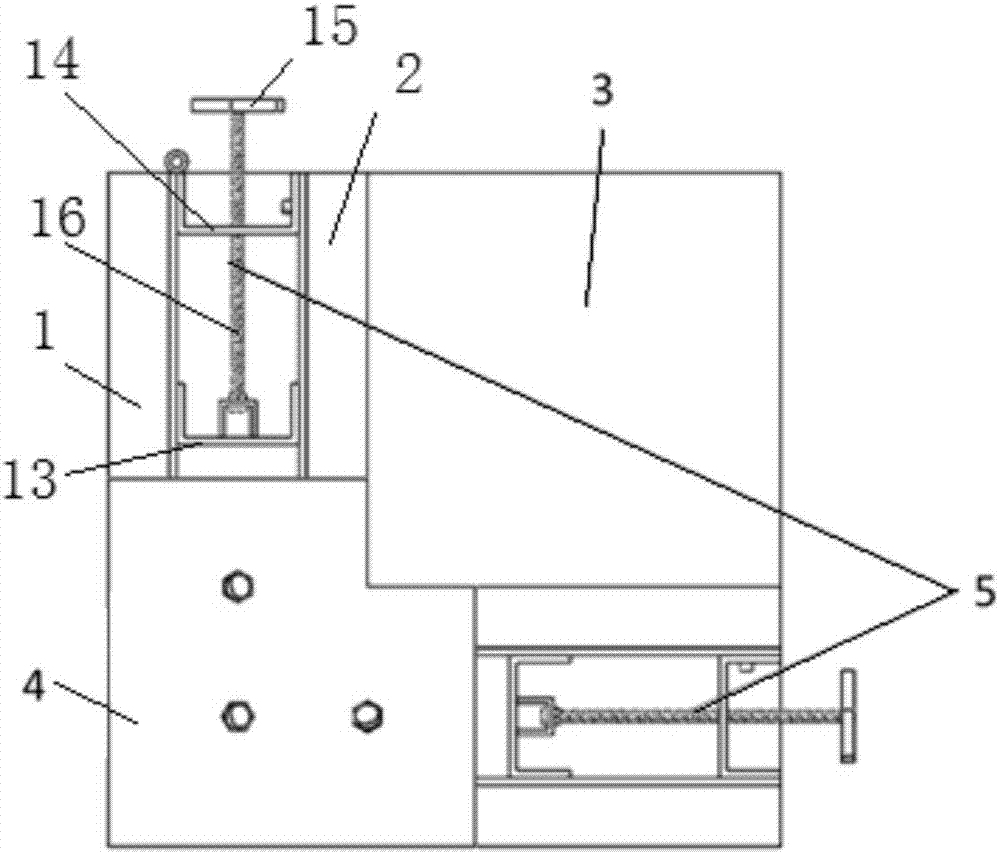

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

[0041] Such as Figure 1-Figure 6 As shown, the L-shaped stepping mold of the present invention comprises a horizontally arranged base plate 3, and the base plate 3 is fixedly connected with L-shaped clamping plate one 1 and clamping plate two 2. The inner surface of the clamping plate one 1 and the two clamping plates 2 is a plane, and Ribs are provided on the surface, the sides of clamping plate one 1 and clamping plate two 2 are perpendicular to base plate 3, and the corresponding sides of clamping plate one 1 and clamping plate two 2 are parallel, and the distance between clamping plate one 1 and clamping plate two 2 wallboards is the same as that to be The thickness of the processed L-shaped step is the same, and the thickness of the L-shaped step to be processed can be adjusted by adjusting the distance between the first splint 1 and the second splint 2, forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com