OLED display and manufacturing method thereof

A manufacturing method and display technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problem of OLED display screen being difficult to truly achieve integrated black production costs, and achieve soft, non-dazzling light and impact resistance. Unaffected strength, avoids dazzling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

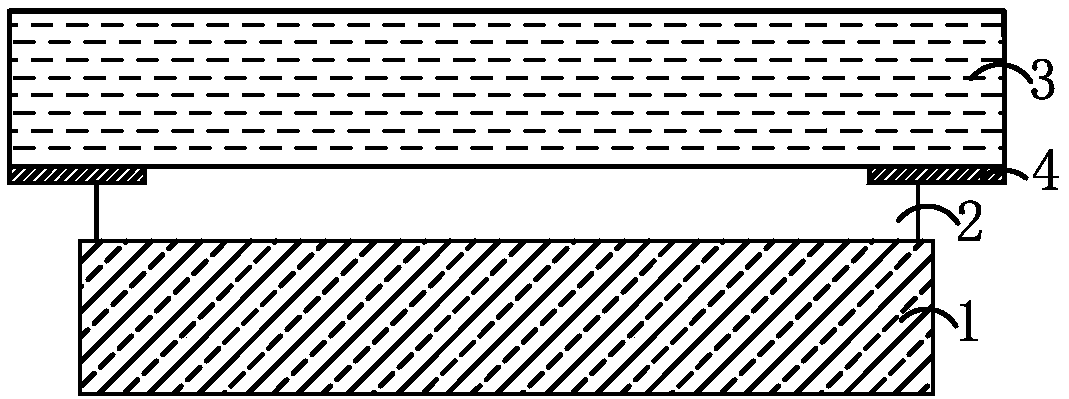

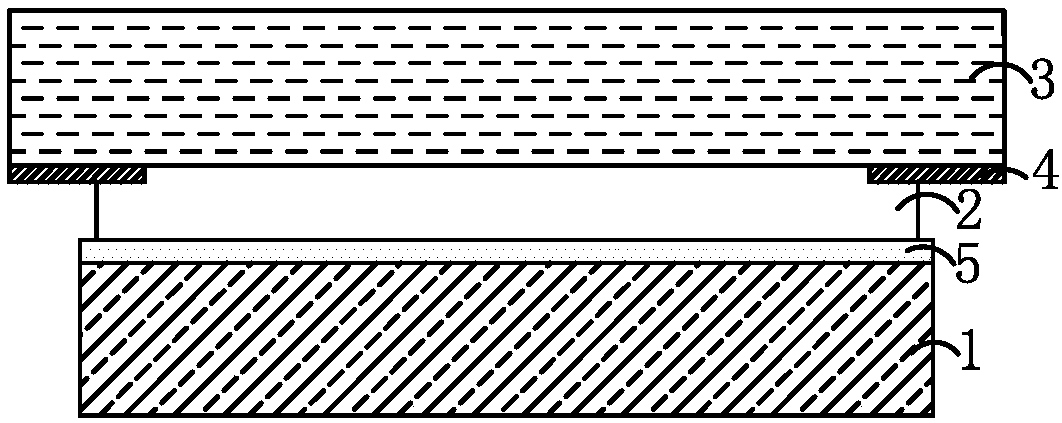

[0039] This embodiment provides an OLED display, such as figure 1 As shown, the OLED display screen includes a display module 1, an optical adhesive 2 and a cover glass 3 arranged in sequence from bottom to top, and the transmittance of the cover glass 3 to visible light is 65%. The optical glue 2 is a full lamination glue, and the optical glue 2 sticks the cover glass 3 on the display module 1 through a full lamination process.

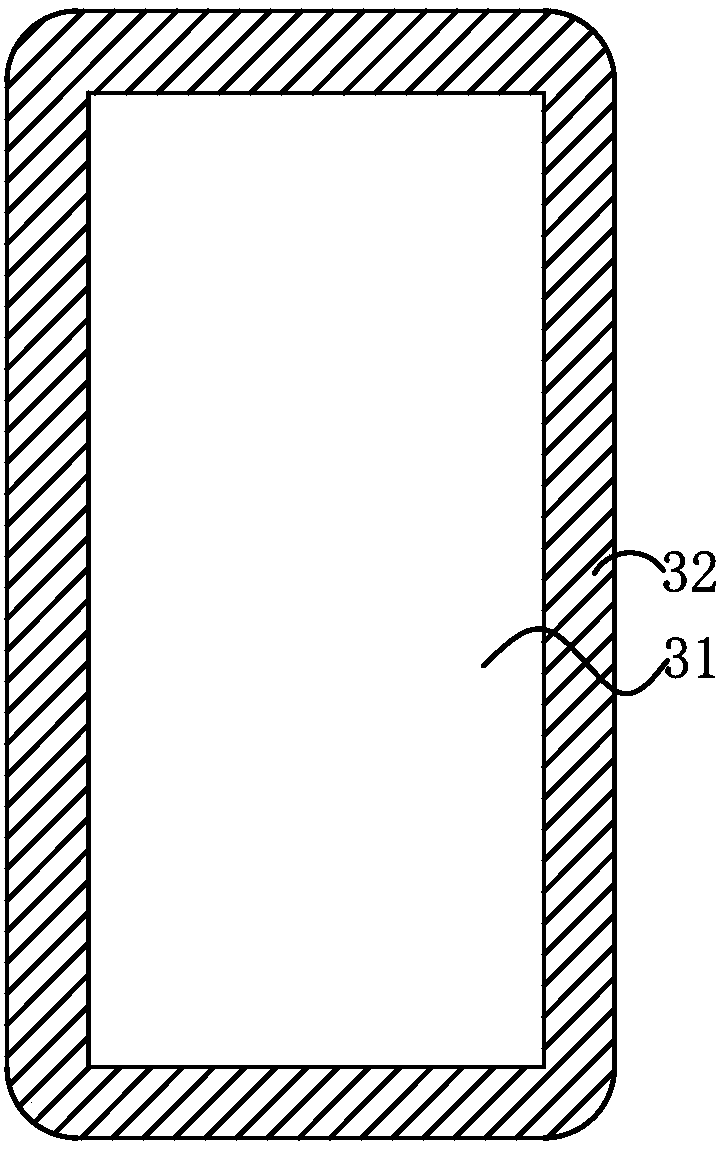

[0040] which, combined with figure 2 As shown, the cover glass 3 includes a visible area 31 located in the middle and a non-visible area 32 located around the periphery. A black ink layer is printed on the lower surface of the non-visible area 32 to form a black frame 4. The cover glass 3 is printed with The lower surface of the black frame 4 is opposite to the display module 1 . The display module 1 of this embodiment may be a display module in the prior art, and the display module 1 may only have a display function, or may have both display and ...

Embodiment 2

[0050] The difference between the present embodiment and the first embodiment is that the light transmittance of the cover glass in the present embodiment to visible light is 55%.

Embodiment 3

[0052] The difference between the present embodiment and the first embodiment is that the light transmittance of the cover glass in the present embodiment to visible light is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com