Optical cable down-lead plugging cap

An optical cable and blocking cap technology, which is applied in the field of optical cable leading and blocking caps, can solve problems such as affecting the safe operation of information communication networks, optical cable twisting, and optical cable water accumulation, saving installation and maintenance time, prolonging service life, and good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

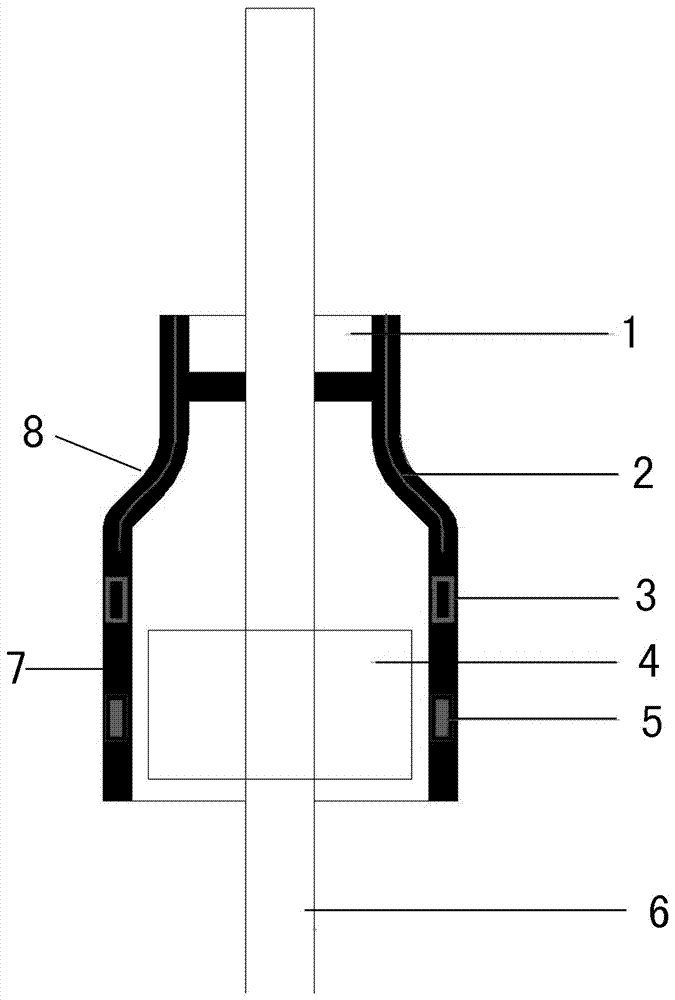

[0022] As shown in the figure, the cable lead-down blocking cap is composed of two shells 8 and an inner waterproof material layer 7; the two shells are fixed by buckles, and the buckles include rubber buckle grooves 3 and rubber buckles The buckle protrusion 5, the rubber buckle groove and the rubber buckle protrusion are elastically buckled together to avoid the problem that the rigid connection is easily broken. The seams of the two shells are snapped together, and the shell and the optical cable are sealed with a waterproof material layer at the joints of the two shells. The waterproof material layer is a waterproof cement layer, and the waterproof cement layer contains waterproof sealing strip 2. The outer surface of the shell is equipped with a ferrule, the outer surface of the ferrule is provided with a transparent window, the side of the ferrule is provided with an opening, the opening is fastened by a groove and a protrusion, the optical cable information sign 4 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com