An insulating pull rod assembly

A technology of insulating pull rods and components, applied in the direction of electrical components, contact operating parts, emergency protection devices, etc., can solve problems such as unsatisfactory insulation performance, limit the development trend of switchgear, large and bulky ceramic insulation structure of insulating pull rods, etc., to achieve Novel concept, not easy to fall off, firm and accurate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

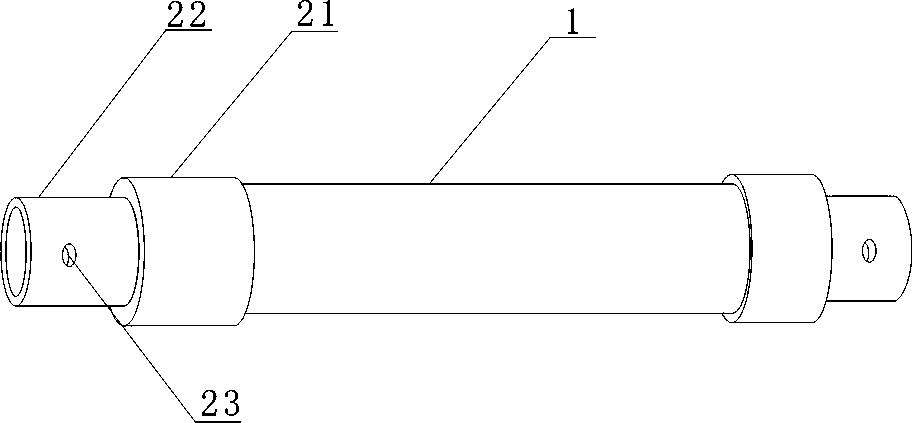

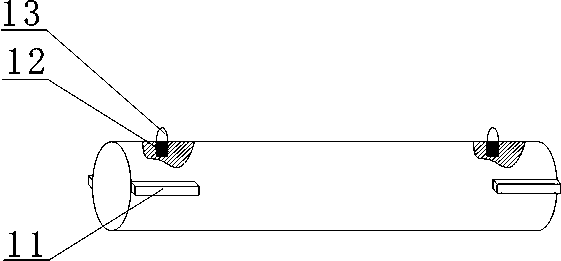

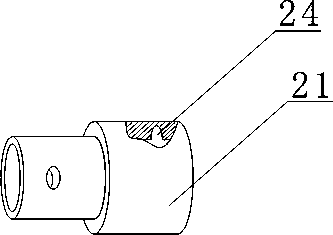

[0023] Such as figure 1 As shown, an insulating tie rod assembly includes an inner joint, an outer joint, and an insulating tie rod 1; two inserts 11 are respectively arranged on the circumferential outer walls of the left and right ends of the insulating tie rod 1, and the two inserts 11 are arranged symmetrically. 1 The upper ends of the outer walls of the left and right ends are respectively provided with installation grooves, and a spring 12 is fixed in the installation groove, and a positioning block 13 is fixedly connected to the upper end of the spring 12; one end of the inner joint is provided with an installation sleeve 21, and the installation sleeve 21 is open at one end The hollow structure of the installation sleeve 21 is provided with two symmetrical slots 25 on the inner side wall of the installation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com