Chain plate type material pre-sorting machine

A pre-sorting, chain plate technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of difficult to meet the sorting needs, low efficiency, short express parcels can not be allocated, etc., to meet the sorting needs, sorting high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

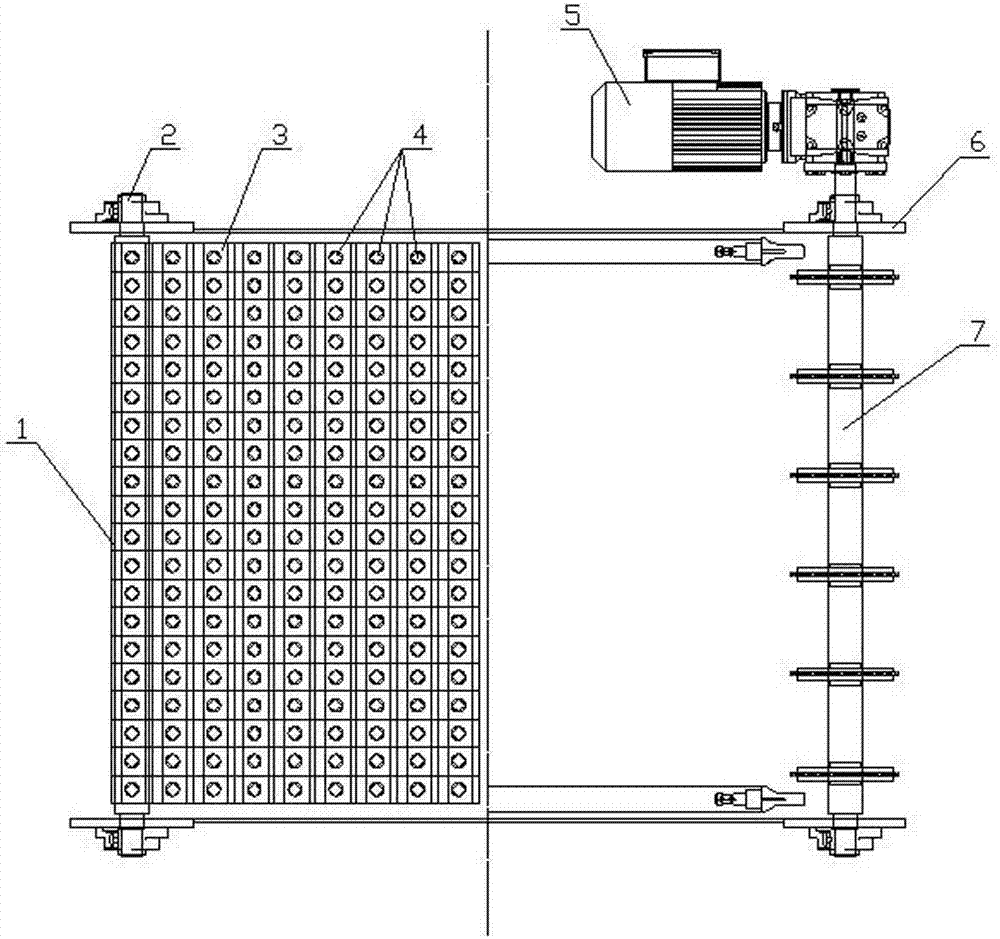

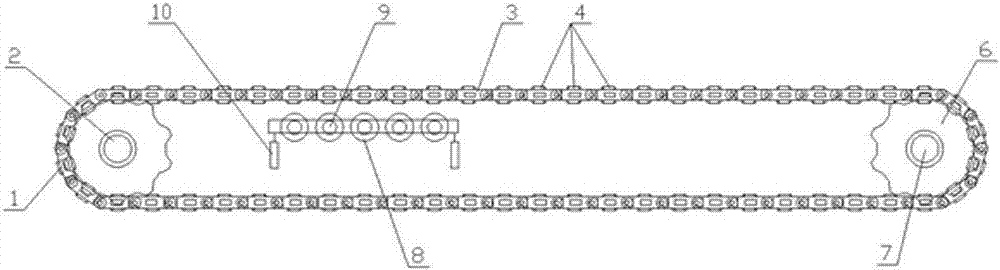

[0012] Such as figure 1 and figure 2 As shown, the chain plate material pre-sorter of the present invention includes a power mechanism 5, a driving shaft 7 and a driven shaft 2, the power mechanism 5 is a motor, and the output shaft of the motor is connected to one end of the driving shaft 7. Both ends of the driving shaft 7 and the driven shaft 2 are fixed with a sprocket 6, and the driving shaft 7 and the driven shaft 2 are covered with a plate type endless chain 1 hinged by a plurality of long strip unit plates 3. Wherein, the gap between adjacent elongated unit plates 3 is 1 mm. Both ends of the elongated unit plate 3 are processed with meshing holes matching the sprocket 6, and the two ends of the elongated unit plate 3 are engaged with the sprockets 6 at the two ends of the driving shaft 7 and the driven shaft 2 by means of the engaging holes. together. Rollers 4 are evenly distributed in the longitudinal direction of the elongated unit boards 3 , and the number of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com