Elastic support rod of cloth expanding mechanism of sewing equipment

A technology of elastic support rods and equipment, which is applied in the direction of cloth feeding mechanism, sewing machine components, sewing equipment, etc., and can solve the problems of excessive adjustment of cloth support force and damage of cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

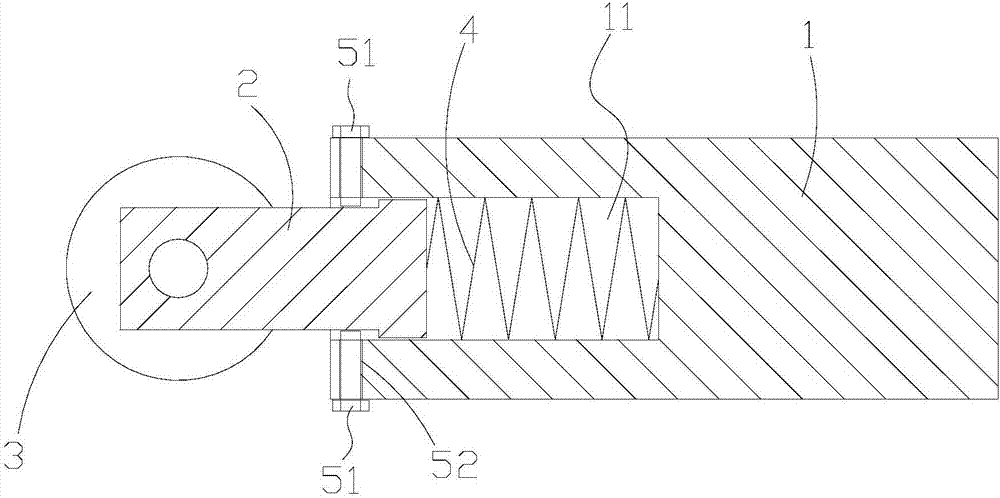

[0019] Embodiment 1: As a preferred setting method of the limit mechanism, the rear end of the bracket 2 is set as a T-shaped stepped structure, and the limit mechanism is set on the base 1 by the first screw rod 51 and connected with the blind The hole 11 is connected with the first threaded hole 52. The first screw 51 is installed in the first threaded hole 52, and the rod body of the first screw 51 and the rear end of the bracket 2 are set as a T-shaped step-shaped structure. The surface is contacted and limited, and this embodiment has the advantages of simple structure and reliable use.

Embodiment 2

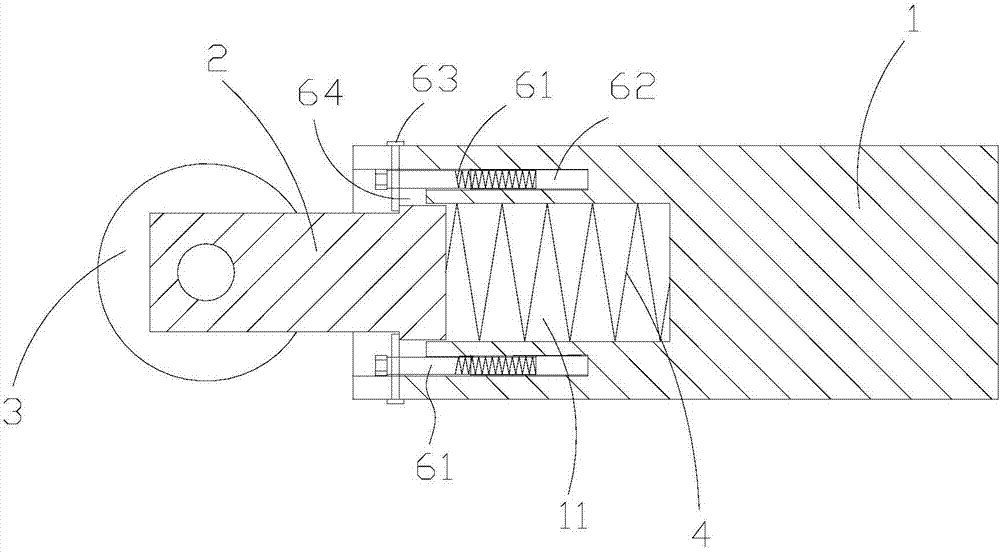

[0020] Embodiment 2: As another preferred setting method of the limit mechanism, the rear end of the bracket 2 is set as a T-shaped stepped structure, and the limit mechanism includes a second screw rod 61 and a screw on both sides of the blind hole 11. The second threaded hole 62, the locking pin 63 and the locking pin slot 64 arranged between the second threaded hole 62 and the blind hole 11, the second screw 61 is installed in the second threaded hole 62, the second The screw 61 is provided with a pin hole for the locking pin 63 to pass through. After the locking pin 63 passes through the pin hole of the second screw 61 and the locking pin groove 64, it is arranged with the rear end of the bracket 2 in a T-shaped stepped shape. The limit surface of the structure is used for contact limit, and this embodiment has the advantage of being able to adjust the elastic force of the spring 4 .

[0021] In practical applications, in order to realize intelligence and achieve higher re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com