Portable high-precision masonry mortar-laying device and working method thereof

A high-precision, convenient technology, applied in the direction of construction, building structure, building materials processing, etc., to achieve the effect of simple structural design, avoiding side overflow of mortar, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

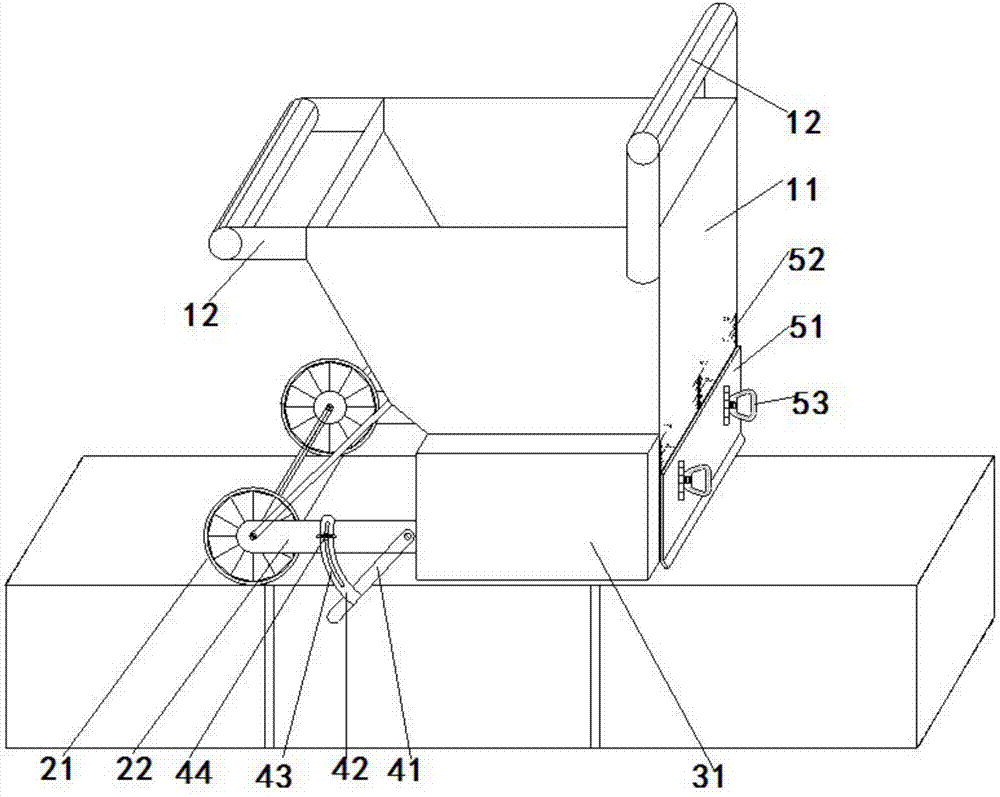

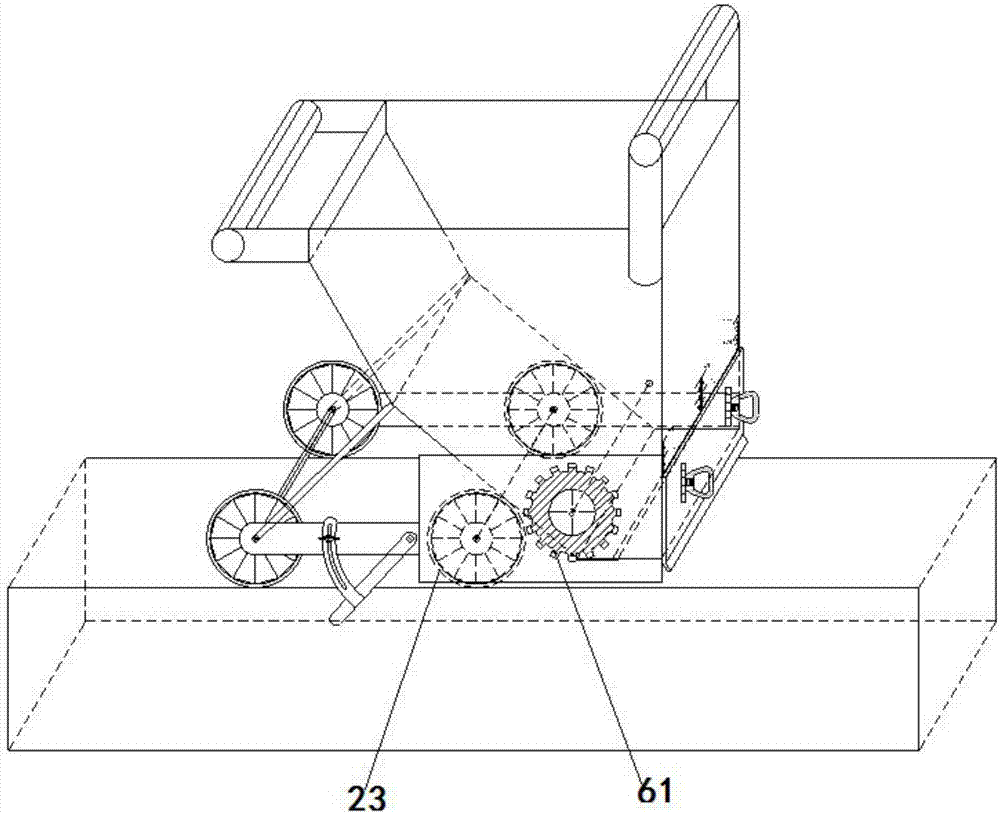

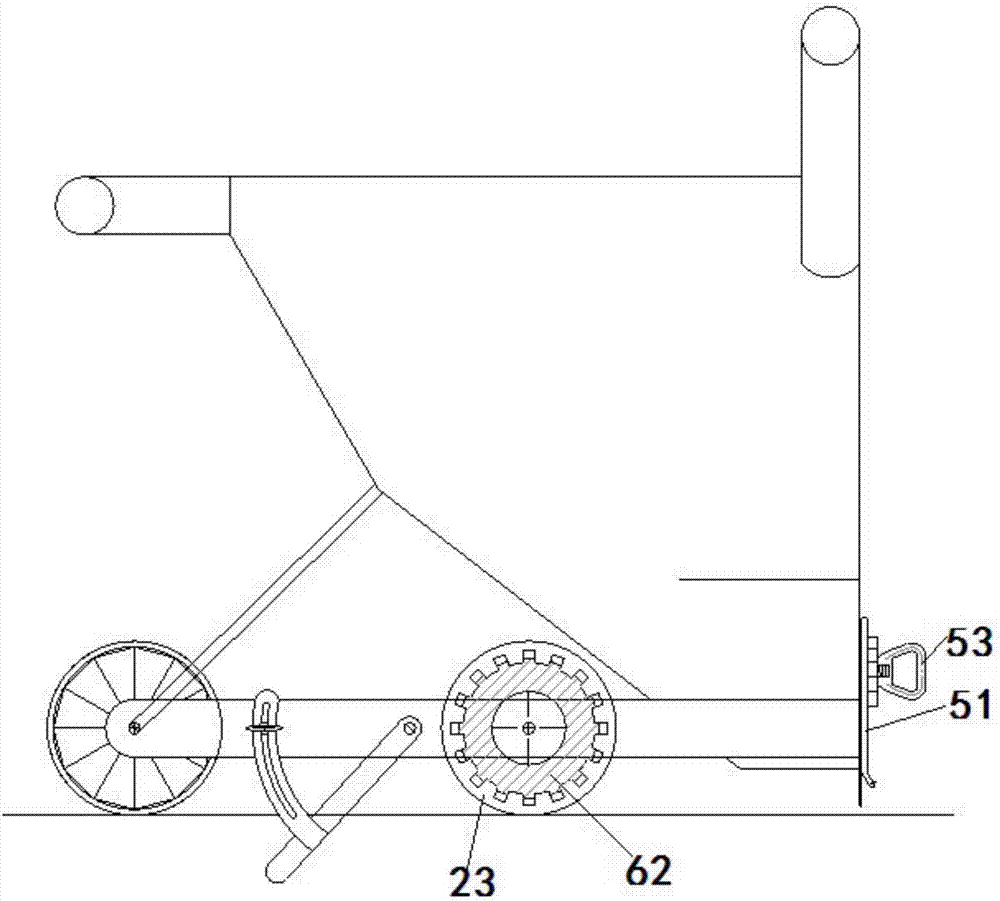

[0035] Such as figure 1 A portable high-precision masonry grouting device shown includes a mortar cylinder 11, and a wheel-type rolling mechanism is distributed at the bottom of the mortar cylinder 11. A calibration mechanism and an autorotation stirring mechanism are respectively provided on the wheel-type rolling mechanism. After the mortar cylinder 11 There is a discharge port at the bottom of the side, and an adjustment mechanism is installed at the discharge port. Two U-shaped handles 12 are installed on the front and top of the mortar cylinder 11. The two U-shaped handles 12 are installed horizontally and vertically, which can meet the requirements of the device at the same time. use and movement of space;

[0036] The wheel-type rolling mechanism includes a front roller 21 and a rear roller 23 fixed on the front and rear ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com