Novel ball collector

A ball collector, a new type of technology, is applied in the direction of non-rotating equipment cleaning, cleaning heat transfer devices, lighting and heating equipment, etc., and can solve the problems of easy formation of dead angles and low ball collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

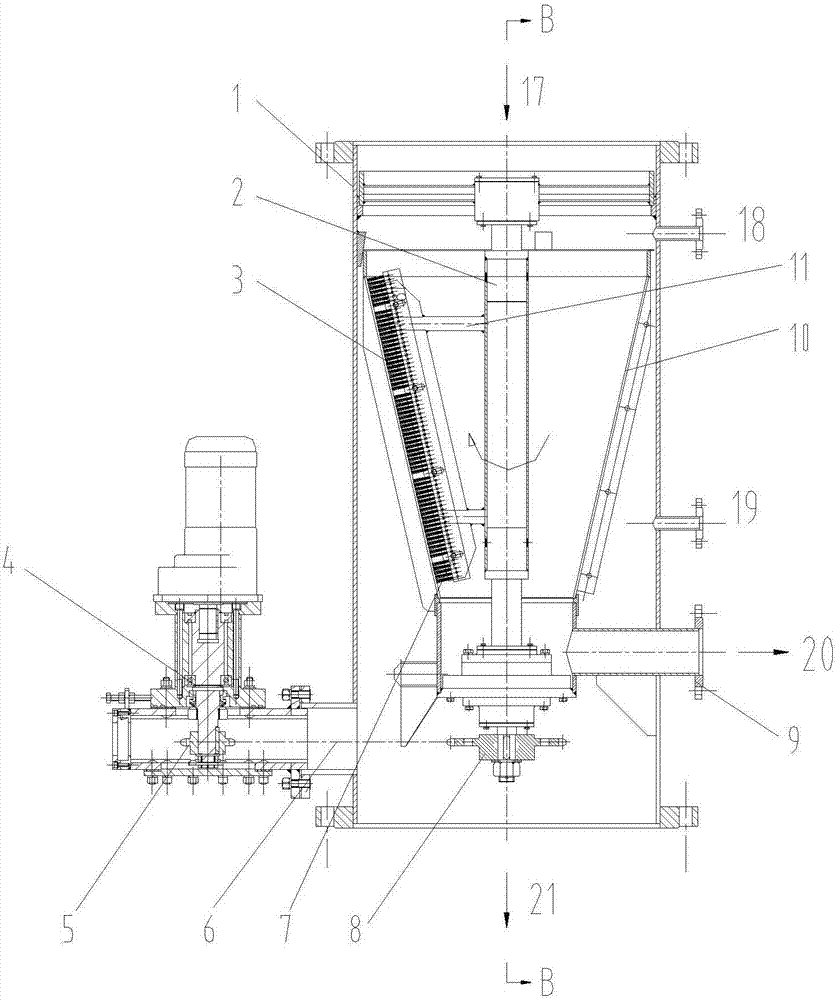

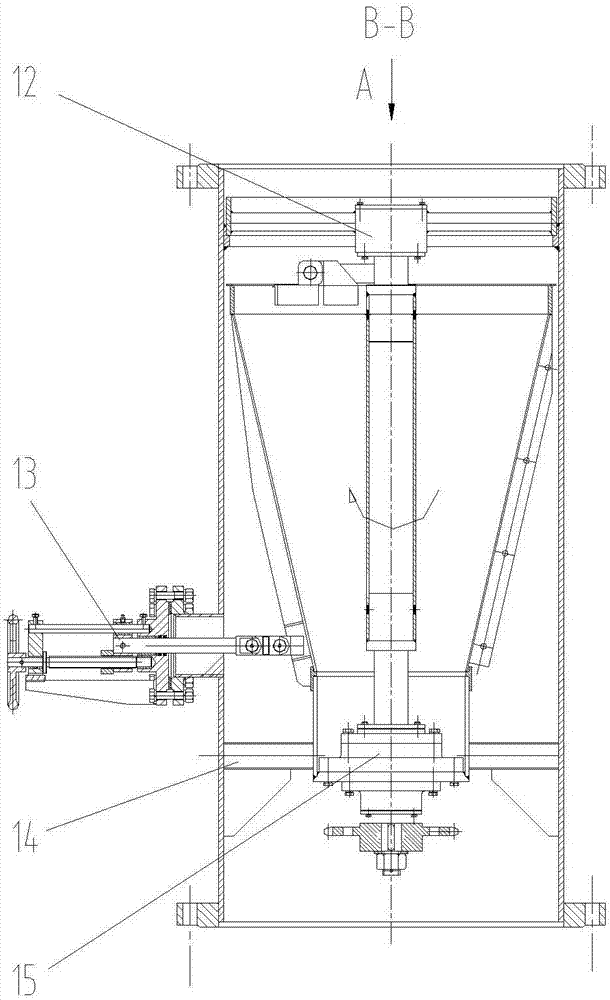

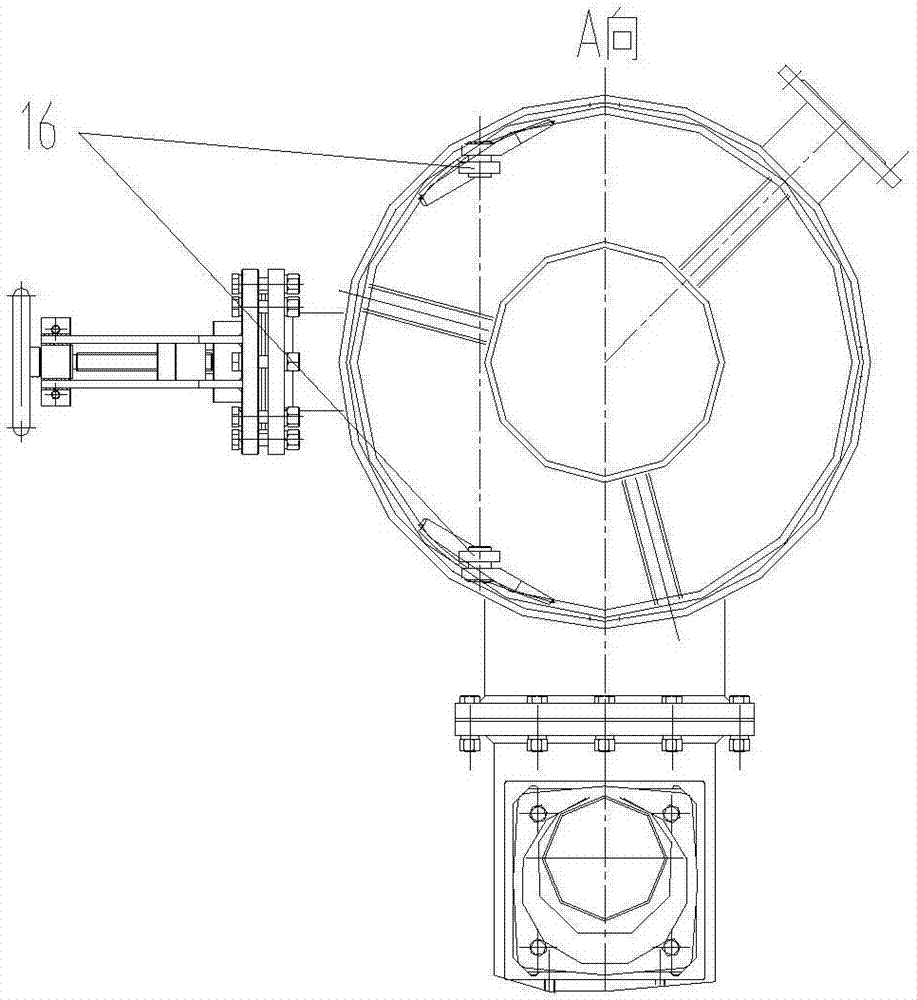

[0029] like Figure 1-3 As shown in the figure, the new ball server includes a ball collection unit, a transmission unit, and a cleaning unit. The ball collection unit includes a fixing device for fixing the cleaning unit. The ball collection unit includes a cylinder 1, a detachable cone The mesh 10 and the cone mesh rotating shaft 2, the detachable cone mesh is arranged in the cylinder, the cone mesh rotation shaft 2 is set in the detachable cone mesh 10, the cleaning unit includes a wire brush 3, the cone mesh The mesh rotating shaft 2 is connected with the transmission unit, and the wire brush is fixed on the cone mesh rotating shaft through a fixing device.

[0030] Relevant parts include: cylinder 1, cone rotating shaft 2, wire brush 3, transmission device 4, small sprocket 5, chain 6, bolt 7, large sprocket 8, ball outlet 9, detachable conical mesh 10 , Wire brush seat 11, upper bearing seat 12, cone net emergency device 13, lower bearing seat support 14, lower bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com