Mine excavator with bucket tooth monitoring function

A technology for excavators and bucket teeth, which is applied in the field of mining excavators and can solve problems such as bucket tooth breakage, collision, and damage to crushing stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

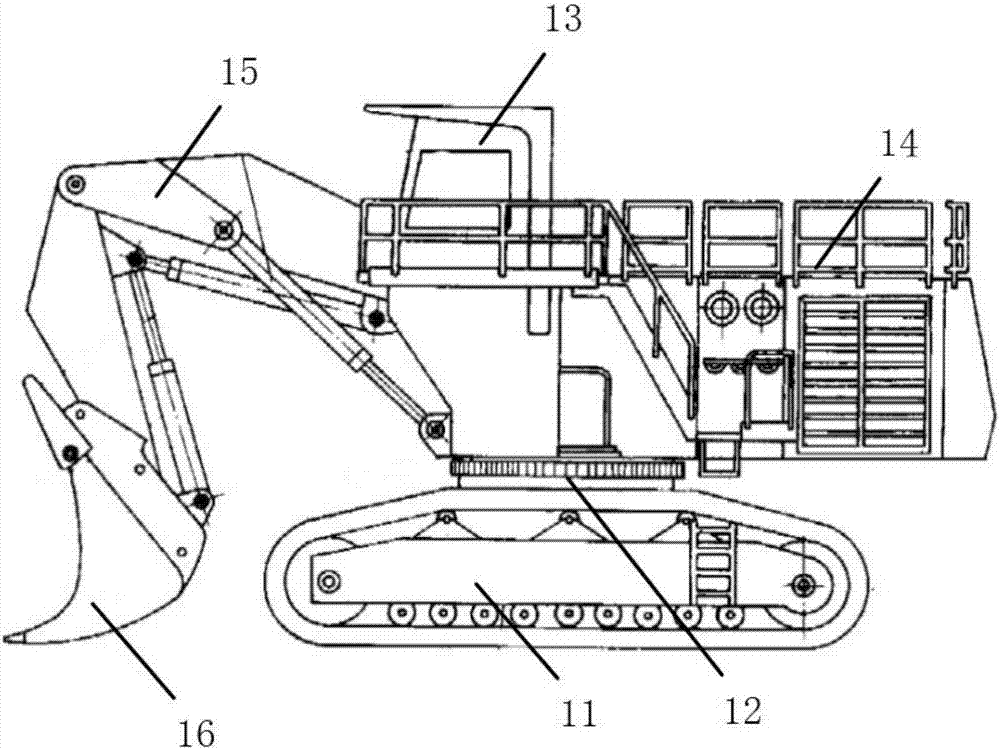

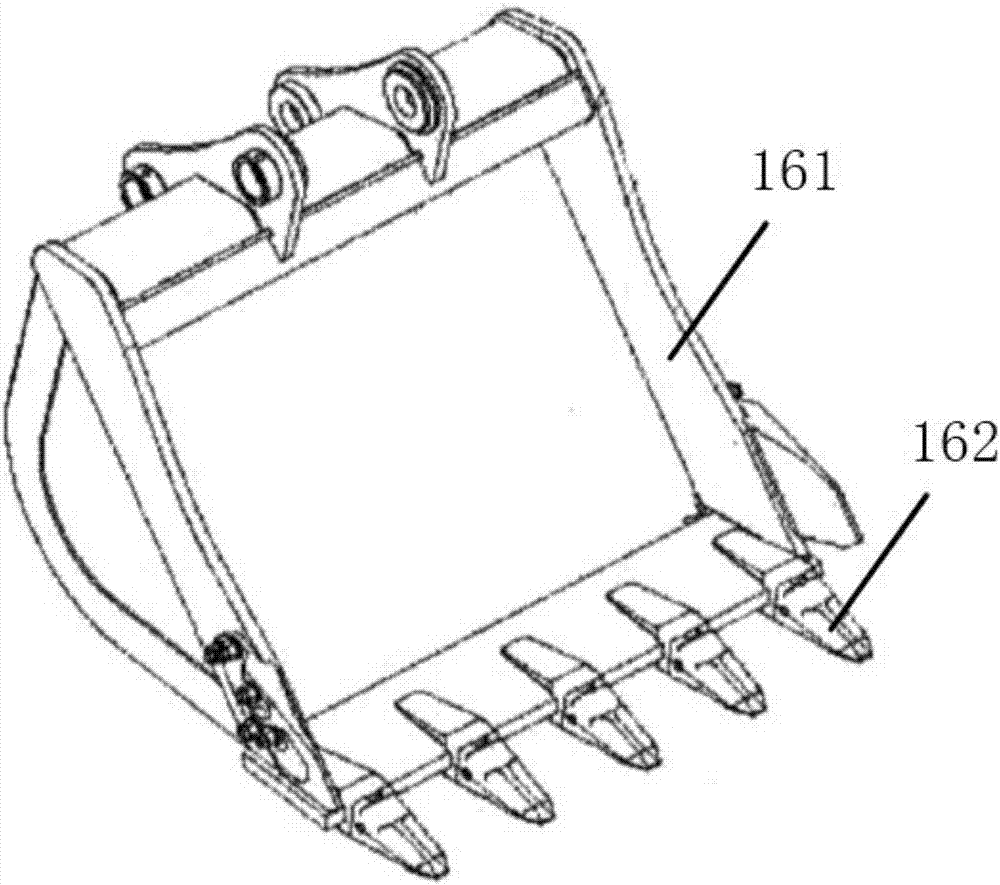

[0047] refer to Figure 1 to Figure 3 , the mining excavator with the monitoring function of bucket teeth 162 provided in this embodiment includes: a chassis 11 and a rotary platform 12, and the rotary platform 12 is provided with a driver's cab 13, an electrical room 14 and a stick 15, and the bucket A bucket 16 is connected to the end of the rod 15; the bucket 16 includes a bucket body 161 and a plurality of bucket teeth 162, the bucket body 161 is connected with the bucket rod 15, and the bucket teeth 162 are connected with the bucket body 161 connection; each of the bucket teeth 162 is provided with a detection device for monitoring the breakage of the bucket teeth 162, the detection device is connected to the monitoring system signal, and the driver's cab 13 is provided with an alarm connected to the monitoring system signal. device.

[0048] The bucket 16 includes a bucket body 161 and bucket teeth 162. A detection device for monitoring the breakage of the bucket teeth ...

Embodiment 2

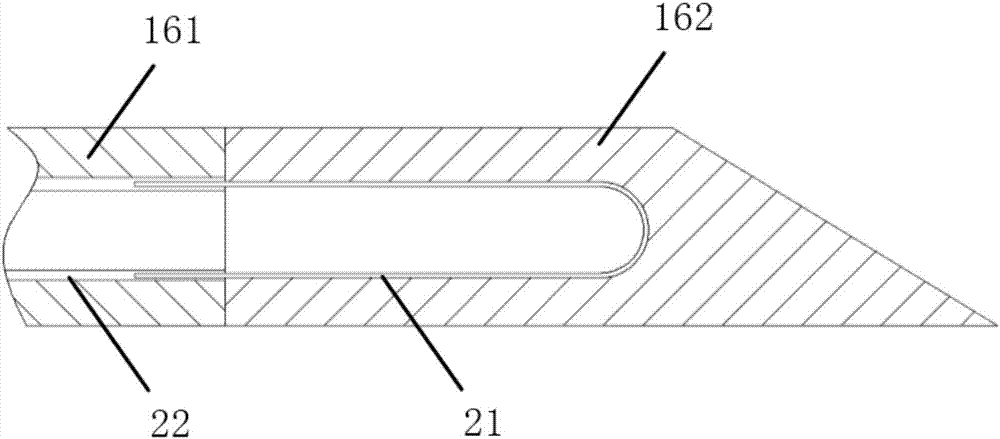

[0054] In the mining excavator with the monitoring function of the bucket teeth 162 provided in this embodiment, the U-shaped conductors 21 in the plurality of the bucket teeth 162 are arranged in parallel.

[0055] Wherein, each U-shaped conductor 21 is independent, so that according to the position of the low-level signal, it is possible to determine which bucket tooth 162 is broken, and to give a reminder.

Embodiment 3

[0057] refer to Figure 4 and Figure 5 , The mining excavator with the monitoring function of the bucket teeth 162 provided in this embodiment further includes an air supply system, and the air outlet of the air supply system is communicated with the electrical room 14 .

[0058] In this embodiment, the monitoring of the state of the bucket teeth 162 is mainly realized by the detection device and the monitoring system connected to the detection device, and depends on the stable operation of the monitoring system. If the monitoring system fails, it will cause an inability to issue an alarm or false alarm, affecting the work. efficiency, and even cause damage to the excavator or the supporting crushing station. However, due to the high power of the mining excavator, the electrical equipment in the electrical room 14 emits a large amount of heat, causing the temperature in the electrical room 14 to rise. When the temperature is high, the electrical equipment may malfunction. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com