Rapid shoe size printing device for leather shoe production

A printing device and shoe size technology, applied in applications, footwear, shoemaking machinery, etc., can solve the problems of large consumption, low printing efficiency, and difficulty in adjustment, and achieve energy saving, high printing efficiency, and firm fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

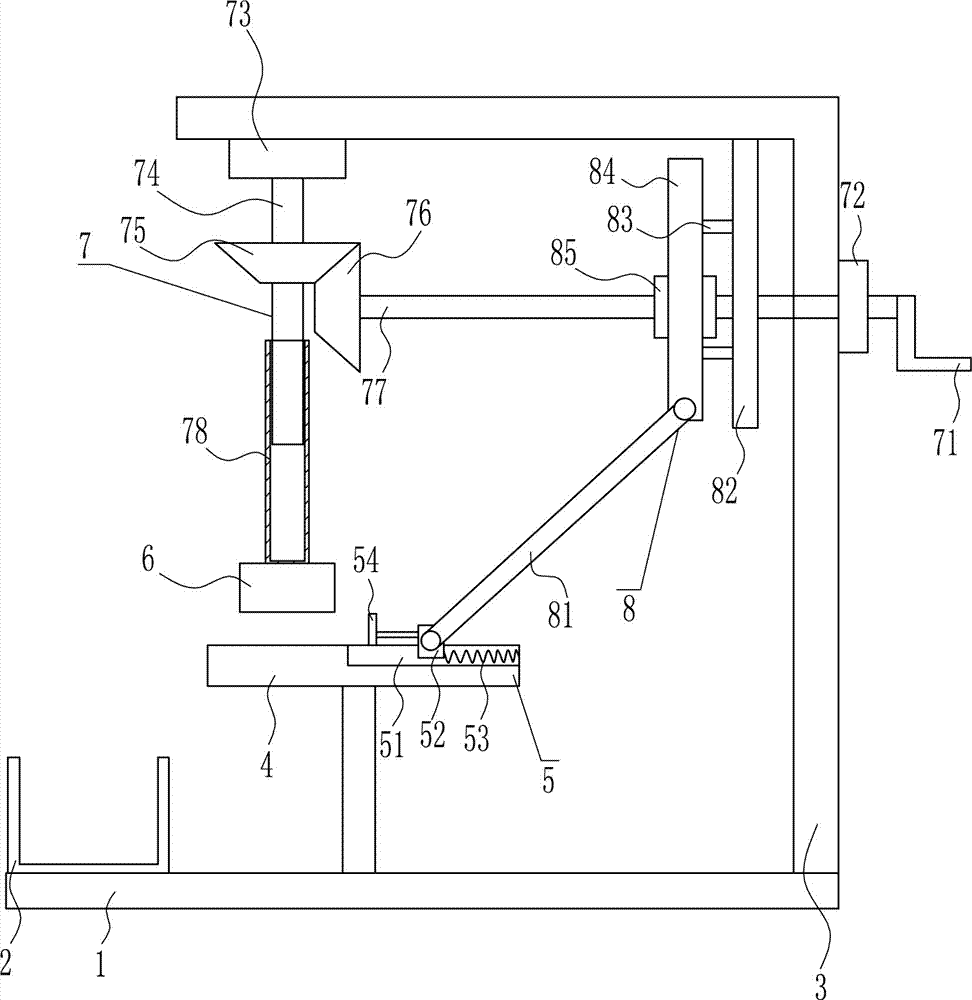

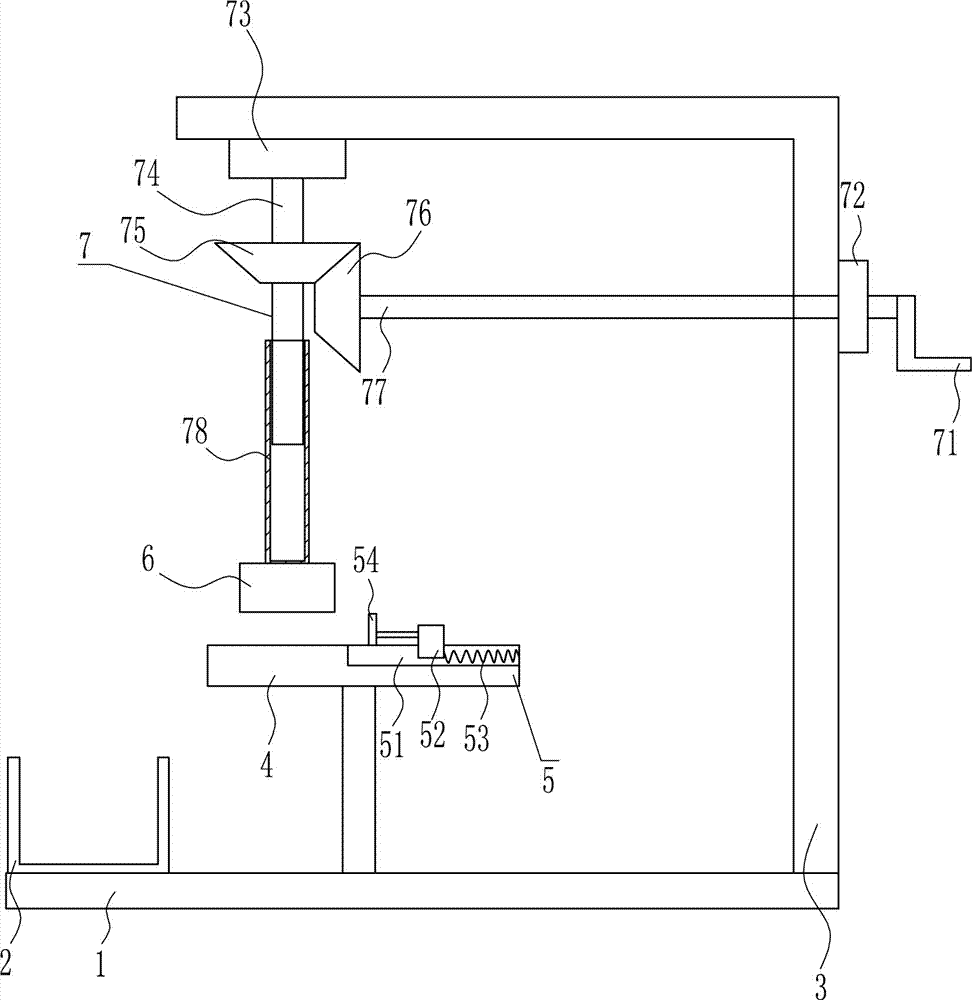

[0035] A shoe size rapid printing device for leather shoe production, such as Figure 1-6 As shown, it includes a bottom plate 1, a collection box 2, a right bracket 3, a placement table 4, a pushing device 5, a coding mold 6 and a driving device 7, and the top of the bottom plate 1 is provided with a collection box 2 and a placement table 4 in turn from left to right. With the right support 3, the right side of the placing platform 4 top is provided with a driving device 5, and the left side of the top of the right support 3 is provided with a driving device 7, and the bottom of the driving device 7 is connected with a coding mold 6.

Embodiment 2

[0037] A shoe size rapid printing device for leather shoe production, such as Figure 1-6 As shown, it includes a bottom plate 1, a collection box 2, a right bracket 3, a placement table 4, a pushing device 5, a coding mold 6 and a driving device 7, and the top of the bottom plate 1 is provided with a collection box 2 and a placement table 4 in turn from left to right. With the right support 3, the right side of the placing platform 4 top is provided with a driving device 5, and the left side of the top of the right support 3 is provided with a driving device 7, and the bottom of the driving device 7 is connected with a coding mold 6.

[0038] Propelling device 5 comprises first slide rail 51, first slide block 52, first spring 53 and push plate 54, and placement table 4 top right side is provided with first slide rail 51, and the slide type on first slide rail 51 is provided with The first slider 52, the left side of the first slider 52 is connected with a push plate 54, the ...

Embodiment 3

[0040] A shoe size rapid printing device for leather shoe production, such as Figure 1-6 As shown, it includes a bottom plate 1, a collection box 2, a right bracket 3, a placement table 4, a pushing device 5, a coding mold 6 and a driving device 7, and the top of the bottom plate 1 is provided with a collection box 2 and a placement table 4 in turn from left to right. With the right support 3, the right side of the placing platform 4 top is provided with a driving device 5, and the left side of the top of the right support 3 is provided with a driving device 7, and the bottom of the driving device 7 is connected with a coding mold 6.

[0041]Propelling device 5 comprises first slide rail 51, first slide block 52, first spring 53 and push plate 54, and placement table 4 top right side is provided with first slide rail 51, and the slide type on first slide rail 51 is provided with The first slider 52, the left side of the first slider 52 is connected with a push plate 54, the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap