Snap spring feeding device

A technology of feeding device and circlip, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting installation speed, high labor intensity, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

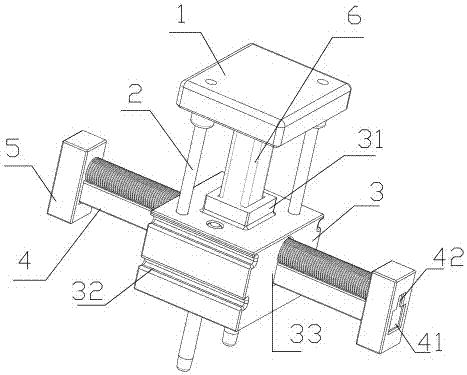

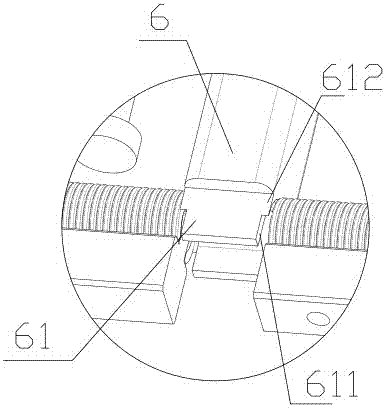

[0035] Example 1, such as figure 1 and figure 2 As shown, a circlip feeding device includes a fixed clip 4, and also includes a lower pressure member 6 and a heel block 5 that is slidably connected with the fixed frame 4; a plurality of circlips are arranged on the fixed clip 4, and the heel block 5 is used for Drive the circlip to move in the direction of the downward pressing member 6, and the lower pressing member 6 includes a pressure head 61 for pressing the circlip from the fixing clip 4, and the pressure head 61 includes an inlet 611 and a resisting patch located above the inlet 611 612 , the entrance 611 is further away from the direction of the heel block 5 than the interference patch 612 .

[0036] The jig 3 is also included, and the side end of the jig 3 is provided with a side opening 33 for connecting the fixing clip 4 , and a passage opening for the lower pressing member 6 to pass through is opened in the vertical direction. Both sides of the jig 3 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com