A vertical arrangement electronic ticket processing equipment

A technology for processing equipment and electronic tickets, applied in the direction of conveyor objects, winding strips, sending objects, etc., can solve the problems of complex equipment structure, high technical difficulty, high cost, etc., achieve good half-folding effect, avoid sharp bends, and half-folding process natural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

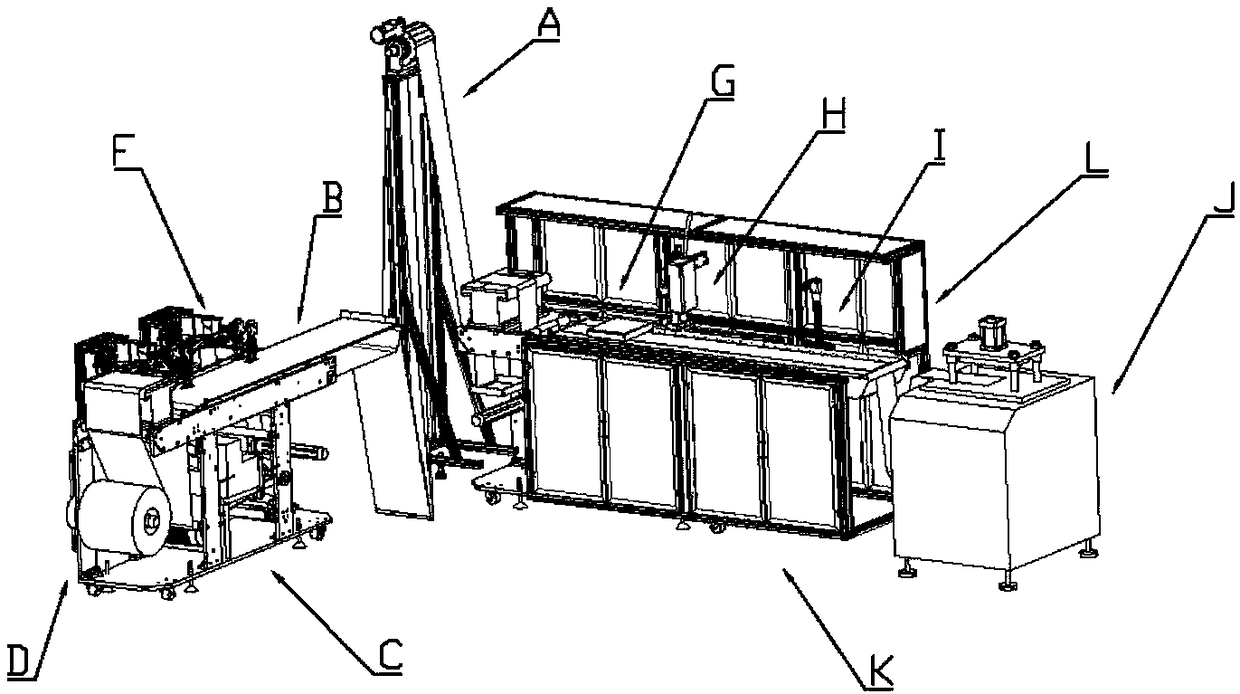

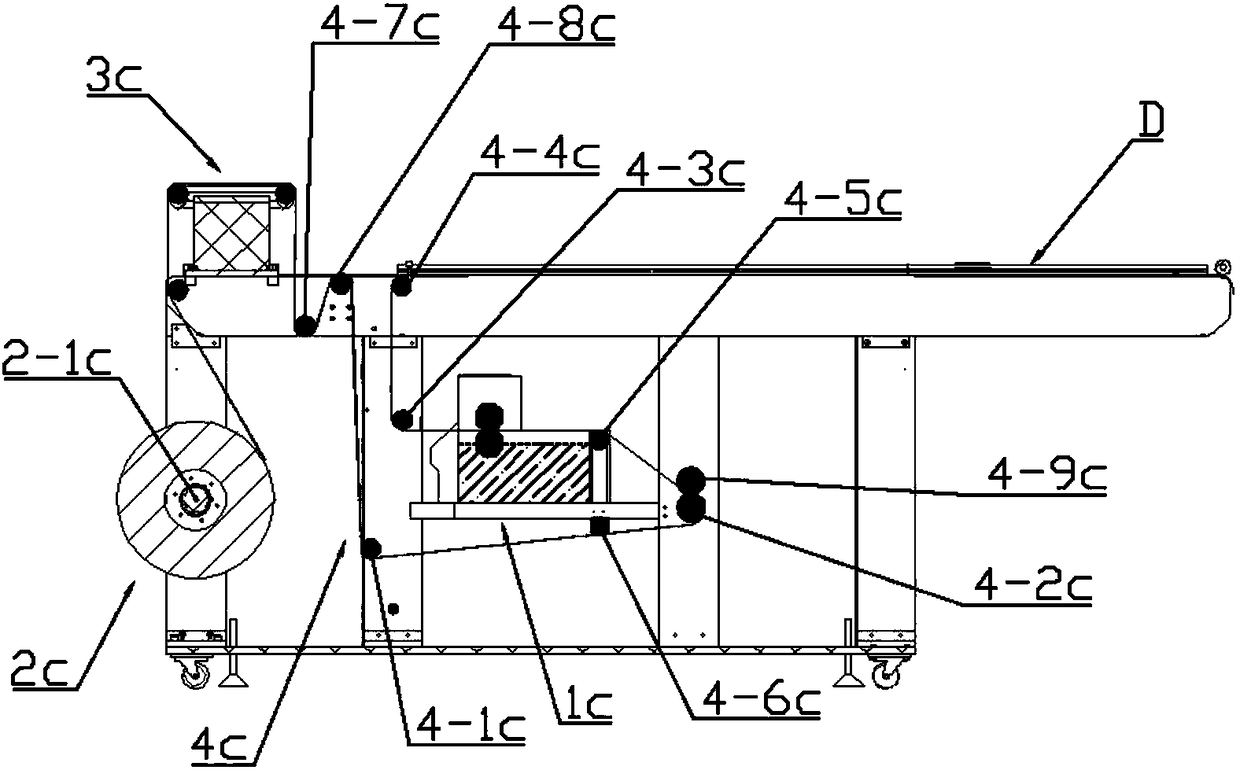

[0045] see Figure 1-Figure 19 , the vertically arranged electronic ticket processing equipment of the present invention comprises a front section processing equipment, a back section processing equipment, a paper tape folding device A arranged between the front section processing equipment and the back section processing equipment, and a die-cutting device connected with the back section processing equipment Apparatus J, wherein, the front-end processing equipment includes a paper rack D, a gluing module C arranged on the paper rack D, an electronic label handling module F, and an electronic label storage module E; the back-end processing equipment includes The rear frame K, the information writing module G, the inkjet module H and the image recognition module I arranged on the rear frame K;

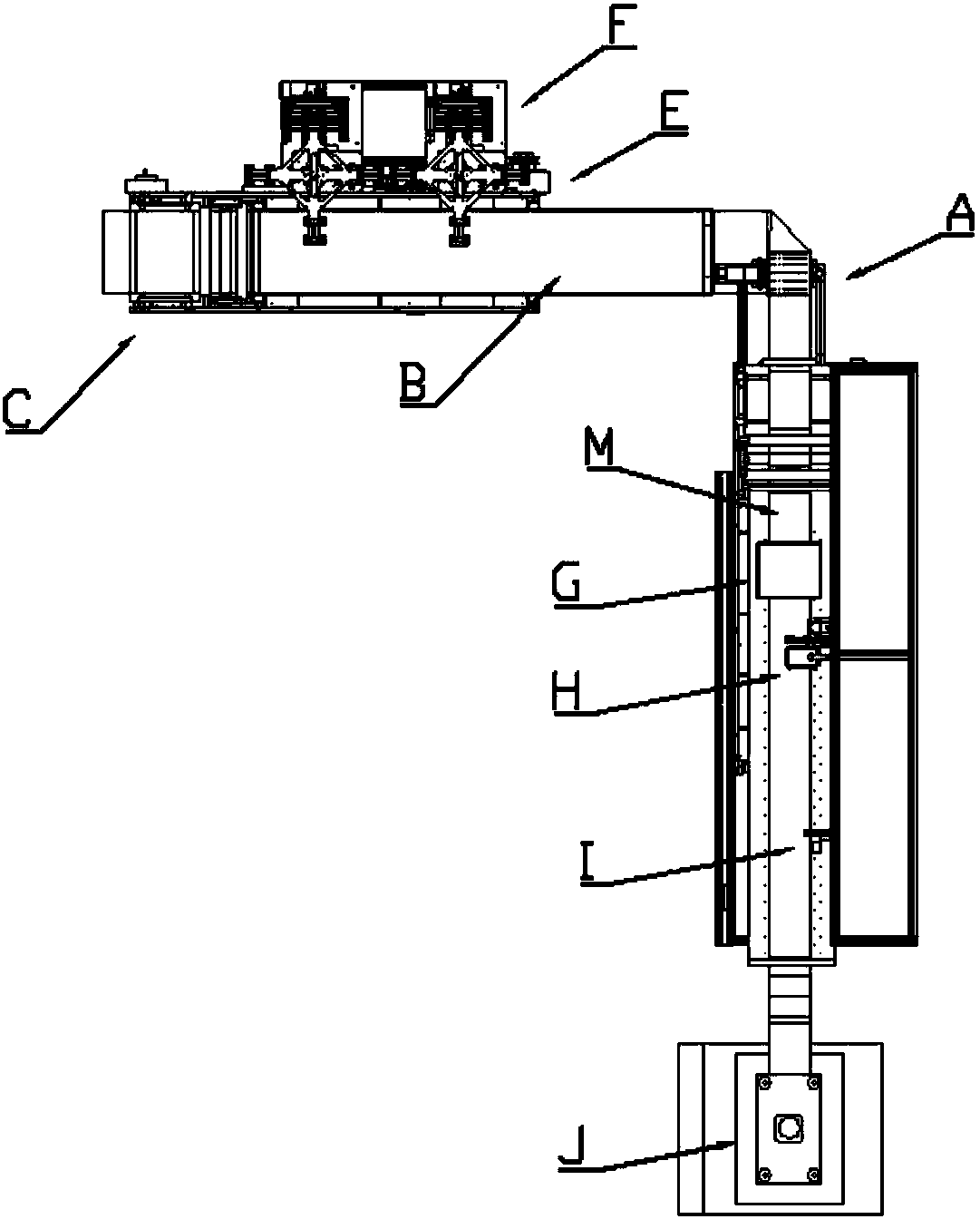

[0046] see figure 1 with figure 2 , the paper tape half-folding device A includes a front-stage paper tape conveying mechanism B arranged on the front-stage processing equipment, a r...

Embodiment 2

[0105] see Figure 22 with Figure 23 The difference between this embodiment and Embodiment 1 is that the paper tape half-folding device A also includes an auxiliary half-folding mechanism 7a, and the auxiliary half-folding mechanism 7a includes a mounting plate 5a, a paper tape guiding mechanism 6a arranged on the mounting plate 5a and Clamping mechanism 4a, wherein, described mounting plate 5a is fixed on the support frame 3a, and described clamping mechanism 4a is arranged on the top of paper tape guiding mechanism 6a; Described paper tape guiding mechanism 6a comprises two groups of mounting plates 5a There are guide assemblies symmetrically distributed on the top, wherein each set of guide assemblies includes a guide shaft 6-1a and a plurality of guide wheels 6-2a mounted on the guide shaft 6-1a through a rotating structure, and the guide shaft 6-1a faces away from The vertical bisector of the mounting plate 5a is inclined outward, and the paper tape is located in the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com