A connection shaft disk and a method for using it to carry out cable hoisting arch bridge construction

A cable hoisting and connecting shaft technology, which is applied in the direction of arch bridges, erection/assembly bridges, bridges, etc., can solve the problems of forced closing, instability, and closing failure, and achieve the effect of preventing forced closing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

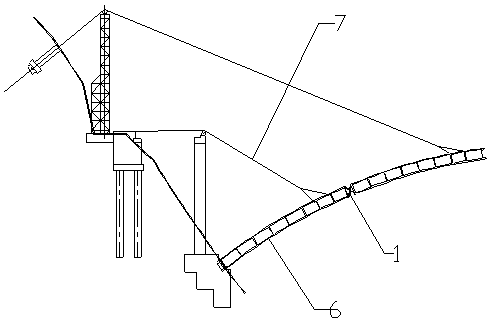

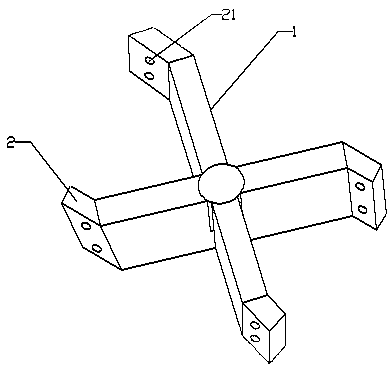

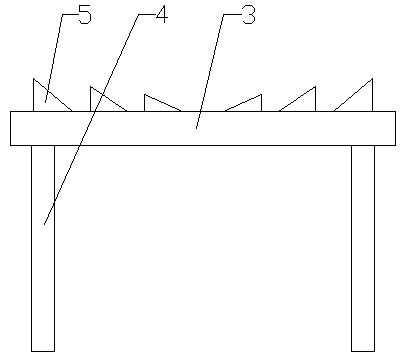

[0024] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 7 As shown, the connecting shaft plate used for the construction of the cable hoisted arch bridge includes two support plates 1 and two steel backing plates 3, the two support plates 1 are hinged together in the middle, and the two ends of each support plate 1 are integrated Bending a support foot 2, the bending direction of the two support feet 2 is opposite, the angle between the support foot 2 and the support plate 1 is between 90-180°, preferably 120-150°, each support foot There are two through holes-21 on the 2; four steel bars 4 are welded on the four corners of the steel backing plate 3, and the steel bar 4 is preferably made of fine-rolled rebar, and the front of the steel backing plate 3 is welded with six parallel bars. Feet 5, these feet 5 all have a slope, these feet 5 are in groups of three, two groups of feet 5 are symmetrically distributed, the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com