Faucet assembly with aerator cartridge and method for mounting the assembly

A technology of faucet assembly and bubbler, which is applied in the direction of pipes/pipe joints/fittings, indoor sanitary pipeline devices, passing components, etc., and can solve problems such as unresolved, adding bubbler sleeves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

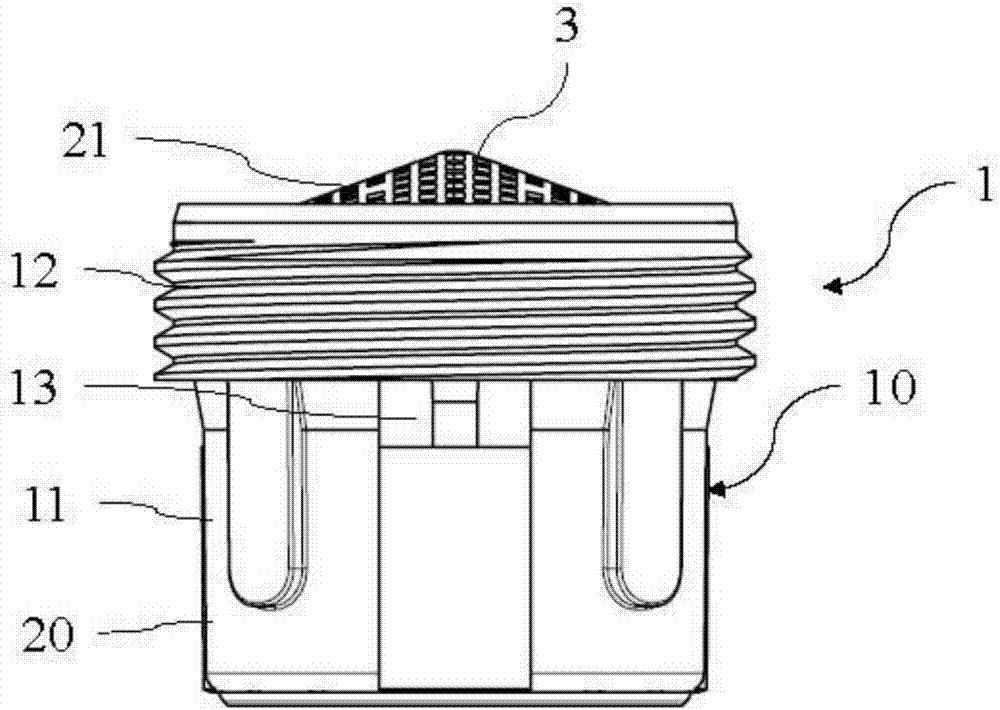

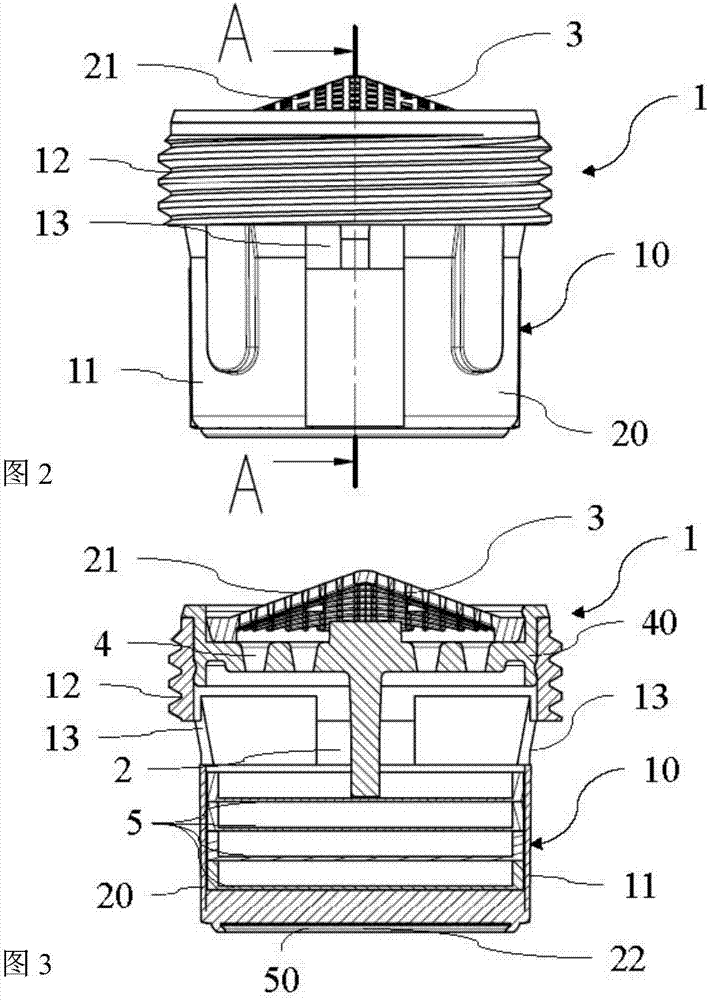

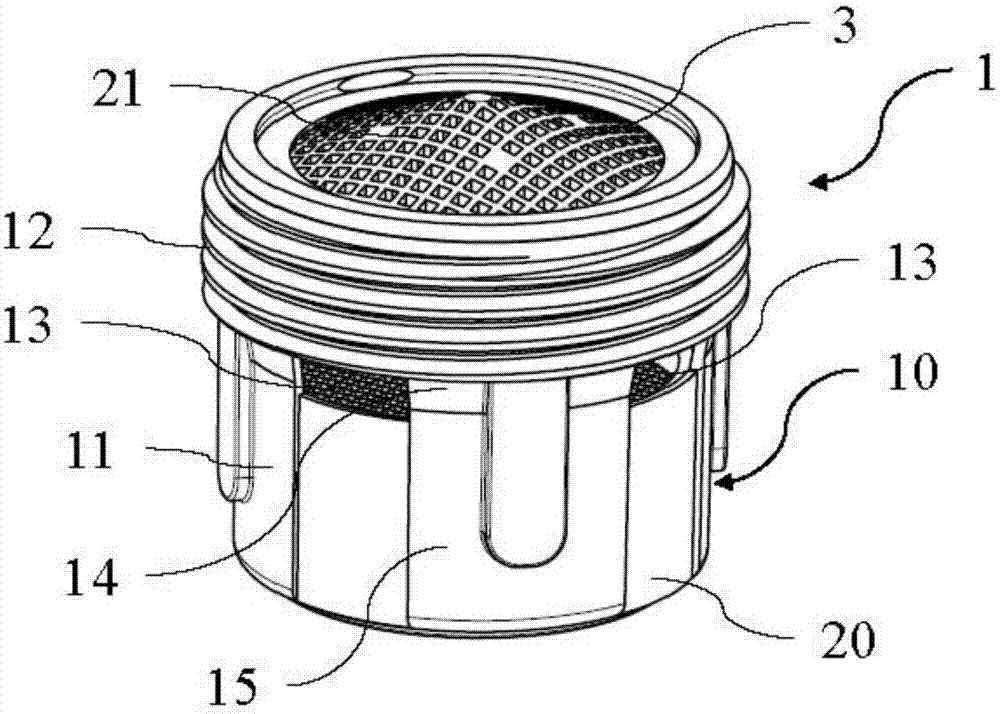

[0068] Reference attached Figure 1-5 , Where the reference numeral 1 generally represents the first embodiment of the bubbler sleeve.

[0069] On the other hand, the reference symbol 1'represents Image 6 The second embodiment of the bubbler sleeve is shown, and the reference numeral 1" represents the Figure 7 The example shown in the bubbler sleeve is not part of the present invention. In the last two figures, the bubbler sleeve shown is housed in an operating position inside the termination channel of the tap, below which termination channel is indicated as port 100.

[0070] Figure 8 with Picture 9 Finally, two variants of the bubbler sleeve 1 according to the first embodiment are shown, which are provided with special protrusions for manually unscrewing the bubbler sleeve.

[0071] The present invention relates to a faucet assembly, which includes one of bubbler sleeves 1, 1'. The faucet assembly includes a base part, which is not shown in the drawings because it is known pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com