Non-woven fabric scrap opening recycling system and recycling method

A recycling system and leftover technology, applied in the field of textile machinery and equipment, can solve problems such as recycling of leftover waste manufacturers, poor working environment at the recycling site, and impact on the quality of recycled products, so as to avoid leakage and pollution, reduce production costs and operations The effect of labor intensity, concentration and efficient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

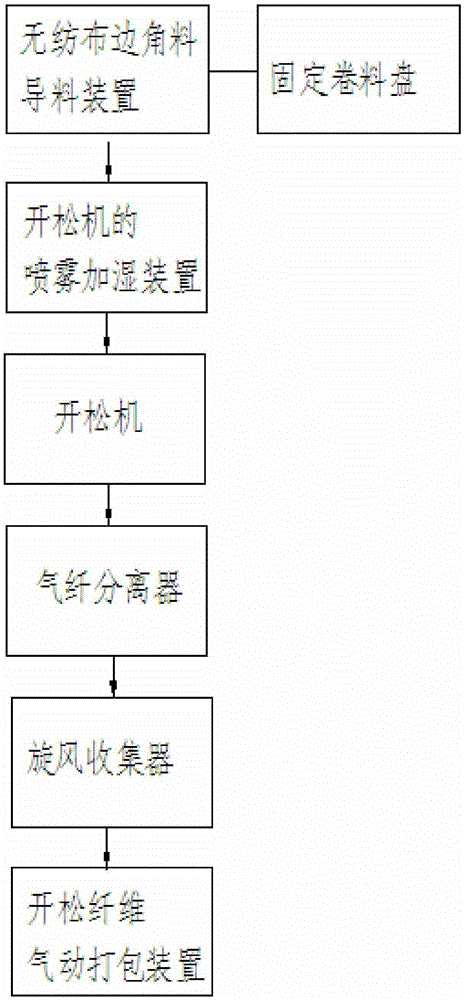

[0029] combine figure 1 , a non-woven fabric scrap opening recovery system, comprising a non-woven fabric scrap guide device, a spray humidification device for an opener, an opener, and a pneumatic packaging device for opening fibers, and the non-woven fabric scrap guide device There is a non-woven fabric leftover roll tray connected, and the spray humidification device of the opener is arranged between the non-woven fabric leftover material guide device and the opener, and the discharge end of the opener is collected by an air fiber separator and a cyclone. The feed port of the cyclone collector is connected to the feed port of the cyclone collector, and the discharge port of the cyclone collector is connected to the pneumatic packing device for opening fibers.

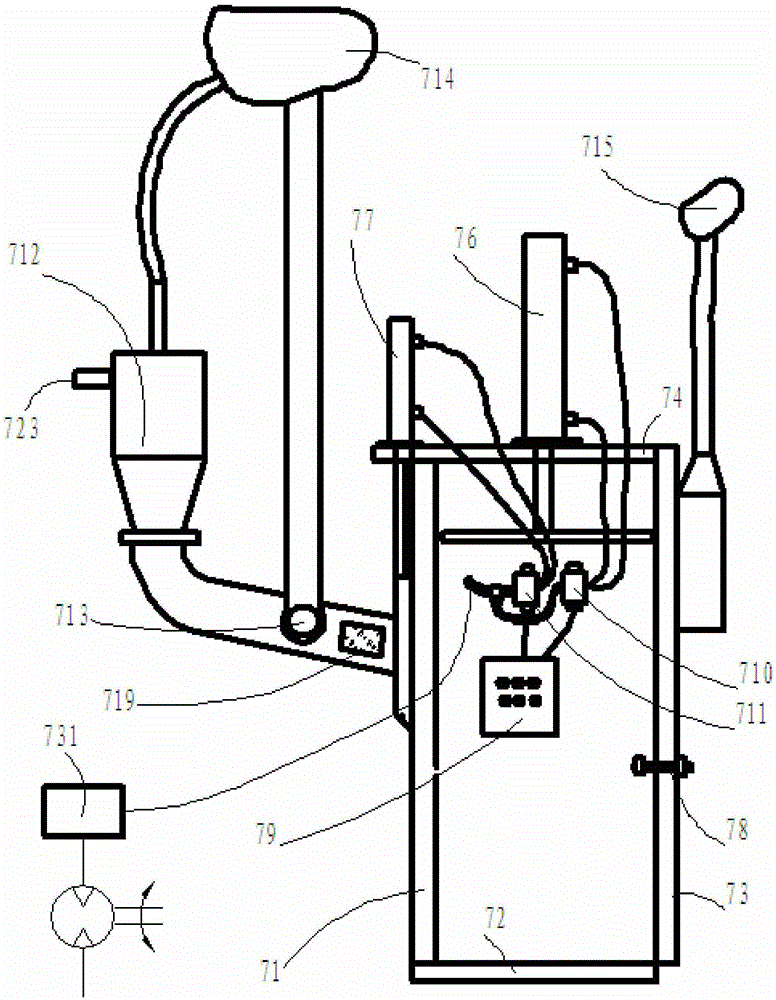

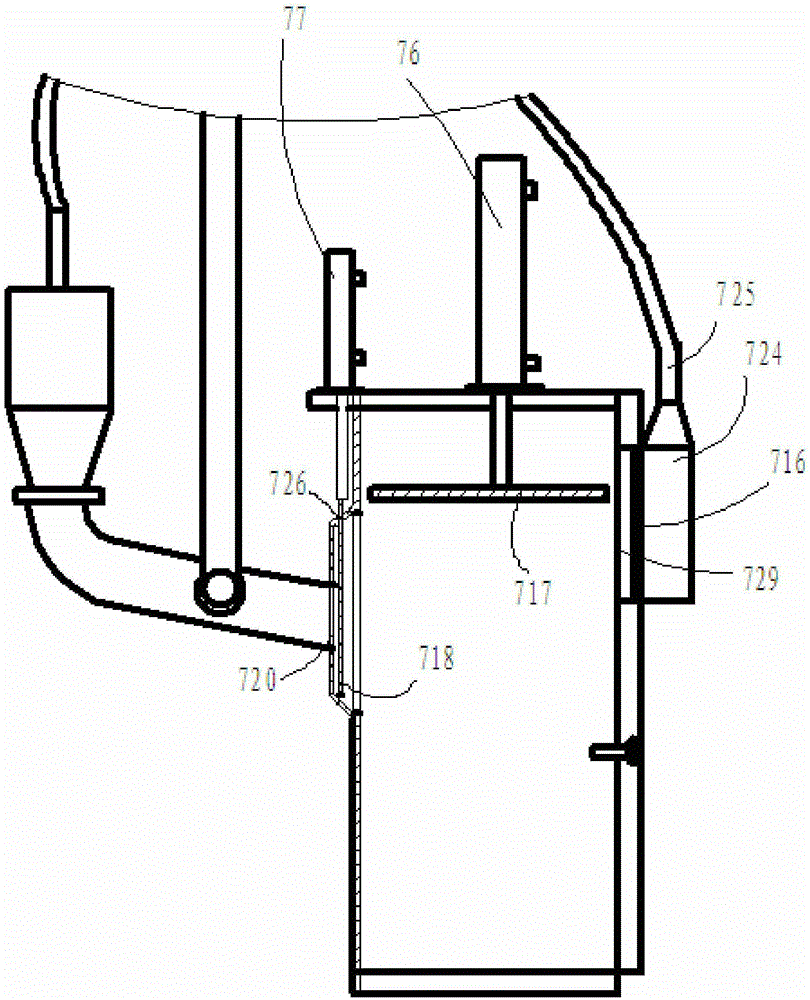

[0030] Such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com