Quick connector of pull-out faucet and quick-connection pull-out faucet structure

A faucet and fast technology, applied in the direction of pipes/pipe joints/fittings, hose connection devices, connections with fluid cut-off devices, etc., it can solve the problems of dripping, difficult tightening, and poor reset of the joint, and prevent water from flowing back. And dripping, smooth pulling and reset, good reset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

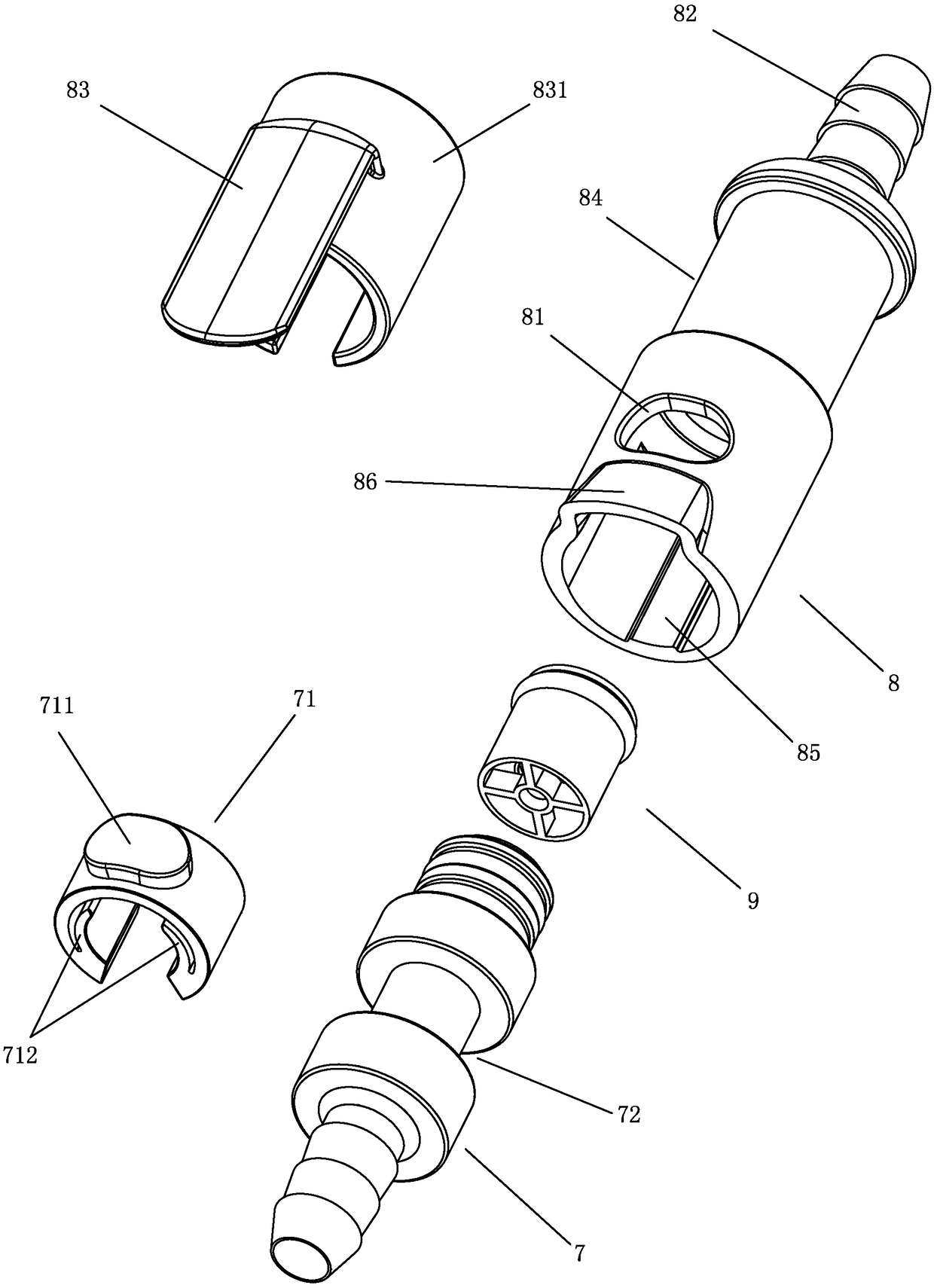

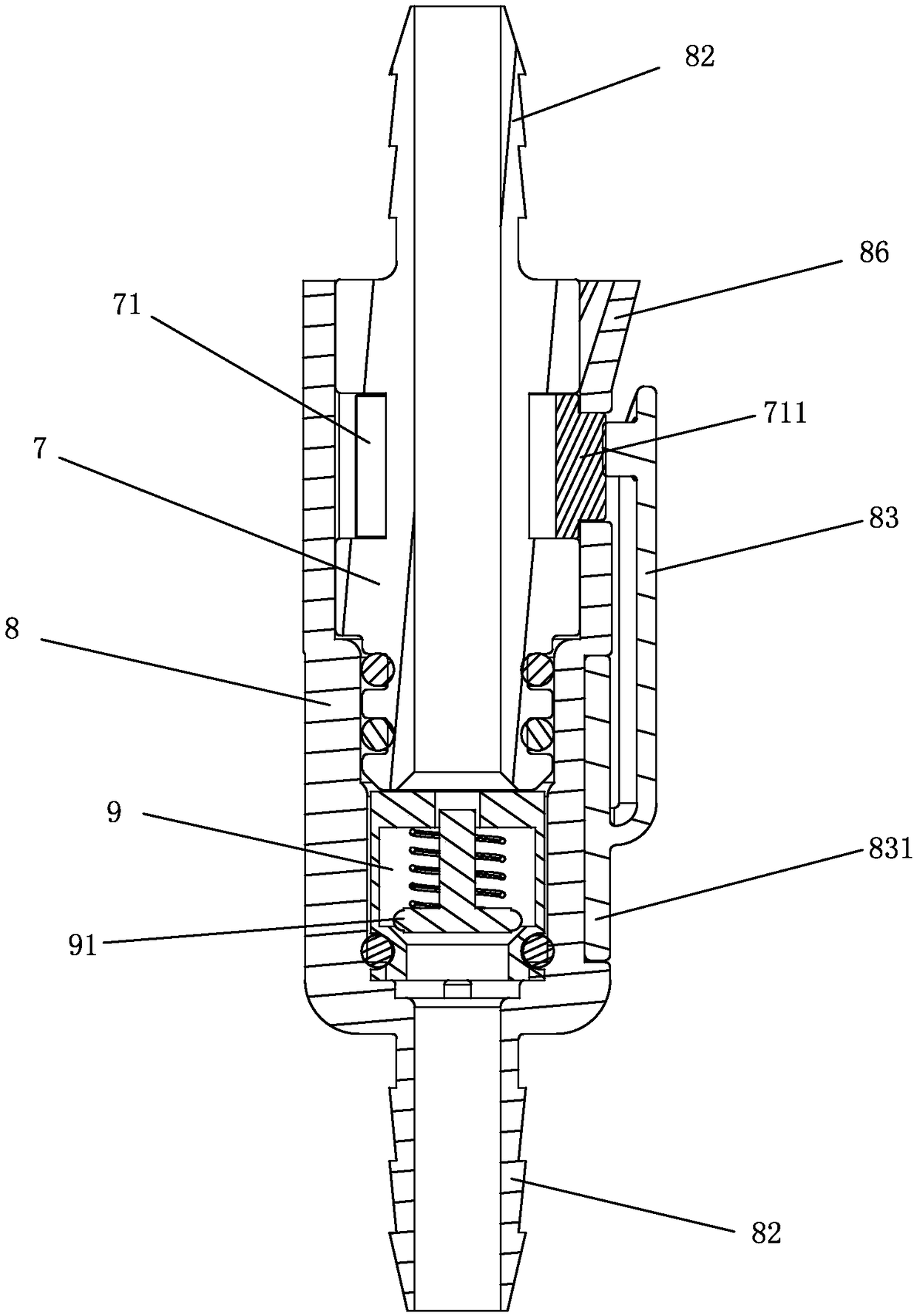

[0024] refer to figure 1 and figure 2 , a quick connector for a pull-out faucet of the present invention, including a male connector 7 for connecting the hose of the pull-out faucet and a female connector 8 for sealing and inserting the water inlet pipe, the female connector 8 is a pipe that matches the male connector 7 type structure, and also includes a check valve 9 located in the female joint 8 and connected to the end of the male joint 7 and connected to the water channel. The outer wall of the male joint 7 is provided with an elastic positioning clip 71, and the elastic positioning clip 71 protrudes with a locking protrusion 711 , the female joint 8 is provided with a positioning card hole 81 matching through the locking protrusion 711, the check valve 9 is a cylindrical structure and the outer wall is sealed against the inner wall of the female joint 8, and the two ends of the check valve 9 are respectively provided with water inlets and In the water outlet hole, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com