Method for carrying out neutron measurement on uranium contents in uranium-containing liquid and achievement device of method

A uranium content and neutron detector technology, applied in the field of nuclear detection/nuclear analysis, can solve the problems of inability to carry out online monitoring of nuclear criticality safety, long analysis process, cumbersome operation, etc., and achieve short measurement time, high analysis accuracy, and responsive fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for neutronically measuring uranium content in uranium-containing liquids, comprising:

[0034] pass 241 The neutrons emitted by the Am-Be neutron source (average neutron energy 5.0MeV) penetrate the pipe wall and undergo fission reaction with the uranium-containing liquid in the pipe. The neutron count rate N in the pipe is measured by the neutron detector 测 , according to the calculation model N 测 = Φ 热 σ f N U-235 ty, calculate the uranium content N in the pipeline U-235 .

[0035] In the present invention Φ 热 is the average neutron fluence rate in the pipeline, the average neutron fluence rate Φ in the pipeline 热 The calculation method is as follows:

[0036] (1) Inject uranium-containing liquids with different uranium contents of 100mg / L, 500mg / L, 1000mg / L, 2000mg / L, and 5000mg / L into the pipeline respectively, and measure N at corresponding concentrations by neutron detectors 测 ,

[0037] (2) According to the calculation model N 测 = Φ 热 σ f N...

Embodiment 2

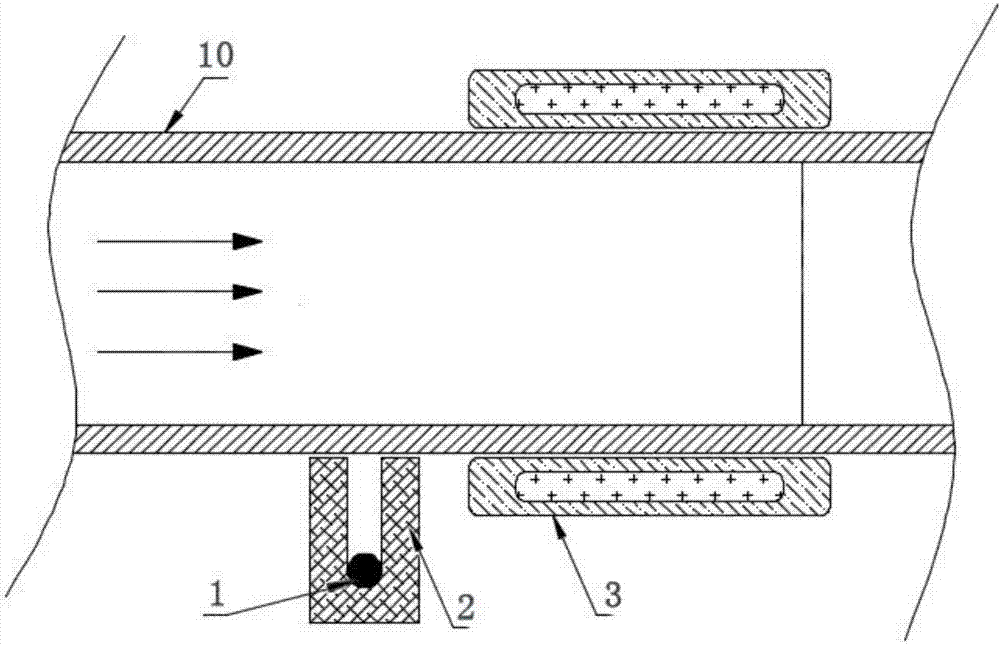

[0049] This embodiment provides a device for realizing the method of neutron measurement of uranium content in uranium-containing liquid, and the specific settings are as follows figure 1 As shown, it includes a neutron source 1 installed on the uranium-containing liquid pipeline 10, a neutron detector 3 arranged on the uranium-containing liquid pipeline 10, connected with the neutron detector 3 and based on the calculation model N 测 = Φ 热 σ f N U ty, calculate the uranium content N in the pipeline U The signal processing device, where, N 测 is the neutron count rate detected by the neutron detector 3, Φ 热 is the average neutron fluence rate in the pipeline, σ f is the microscopic section, t is the measurement time, and y is the average number of neutrons released per fission.

[0050] The present invention can directly arrange the neutron source 1, the neutron detector 3 and the signal processing device on the pipeline (point) to be monitored, so that the quantitative de...

Embodiment 3

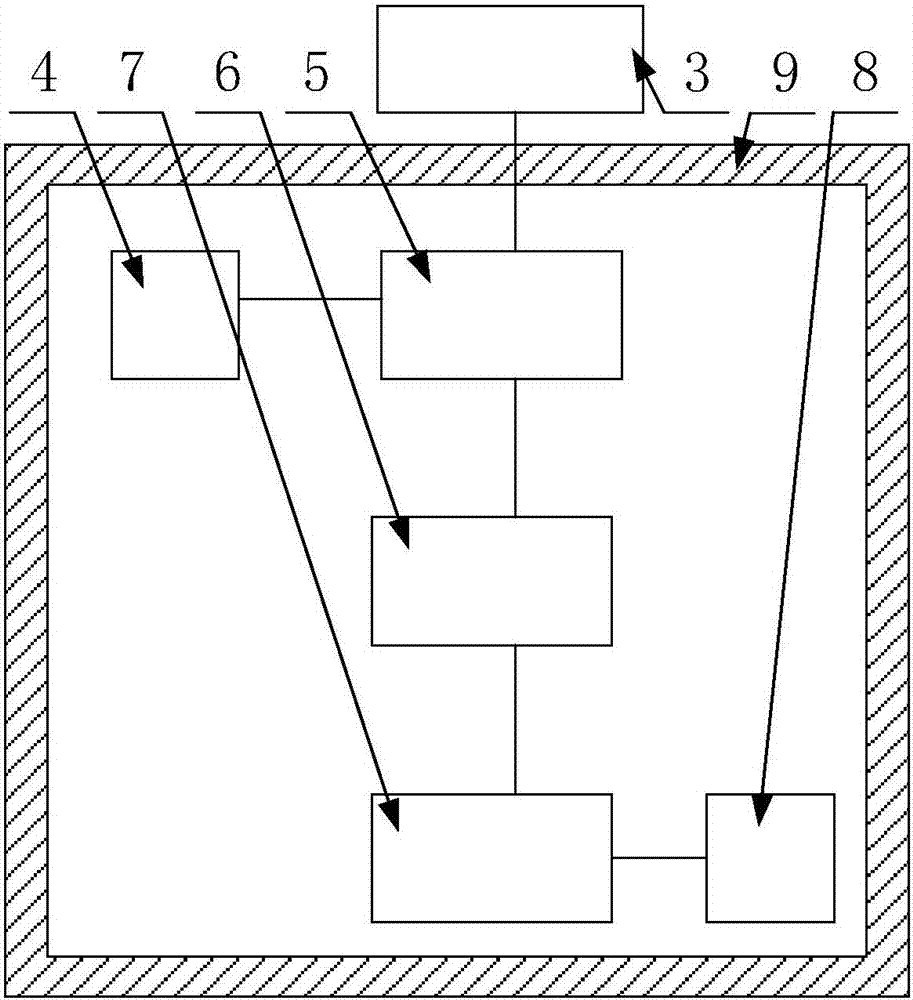

[0052] The only difference between this embodiment and Embodiment 2 is that this embodiment provides a specific structure of a signal processing device, such as figure 2 Shown; Simultaneously, present embodiment has also increased electronics circuit shielding body 9 and neutron source shielding body 2 on the basis of embodiment 2, as figure 1 shown.

[0053] In the present embodiment, the signal processing device includes a preamplifier 5, an amplifier 6, a discrimination counter 7, and a data processing terminal 8 connected in sequence; the preamplifier 5 is connected with the neutron detector 3, and the preamplifier 5 is Also connected to the power supply 4 that provides energy for the signal processing device, such as figure 2 shown.

[0054] Preamplifier selects the spectrum amplifier module of Canberra 2022 model for use in the present embodiment; Amplifier matches with preamplifier, and screening counter can select Siemens PLC (S7-200) high-speed counter HC4 for use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com