Stepless speed changer

一种无级变速器、腔体的技术,应用在车辆变速箱、传动装置、流体传动装置等方向,能够解决不具备柔性传动功能、装置结构复杂、制造成本高等问题,达到实现大功率柔性传动场合、传动过程柔性、实现自动匹配的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

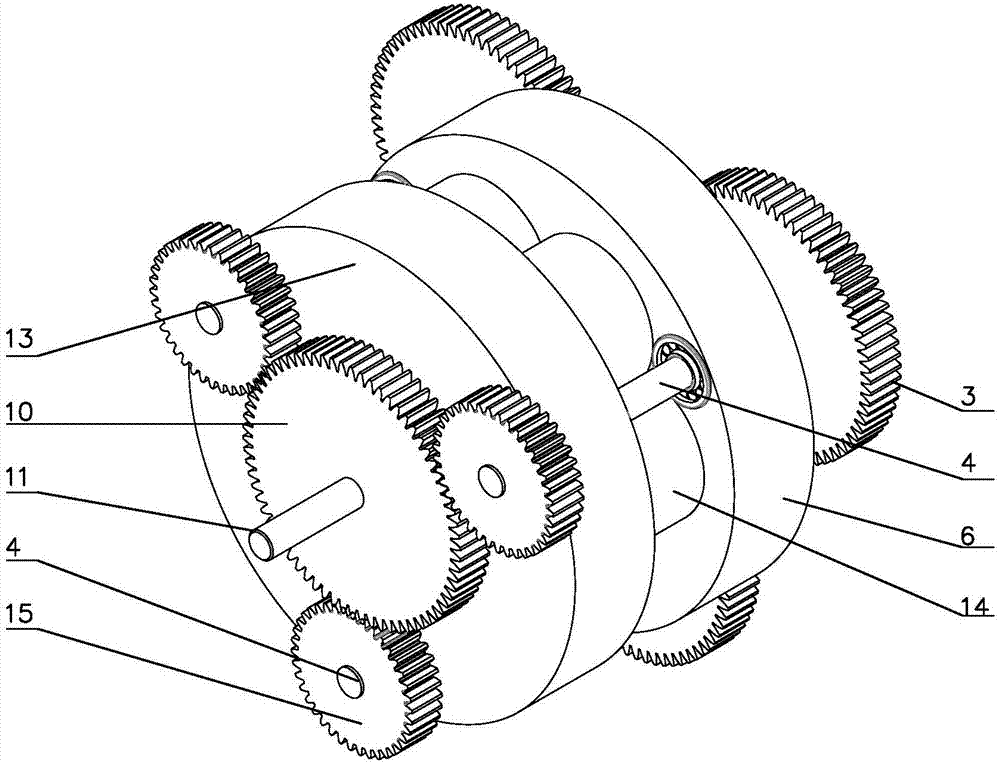

[0038] Such as Figure 1-Figure 5As shown, it is an embodiment of a continuously variable transmission of the present invention, which is provided with an input planetary gear set 101 and an output planetary gear set 102, and between the input planetary gear set 101 and the output planetary gear set 102 is a The cavity planet carrier 104, the cavity planet carrier 104 includes the cavity input end cover 6, the cavity output end cover 13, and the bucket wheel cavity shell is fixed between the cavity input end cover 6 and the cavity output end cover 13 14. The inner side of the planetary gear set 101 at the input end is connected to the input end cover 6 of the cavity, the inner side of the planetary gear set 102 at the output end is connected to the output end cover 13 of the cavity, and the side of the input end cover 6 of the inner cavity of the bucket wheel cavity housing 14 There is a bucket wheel planetary gear set 103; the input end planetary gear set 101 includes an inpu...

Embodiment 2

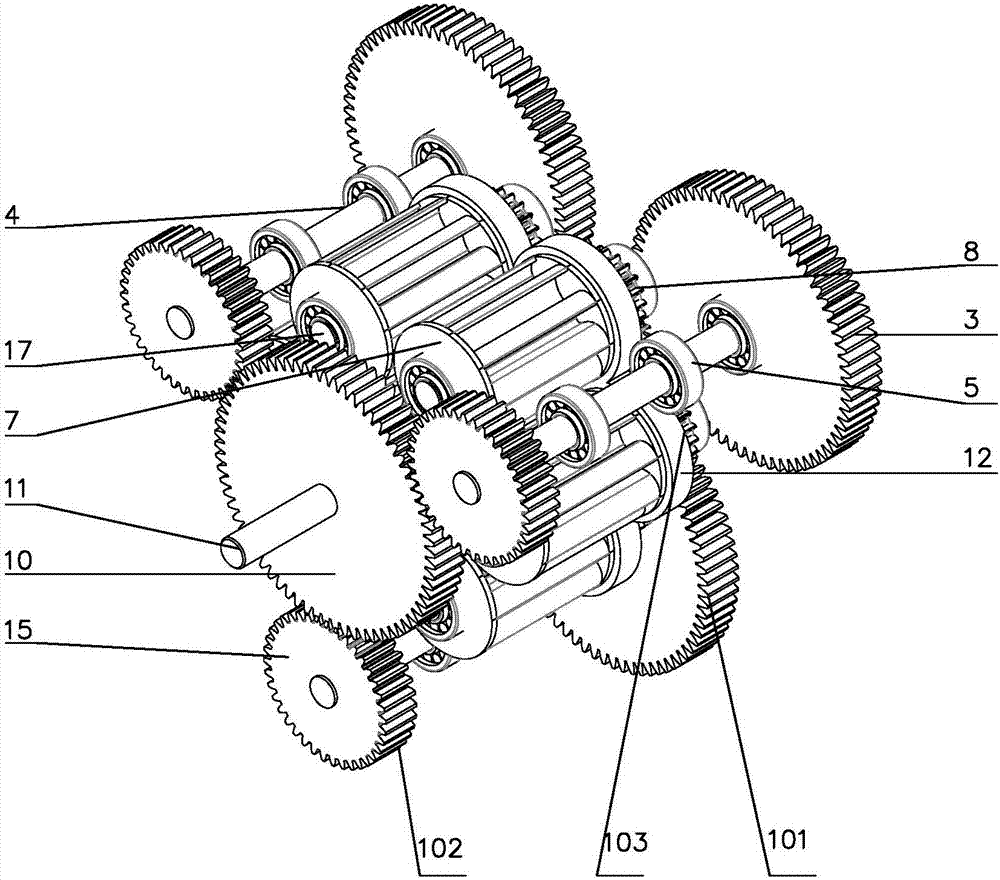

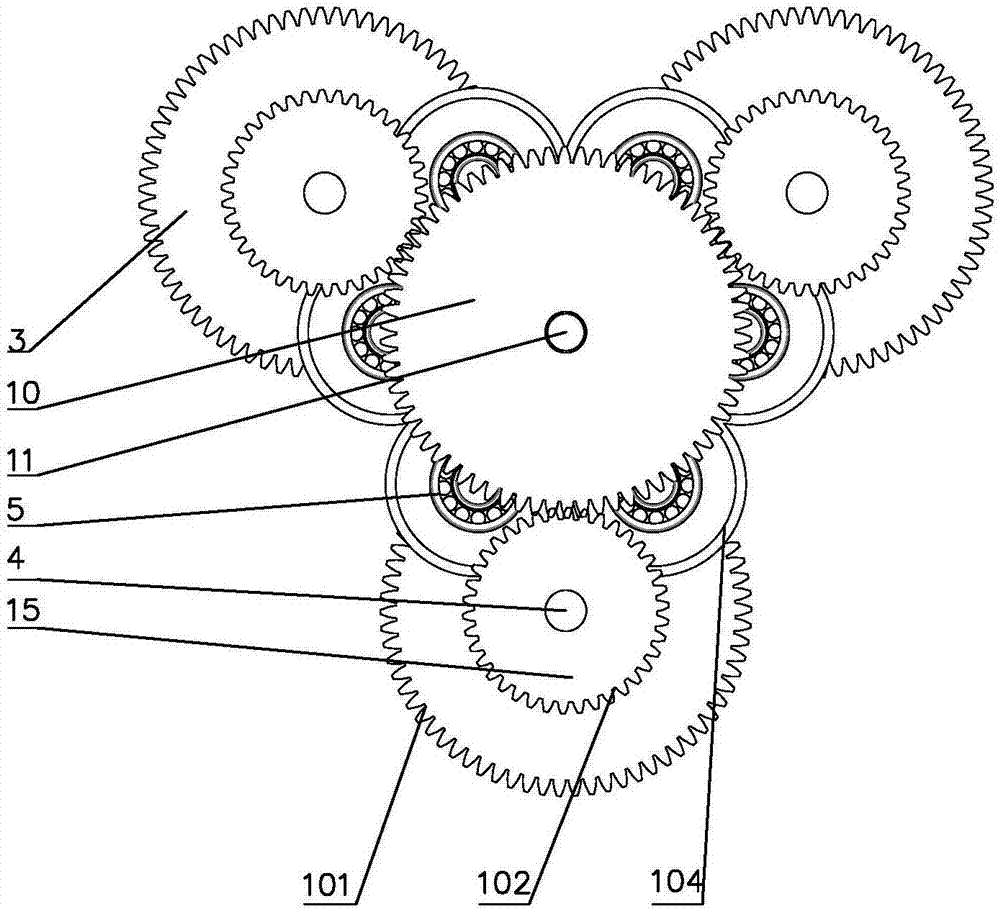

[0048] Figure 6-Figure 9 It is the second embodiment of the present invention. It is provided with a bucket wheel planetary gear set 103 and an output end planetary gear set 102. The inner side of the bucket wheel planetary gear set 103 is provided with a cavity planet carrier 104, and the cavity planet carrier 104 includes a cavity input end cover. 6. The cavity output end cover 13, the bucket wheel cavity housing 14 is fixed between the cavity input end cover 6 and the cavity output end cover 13, and the cavity input end cover 13 and the bucket wheel cavity housing 14 are fixed. There is an input planetary gear set 101 between them; the bucket wheel planetary gear set 103 includes a bucket wheel sun gear 9 and nine bucket wheel planetary gears 8, the bucket wheel sun gear 9 and the bucket wheel planetary gear 8 are meshed and connected, and the bucket wheel sun gear There is an input shaft 1 in the middle of 9, and the input shaft 1 passes through the input end cover 6 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com