Insert-molded article and method for producing insert-molded article

A technology of insert molding and manufacturing method, which is applied in the field of insert molding products and the manufacturing field of insert molding products, can solve the problems of complicated operation of arranging multiple terminals, and achieves the effect of improving the freedom of arrangement and suppressing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

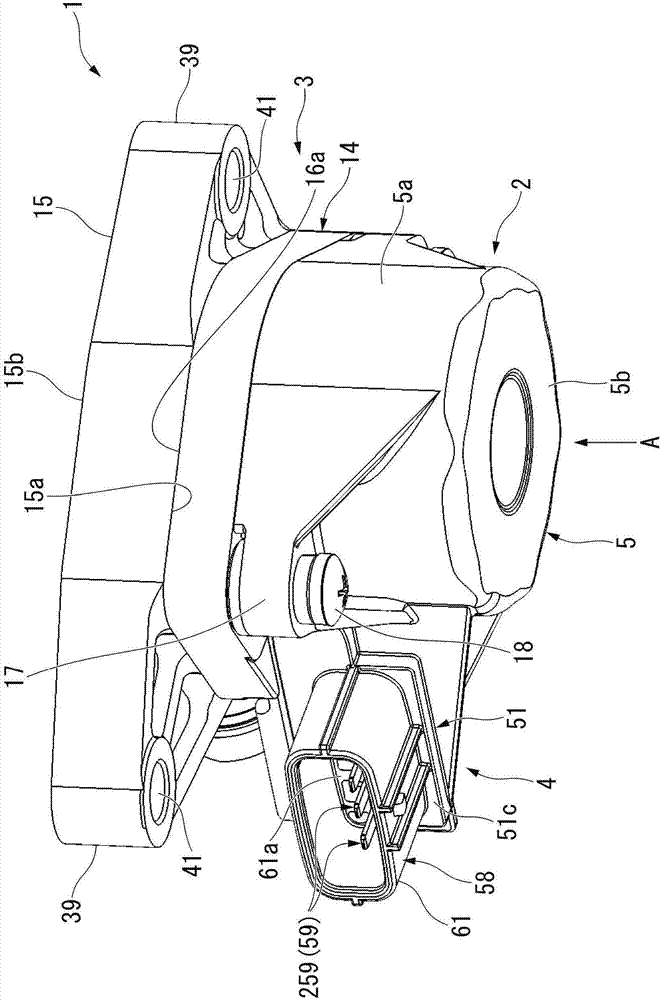

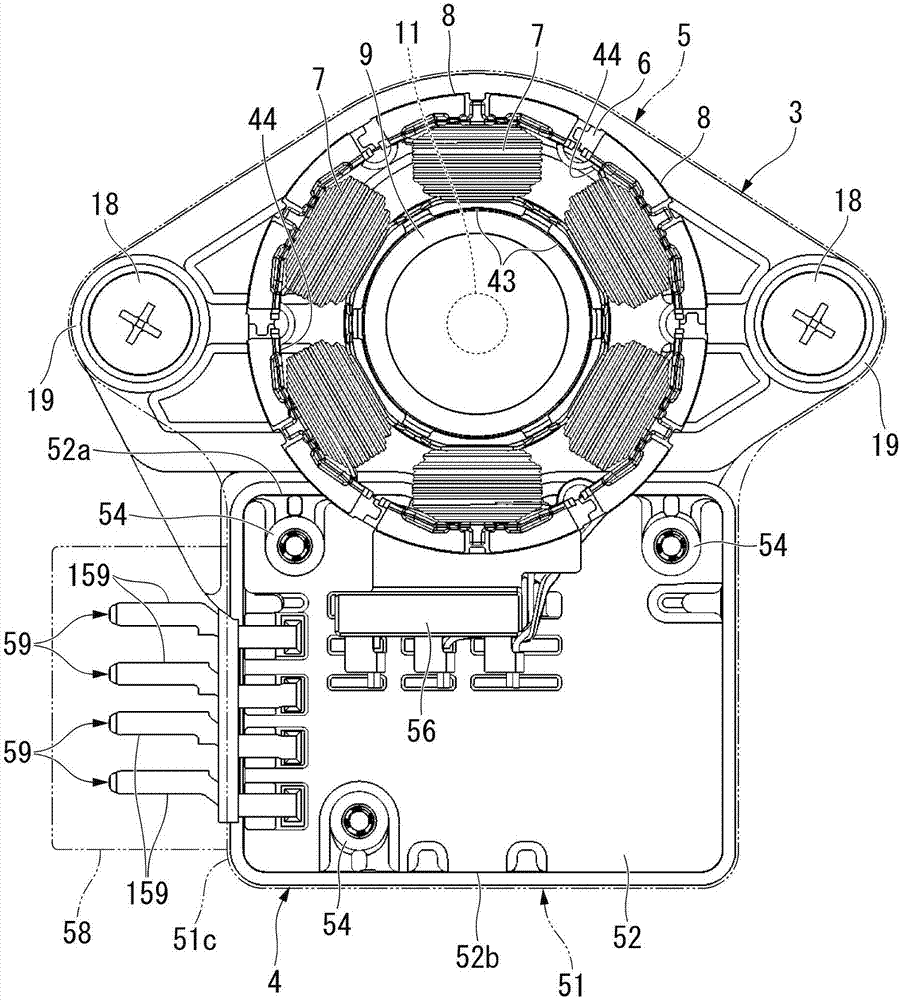

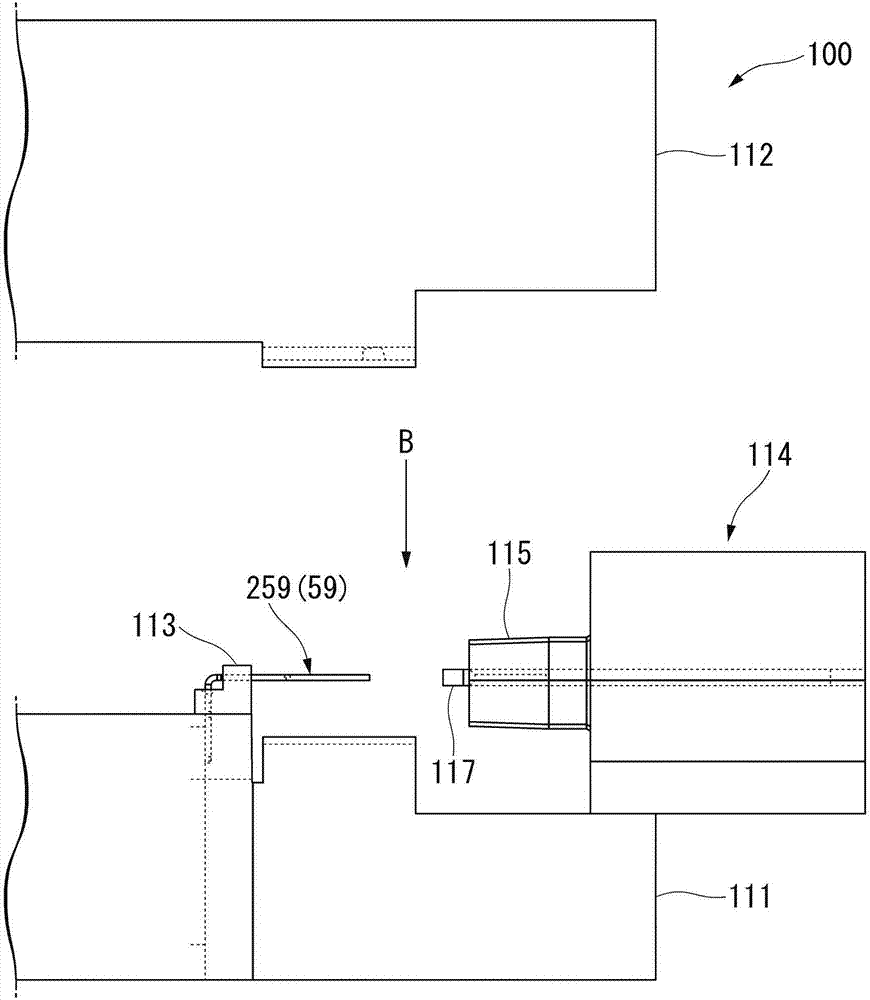

[0048] figure 1 It is a perspective view of an electric pump 1 using a motor case 5 which is an insert molded product, figure 2 yes figure 1The A-direction view of , shows the state through the motor housing 5 .

[0049] Such as figure 1 , figure 2 As shown, the electric pump 1 is, for example, a member for driving a transmission (both not shown) mounted in an automobile and supplying oil to the transmission. The electric pump 1 integrates a motor part 2, a pump part 3, and a control part 4. The pump part 3 is connected to the motor part 2 and arranged coaxially with the motor part 2. The control part 4 is arranged between the motor part 2 and the pump. Between the parts 3, and arranged on the outer peripheral surface side of the motor part 2 and the pump part 3.

[0050] In addition, in the following description, the axial direction of the rotating shaft 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com