A rotary beating device for making shoes

A rotary, shoe technology, applied to insoles, shoe uppers, footwear, etc., can solve the problems of time-consuming and laborious, low hammering efficiency, etc., and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

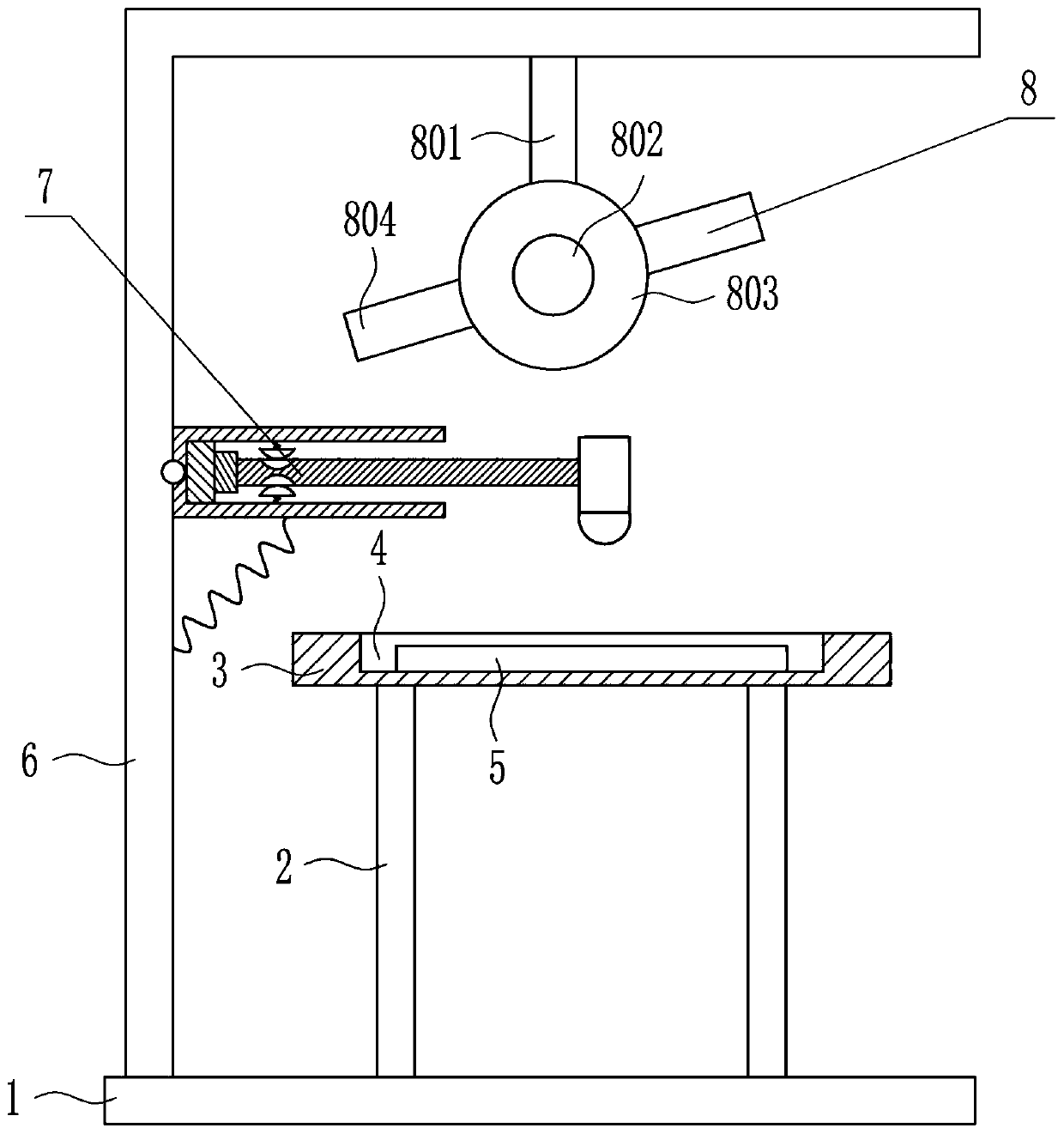

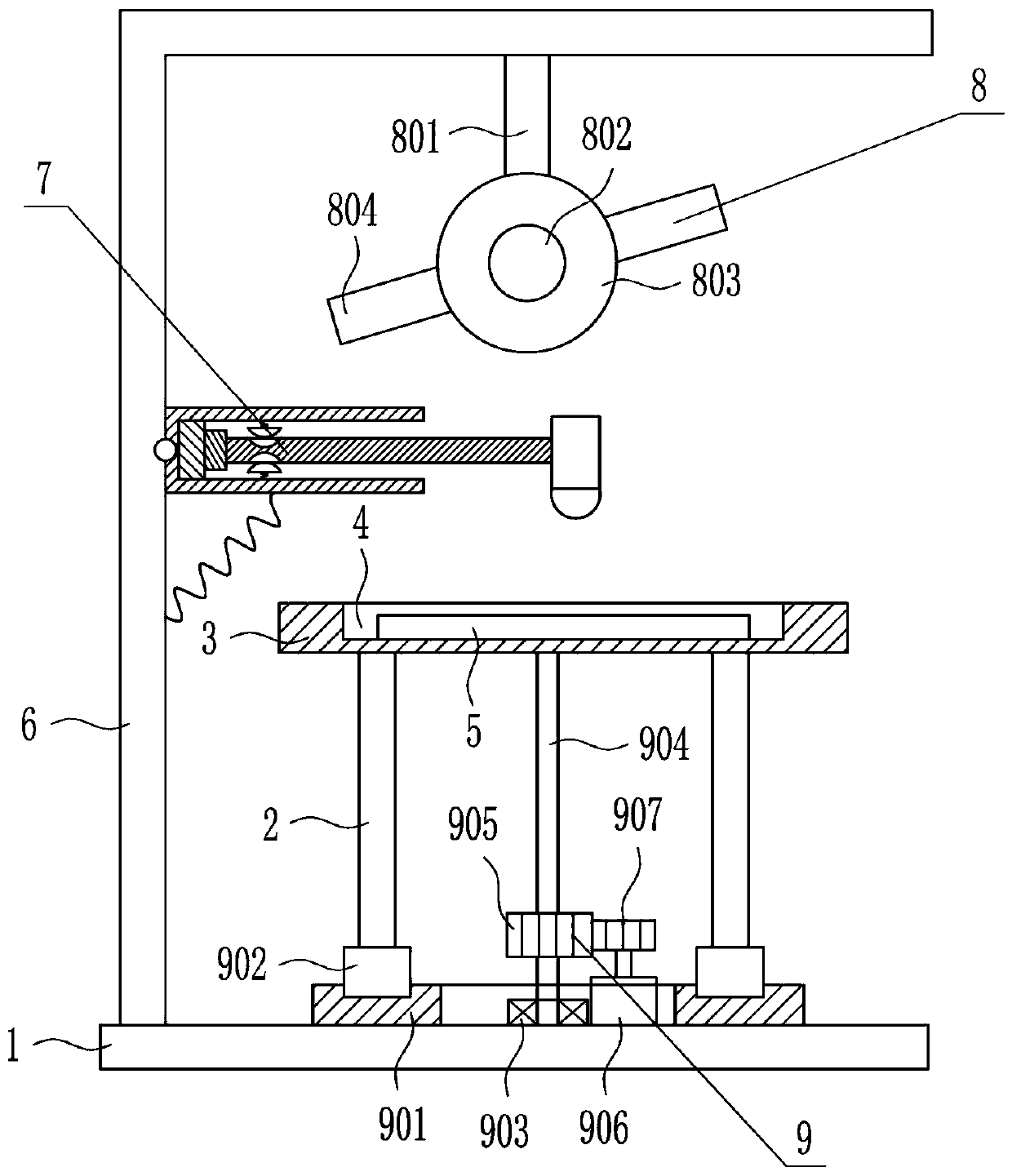

[0027] A rotary hammering device for making shoes, such as Figure 1-4 As shown, it includes base plate 1, pole 2, placement plate 3, suction cup 5, 7-shaped plate 6, beating device 7 and driving device 8, and the top of base plate 1 is vertically connected with two poles 2 by bolts, two The struts 2 are left and right symmetrical, and the tops of the two struts 2 are connected with a placement plate 3 by bolts. The base plate 1 top on the left side of pole 2 is connected with 7-shaped plate 6 by bolts, and the inner side middle part of 7-shaped plate 6 is provided with beating device 7, and the middle part of 7-shaped plate 6 inner tops is provided with driving device 8.

Embodiment 2

[0029] A rotary hammering device for making shoes, such as Figure 1-4 As shown, it includes base plate 1, pole 2, placement plate 3, suction cup 5, 7-shaped plate 6, beating device 7 and driving device 8, and the top of base plate 1 is vertically connected with two poles 2 by bolts, two The struts 2 are left and right symmetrical, and the tops of the two struts 2 are connected with a placement plate 3 by bolts. The base plate 1 top on the left side of pole 2 is connected with 7-shaped plate 6 by bolts, and the inner side middle part of 7-shaped plate 6 is provided with beating device 7, and the middle part of 7-shaped plate 6 inner tops is provided with driving device 8.

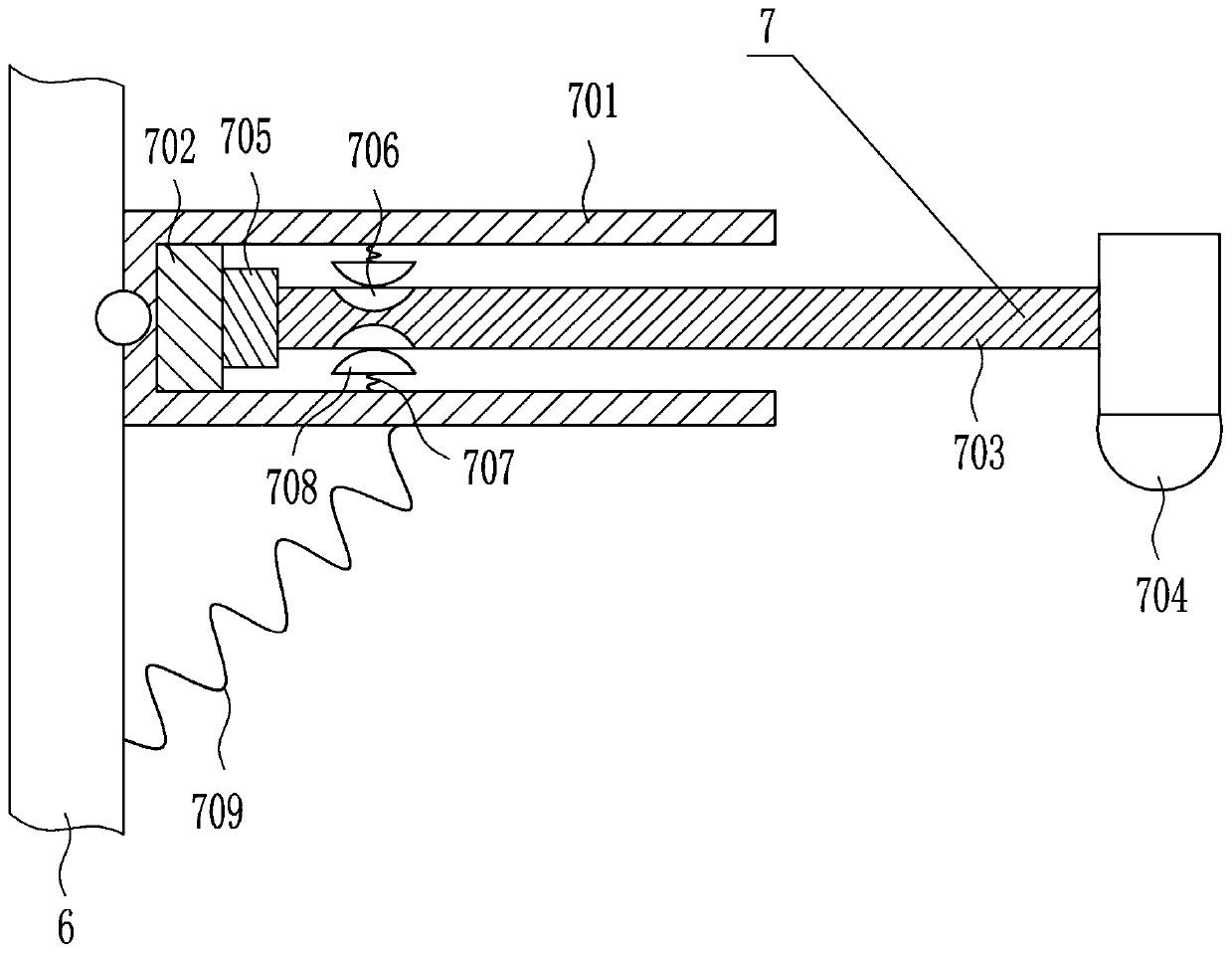

[0030]The beating device 7 includes a hollow sleeve 701, a magnet 702, a connecting rod 703, a tup 704, an iron block 705, a first spring 707, an arc block 708 and a second spring 709, and the left side of the hollow sleeve 701 passes through the The hinge part is hingedly connected with the middle part of...

Embodiment 3

[0032] A rotary hammering device for making shoes, such as Figure 1-4 As shown, it includes base plate 1, pole 2, placement plate 3, suction cup 5, 7-shaped plate 6, beating device 7 and driving device 8, and the top of base plate 1 is vertically connected with two poles 2 by bolts, two The struts 2 are left and right symmetrical, and the tops of the two struts 2 are connected with a placement plate 3 by bolts. The base plate 1 top on the left side of pole 2 is connected with 7-shaped plate 6 by bolts, and the inner side middle part of 7-shaped plate 6 is provided with beating device 7, and the middle part of 7-shaped plate 6 inner tops is provided with driving device 8.

[0033] The beating device 7 includes a hollow sleeve 701, a magnet 702, a connecting rod 703, a tup 704, an iron block 705, a first spring 707, an arc block 708 and a second spring 709, and the left side of the hollow sleeve 701 passes through the The hinge part is hingedly connected with the middle part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com