Welding device

A technology of welding device and sliding connection, which is applied to the parts of the connecting device, coupling device, welding accessories, etc., can solve the problems of plug joint loosening, user loss, pin bending deformation, etc., so as to prevent the plug from loosening and increase safety Effects on sex and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

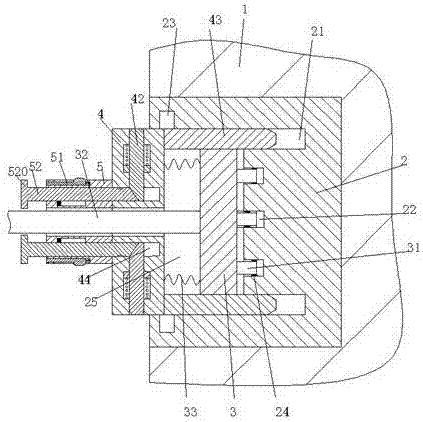

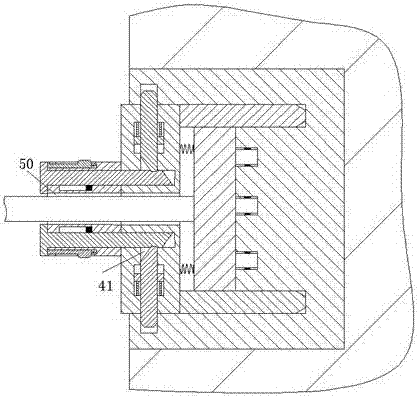

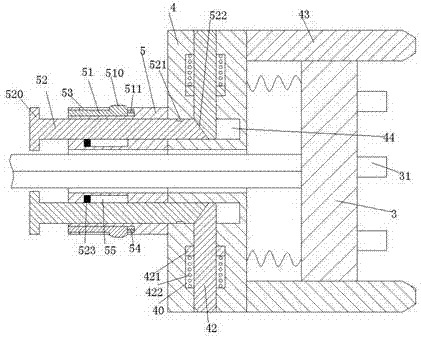

[0019] Combine below Figure 1-5 The present invention will be described in detail.

[0020] refer to Figure 1-5 , a welding device according to an embodiment of the present invention, including a power distribution base 2 fixedly installed in a distribution box 1, a power terminal 3 matched with the power distribution base 2, and a power terminal for protecting the power distribution base 2. The protection device for the electric terminal 3, the left and right sides of the distribution box 1 are equipped with fixing rings 101 on the upper and lower sides, and the fixing rings 101 are provided with fixing holes 102, and the fixing rings 101 are used for For the fixing of the distribution box 1, the power distribution seat 2 is provided with a sliding connection cavity 25 with the mouth facing left, and an insertion slot 22 is provided in the right end wall of the sliding connection cavity 25, and an insertion slot 22 is set in the insertion slot 22. There is a power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com