High-precision torsional miniature fixture structure suitable for high temperature superconducting tape application technology

A high-temperature superconducting tape and application technology technology, applied in the field of high-precision torsion micro-clamp structure, can solve the problems of complex and critical performance research technology lag, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

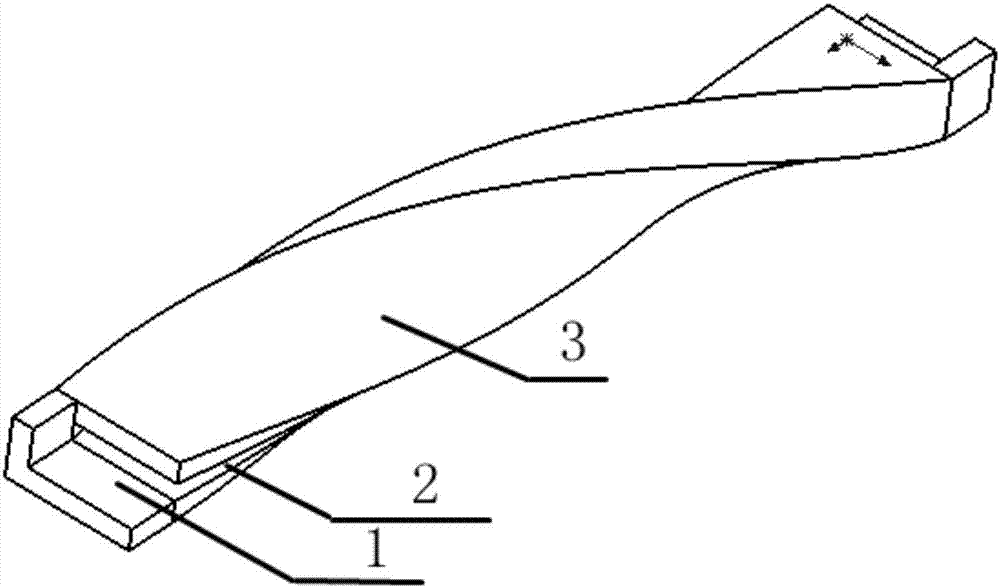

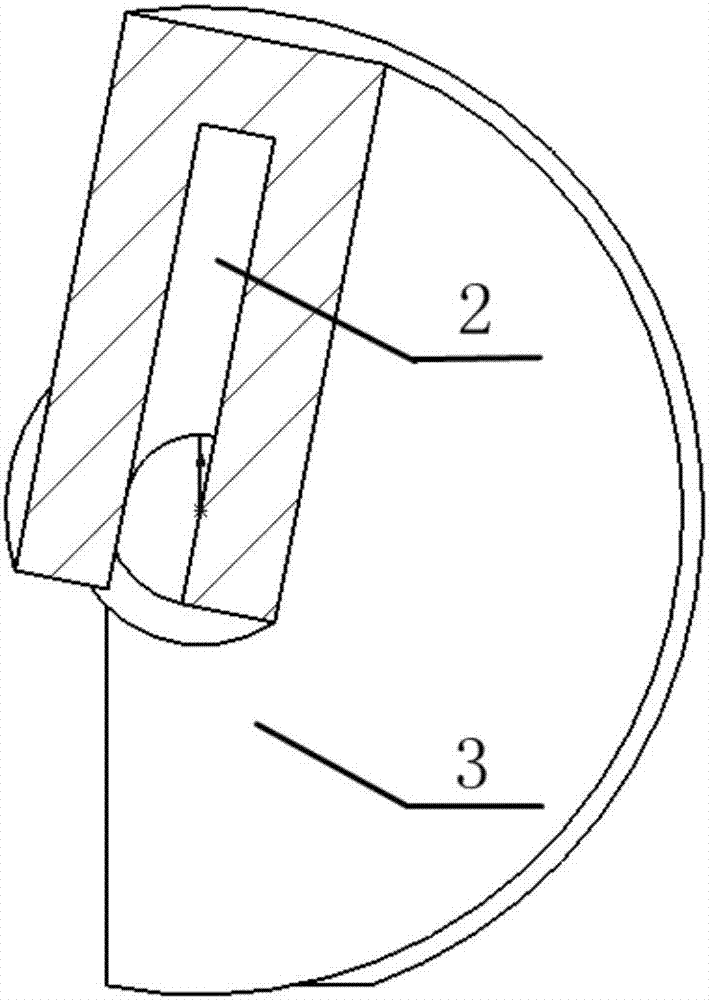

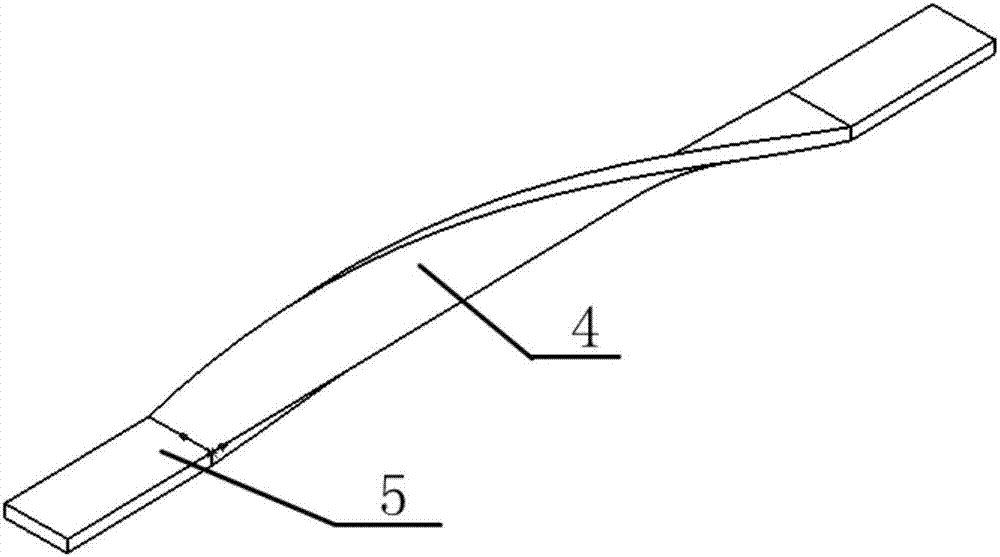

[0026] See attached picture.

[0027] A high-precision torsion miniature fixture structure suitable for high-temperature superconducting strip application technology, characterized in that: the entire fixture forming process adopts 3D printing technology, which realizes the high precision of the fixture model, and the fixture is divided into a middle torsion part 3 and two ends. Straight line section 1. The torsion angle of the torsion fixture can be independently designed according to the design requirements. There is a torsion groove 2 on the side of the torsion fixture. The width and depth of the side groove should be determined according to the quantity and specification of the YBCO strip. The groove is a twisted structure, so that the YBCO strip can be embedded from the side to realize the high-precision arbitrary twisting of the YBCO strip. The strip is also divided into torsion parts 4 inside the torsion fixture, and the YBCO high-temperature superconducting strip is emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com