Smart Onboard Airworthiness Instrument

An airworthiness instrument and intelligent technology, applied in the field of new hydrodynamic performance testing devices, can solve the problem of inability to guarantee the absolute stability of the mother ship, and achieve the effects of excellent testing performance, guaranteed strength requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

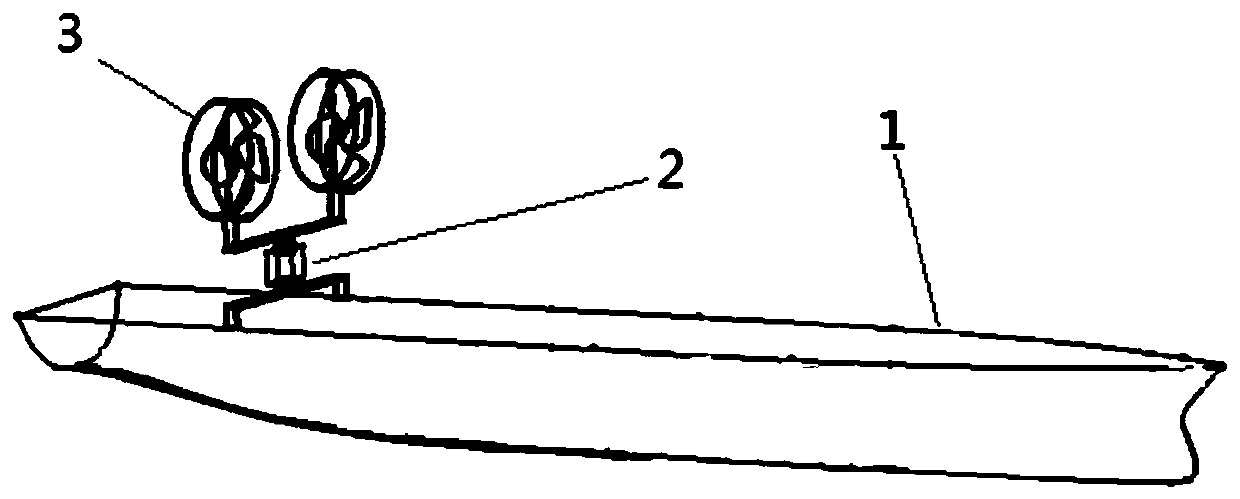

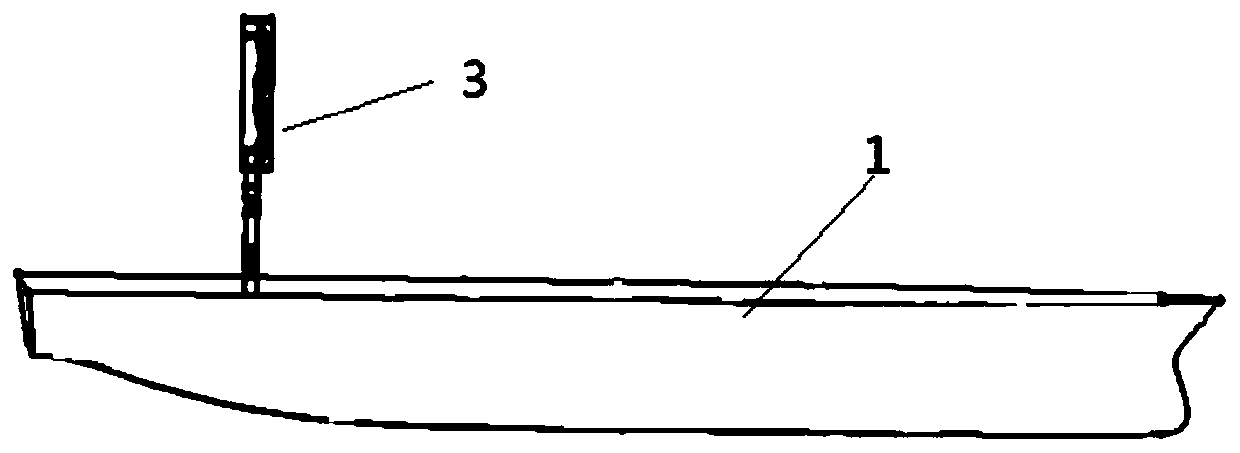

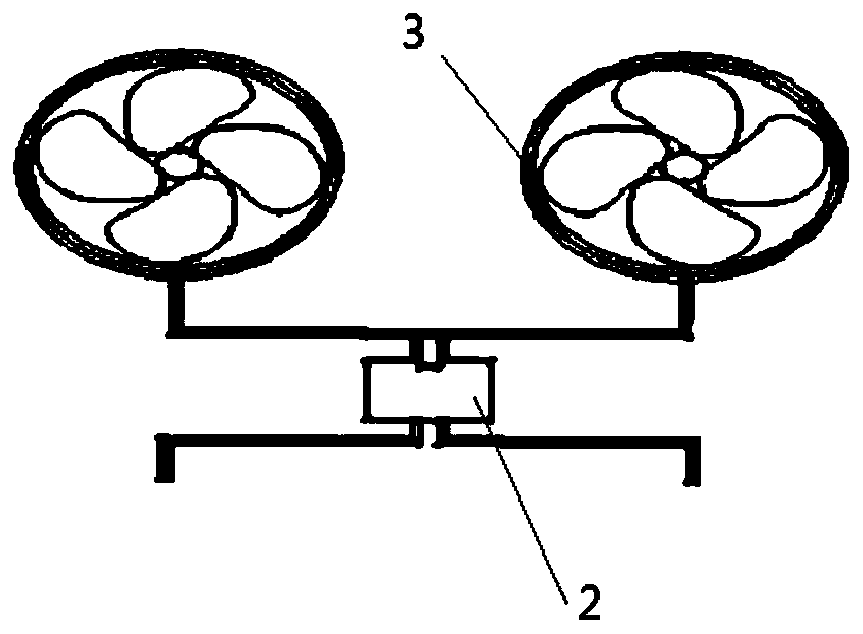

[0021] combine Figure 1 to Figure 4 , the present invention is an intelligent on-board airworthiness instrument, including two large fans 3 arranged at the stern of the ship through brackets, and a force measuring device 2 located between the fans and the hull 1 of the self-propelled model. The two fans should be arranged along the width of the ship, and the diameter of the fan 3 is about 0.08-0.3B (B is the width of the self-propelled model ship), and they are on the same horizontal plane. The two wind turbines are installed in parallel at the tail of the self-propelled model hull, 0.2-0.5L away from the stern (L is the designed captain of the self-propelled model hull). The force measuring device is installed between the fan and the ship model, 0.2-0.4D away from the deck of the ship model (D is the hull depth of the self-propelle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap