Connection and conversion mechanism for translation type motor three-phase winding

A three-phase winding and connection conversion technology, which is applied to the shape/style/structure of motors and winding conductors, electric vehicles, etc., can solve problems such as power system waste, avoid power excess, improve safety and reliability, and extend The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

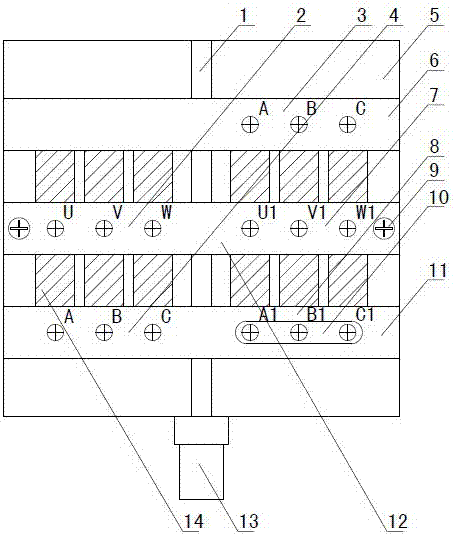

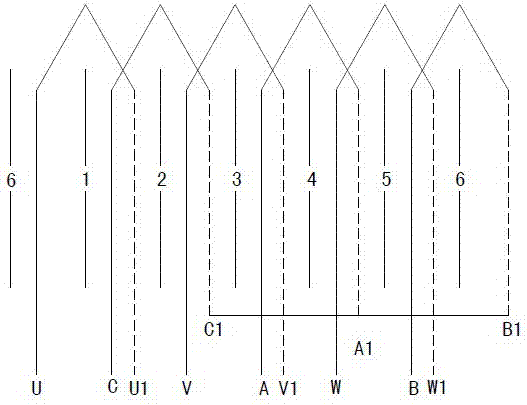

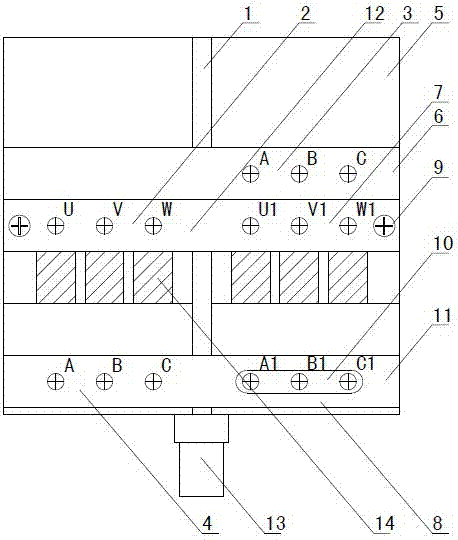

[0029] Figure 1~9 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~9 The present invention will be further described.

[0030] Such as figure 1 As shown, the translational motor three-phase winding connection conversion mechanism includes a rectangular bottom plate 5, and a stator terminal board 12 is arranged horizontally in the middle of the bottom plate 5, and the stator terminal board 12 is fixed on the bottom plate 5 by a fixing bolt 9 at each two ends thereof. upper surface.

[0031] On the left side and the right side of the stator terminal board 12 are respectively provided with a stator left connection part 2 and a stator right connection part 7, and on the stator left connection part 2, there are three connection terminals arranged side by side at equal intervals from left to right: The U terminal, the V terminal and the W terminal are respectively used to connect the upper layers of the U-phase winding, the V-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com