A transformer installation structure

A technology for installation structures and transformers, which is applied in the installation/support/suspension of transformers/reactors, substations installed on poles, etc., which can solve problems affecting the reliability and safety of transformers, unstable installation, etc., and improve convenience , Improved safety, improved simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

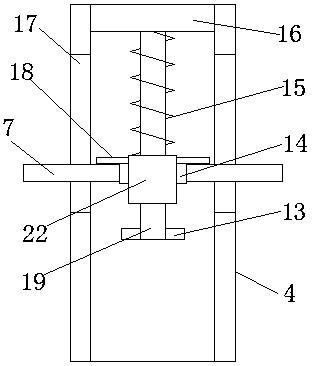

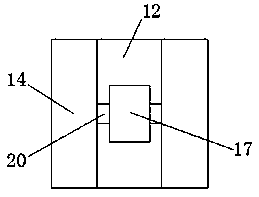

[0017] refer to Figure 1-4 , a transformer installation structure, including a transformer 21 and two columns 11 arranged side by side, the top of the column 11 is provided with a first support plate 1, the bottom of the transformer 21 is equipped with a second support plate 5, the first support plate 1 The upper surface is provided with a mounting block 10, the upper surface of the mounting block 10 is provided with a dovetail groove 8, and the inside of the dovetail groove 8 is provided with a plurality of dovetail blocks 3, and the dovetail block 3 slides along the side wall of the dovetail groove 8, and the dovetail block 3 The upper surface is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com