Manufacturing method and system for customized shoes

A manufacturing method and technology of shoes, applied to measuring devices for feet or shoe lasts, footwear, clothing, etc., can solve problems such as high comfort, low manufacturing cost, and short manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

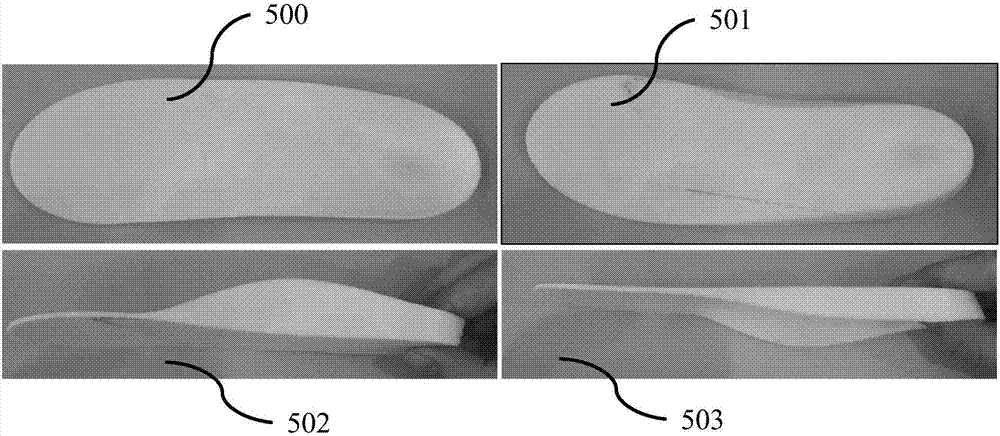

[0175] The following methods are used to make customized shoes: collect foot data; The 3D model is used to make shoes. The inner sole of the shoe fits the real sole completely (that is, the inner sole of the shoe corresponds to the shape of the real sole). etc.) the minimum linear distance <0.48cm.

[0176] In particular, the present invention, through the investigation of 100 user experience data, uses statistical data to determine that when the minimum linear distance between the inner side of the vamp and the upper part of the foot is increased to "0.48cm" (average data), the user's comfort level is significantly reduced. The survey process and data are as follows:

[0177] Survey method: randomly (age, sex, height, weight and other factors are all random) select 100 people, and make 10 pairs of shoes for each person. The characteristics of the shoes include: (1) the sole of each shoe exactly matches the shape of the corresponding sole; (2) the minimum straight-line dista...

Embodiment 2

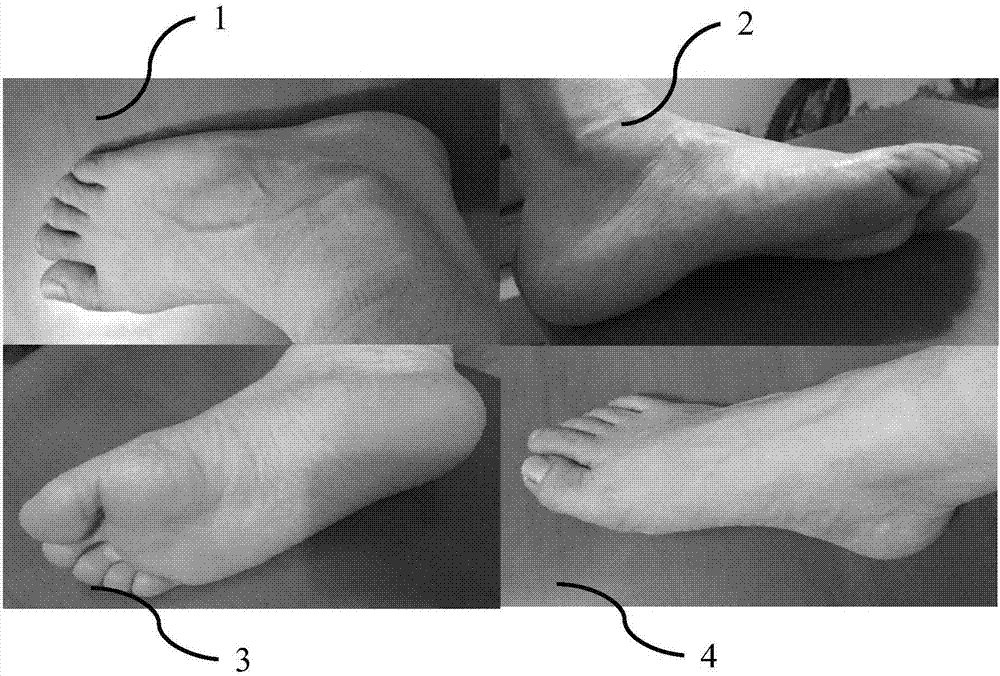

[0179] The following method is used to make customized shoes: the user takes 4 foot pictures with the mobile phone camera function, and the user measures to obtain the foot length information; uses the network to collect 4 foot pictures and foot length information; uses the collected foot pictures to perform three-dimensional Modeling to form a three-dimensional model of the foot that is consistent or nearly identical to the shape of the real foot; shoes are made based on the three-dimensional model of the foot, and the inner sole of the shoe fits the real sole completely (that is, the inner sole of the shoe and the shape of the real sole Correspondingly), the minimum linear distance between any point on the inside of the vamp and the upper part of the foot (including toes, instep, ankle, etc.) is <0.48cm.

[0180] In this embodiment, there are many ways to compose the 4 foot pictures taken by the user, in order to obtain complete foot image data. It is best to meet the follow...

Embodiment 3

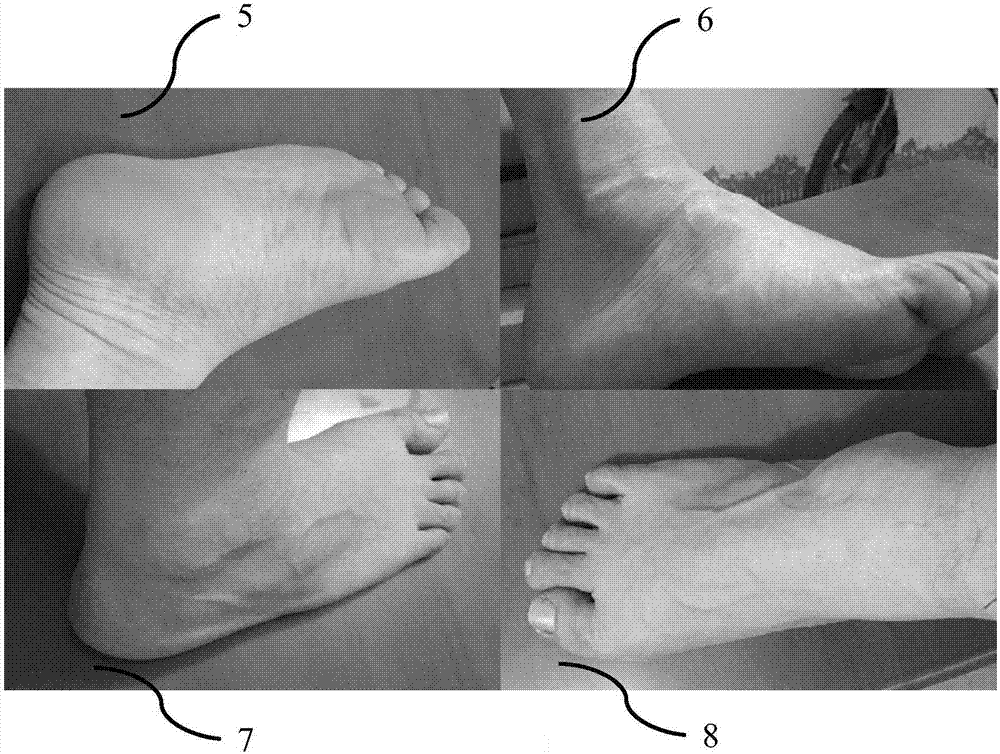

[0185] The following method is used to make customized shoes: the user takes 2 pictures of feet with the camera function of the mobile phone, and the user measures and obtains the foot length information; uses the network to collect 2 foot pictures and foot length information; uses the collected foot pictures to establish a primary 3D model, perform image compensation and restoration on the primary 3D model, and obtain the final 3D model of the foot. The sole fits perfectly (that is, the inner sole of the shoe corresponds to the shape of the real sole of the foot), and the minimum linear distance between any point on the inside of the upper and the upper part of the foot (including toes, instep, ankle, etc.) is <0.48cm.

[0186] In this embodiment, the foot information recorded in the two foot pictures taken by untrained users is generally incomplete, so it is necessary to supplement and repair the defective images in the process of 3D modeling. In order to use two photos to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com