Orthopedic shoe manufacturing method and system based on pressure imaging and three-dimensional modeling technologies

A 3D modeling and 3D model technology, applied in footwear, foot or shoe last measurement devices, clothing, etc., can solve problems such as inability to pressure data to propose solutions, less consideration, differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

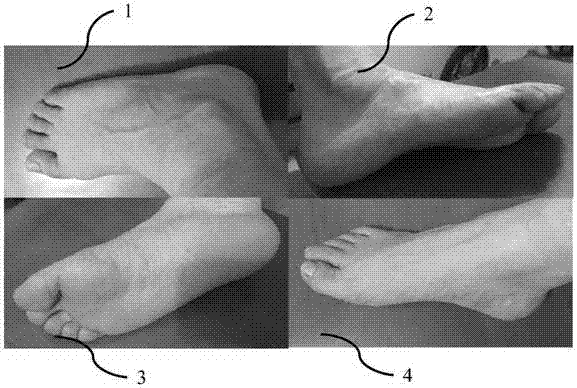

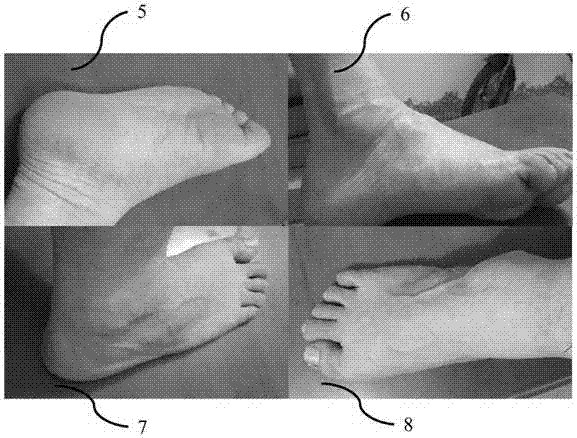

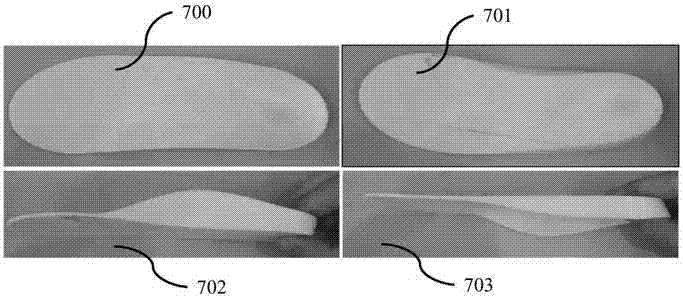

[0190] The orthopedic shoes are made by the following method: (1) Collect source data: collect patient’s health data, collect plantar pressure distribution data, and collect foot images at the same time, that is, use a shooting device to take no less than 2 foot images to obtain source data; (2) Use the network to collect source data: use a wired network or wireless network to collect the source data to the data processing platform; (3) Pressure distribution data imaging: use a computer to convert the plantar pressure distribution data into plantar three-dimensional image data; (4) ) Foot image recognition and 3D modeling: use computer to restore, enhance, and segment the foot image in the source data, convert it into secondary data that can be used for 3D modeling, and then use the secondary data to extract 3D features, mark, Coordinate conversion, point cloud stitching, and global optimization of the model to form a primary three-dimensional model of the foot; (5) Model fitti...

Embodiment 2

[0194] Orthopedic shoes are made by the following method: (1) source data collection: collect the patient’s health data, collect plantar pressure distribution data, and collect foot images at the same time, that is, use a shooting device to take 4 foot images to obtain source data; (2) Use the network to collect source data: use a wired network or wireless network to collect the source data to the data processing platform; (3) pressure distribution data imaging: use the computer to convert the plantar pressure distribution data into plantar three-dimensional image data; (4) foot Image recognition and 3D modeling: use the computer to restore, enhance, and segment the foot image in the source data, convert it into secondary data for 3D modeling, and then use the secondary data for 3D feature extraction and marking, coordinate conversion and Point cloud stitching and model global optimization to form a primary 3D model of the foot; (5) Model fitting: Fit the 3D image data of the s...

Embodiment 3

[0200]Orthopedic shoes are made by the following method: (1) source data collection: collect the patient’s health data, collect plantar pressure distribution data, and collect foot images at the same time, that is, use a shooting device to take 2 foot images to obtain source data; (2) Use the network to collect source data: use a wired network or wireless network to collect the source data to the data processing platform; (3) pressure distribution data imaging: use the computer to convert the plantar pressure distribution data into plantar three-dimensional image data; (4) foot Image recognition and 3D modeling: use the computer to restore, enhance, and segment the foot image in the source data, convert it into secondary data for 3D modeling, and then use the secondary data for 3D feature extraction and marking, coordinate conversion and Point cloud stitching and model global optimization to form a primary 3D model of the foot; (5) Model fitting: Fit the 3D image data of the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com