Manufacturing method and system for custom shoes based on pressure imaging and three-dimensional modeling technologies

A technology of three-dimensional modeling and three-dimensional modeling, which is applied to footwear, foot or shoe last measurement devices, clothing, etc., and can solve problems such as differences, short production cycles, and inability to put forward solutions based on pressure data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

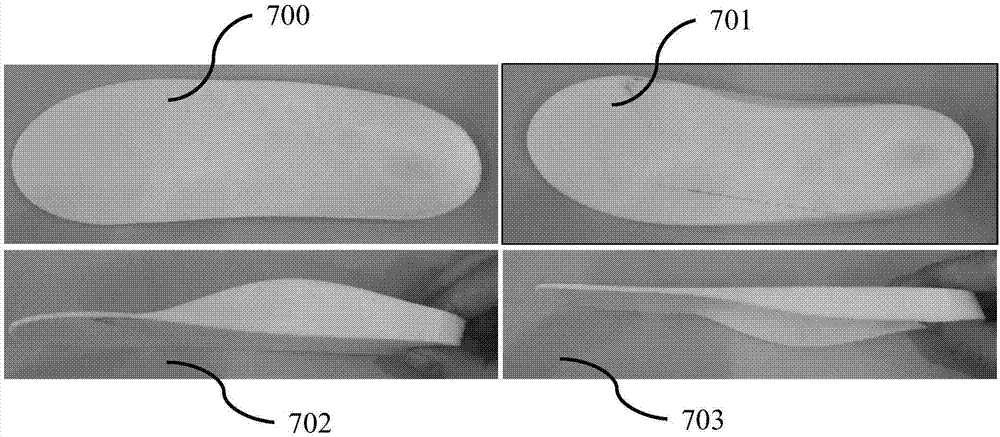

[0171] Use the following methods to make customized shoes: collect plantar pressure distribution data to obtain source data; use the network to collect source data; three-dimensional modeling, that is, use the source data to establish a three-dimensional model of the sole corresponding to the real sole shape; make shoes, that is, according to The three-dimensional model of the sole is used to make the sole, and then the sole is combined with the upper, heel and other parts to form a complete shoe. The inner sole of the shoe is completely fitted to the real sole (that is, the inner sole of the shoe corresponds to the shape of the real sole. ), the minimum linear distance between any point on the inner side of the upper and the upper part of the foot (including toes, instep, ankle, etc.) is less than 0.48cm. .

[0172] In particular, the present invention uses statistical data to investigate 100 user experience data to determine that when the minimum linear distance between the inn...

Embodiment 2

[0175] Use the following methods to make customized shoes:

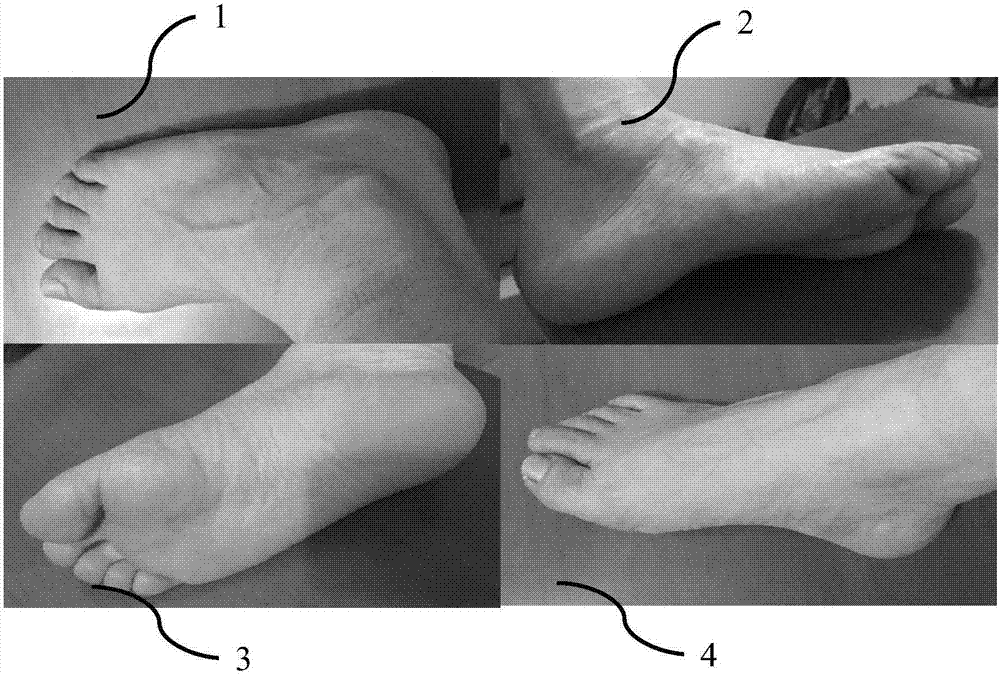

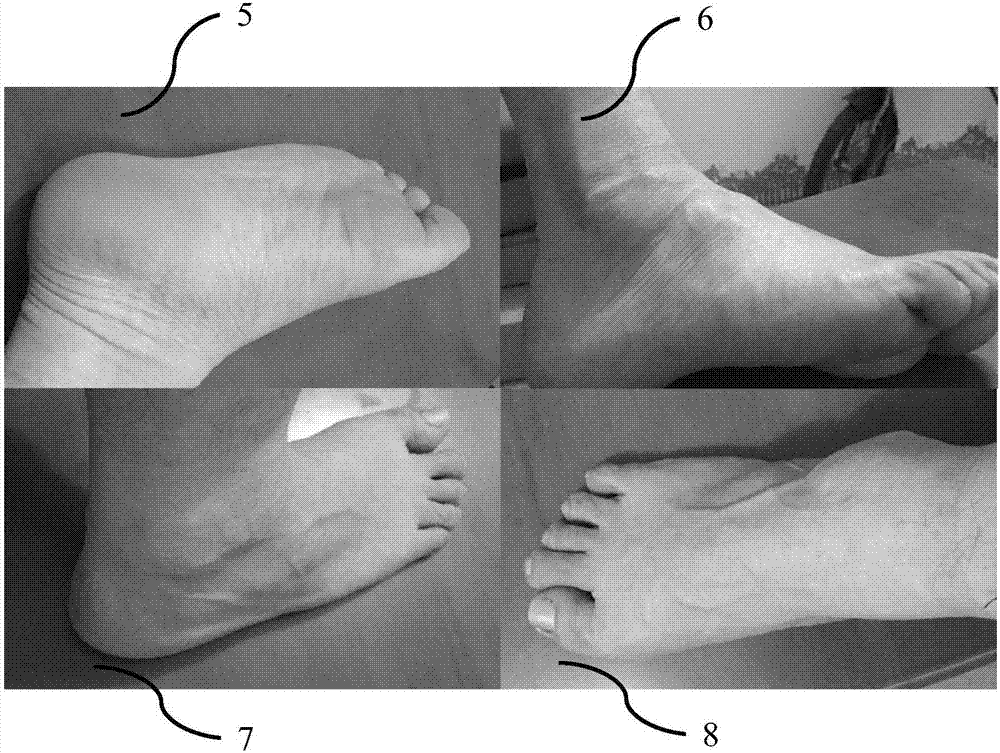

[0176] (1) Collecting foot data: Collecting plantar pressure distribution data, and at the same time collecting foot images, that is, using a camera to take a lot of 4 foot images to obtain source data; (2) Using the network to collect foot data: using a wired network Or the wireless network collects the source data to the data processing platform; (3) Pressure distribution data imaging: Use computer to convert plantar pressure distribution data into plantar 3D image data; (4) Foot image recognition and 3D modeling: Use computer Restore, enhance, and segment the foot images in the source data, and convert them into secondary data for 3D modeling, and then use the secondary data to perform 3D feature extraction and marking, coordinate conversion, point cloud stitching, and global model optimization to form Primary three-dimensional model of the foot; (5) Model fitting: Fit the three-dimensional image data of the sole obt...

Embodiment 3

[0182] The following methods are used to make customized shoes: (1) Collect foot data: Collect plantar pressure distribution data, and at the same time collect foot images, that is, use a camera to take 2 foot images to obtain source data; (2) Use the network to collect feet Data: Use wired network or wireless network to collect source data to the data processing platform; (3) Pressure distribution data imaging: Use computer to convert plantar pressure distribution data into plantar three-dimensional image data; (4) Foot image recognition and three-dimensional Modeling: Use a computer to restore, enhance, and segment the foot images in the source data, and convert them into secondary data that can be used for three-dimensional modeling. Then use the secondary data for three-dimensional feature extraction and marking, coordinate conversion and point cloud splicing, Global optimization of the model to form a three-dimensional model of the primary foot; (5) Model fitting: Fit the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com