Method for assembling houses with interlocking combined block assembly components

A chain, block technology, applied in building components, building structures, walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

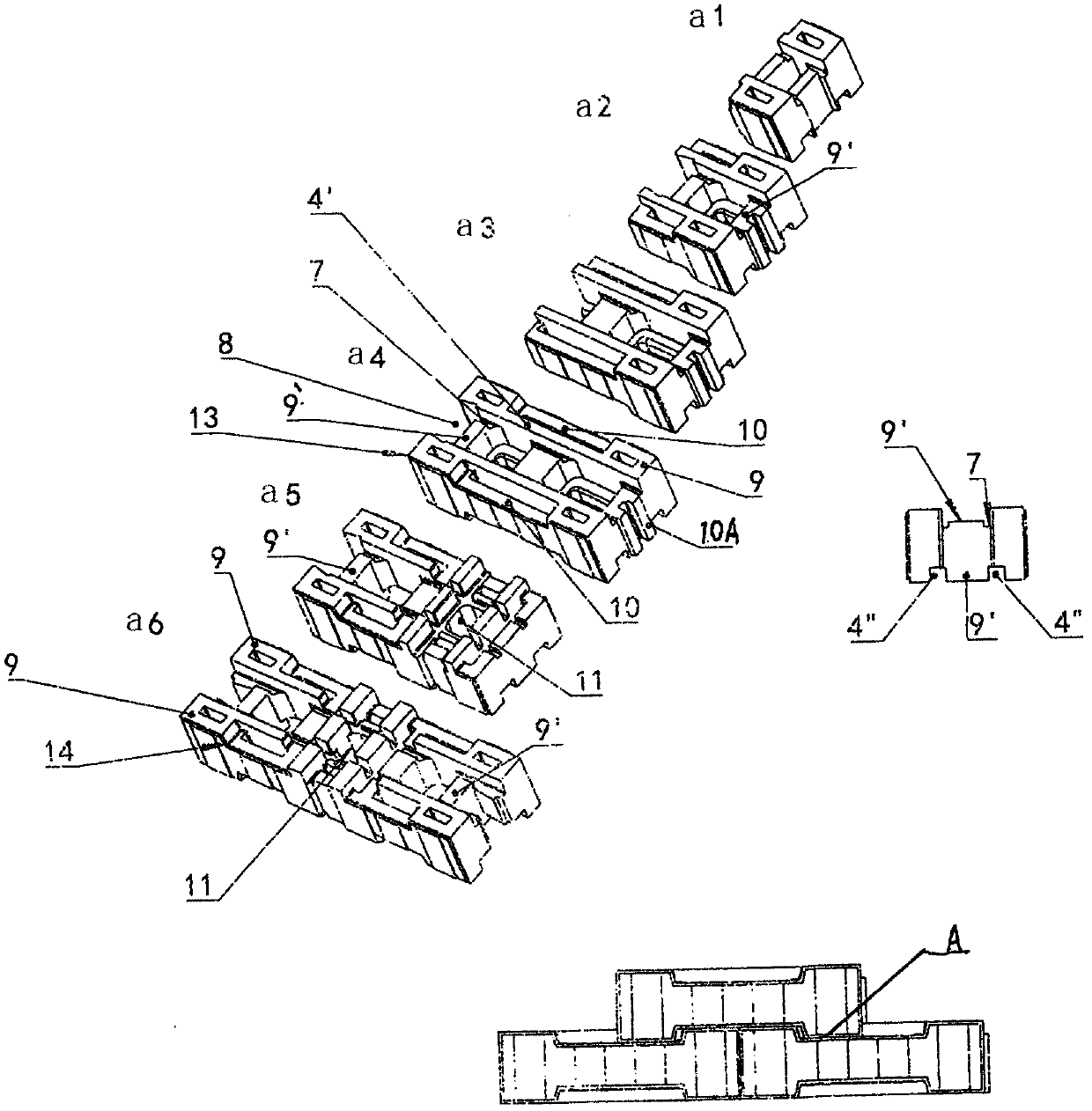

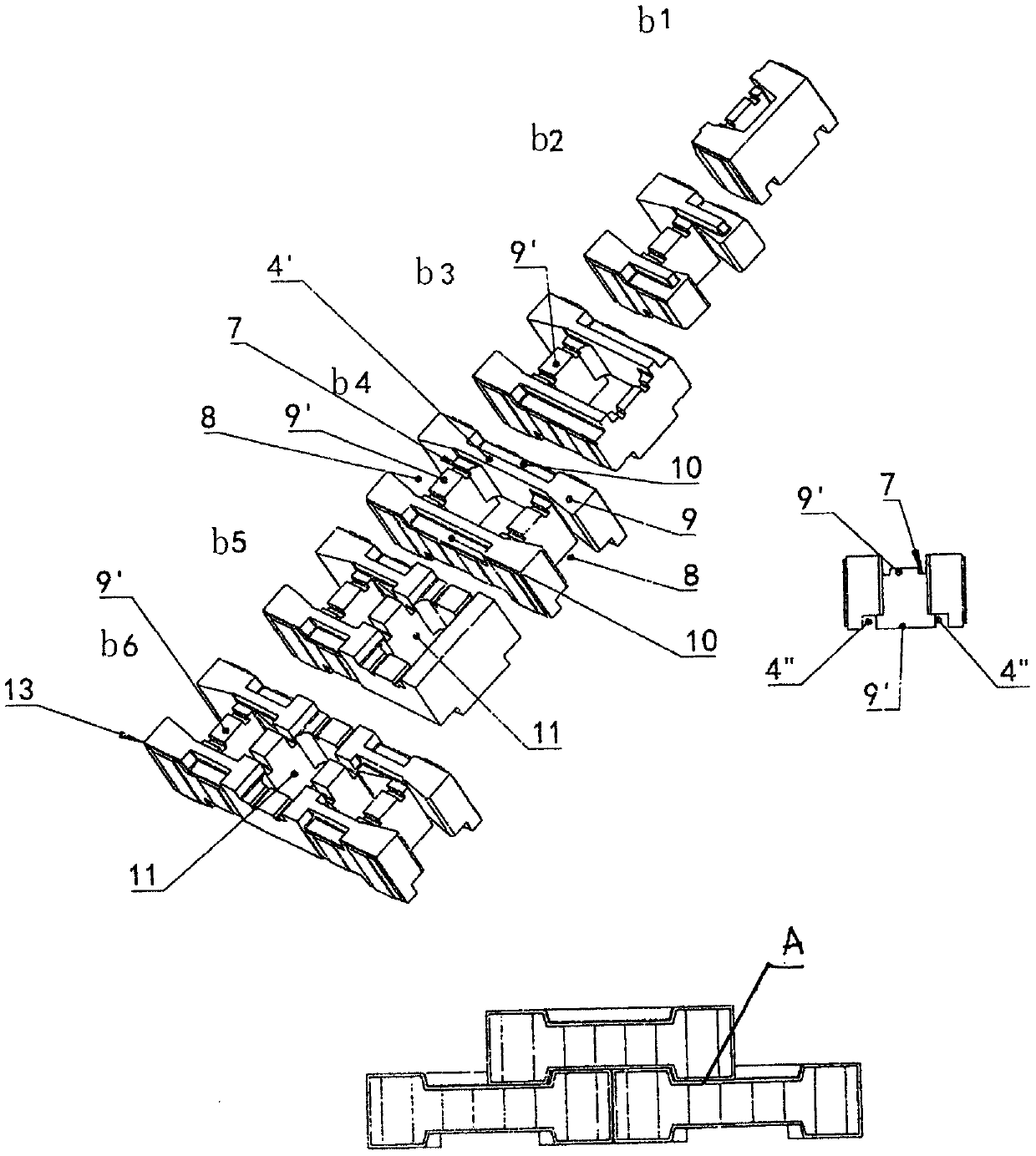

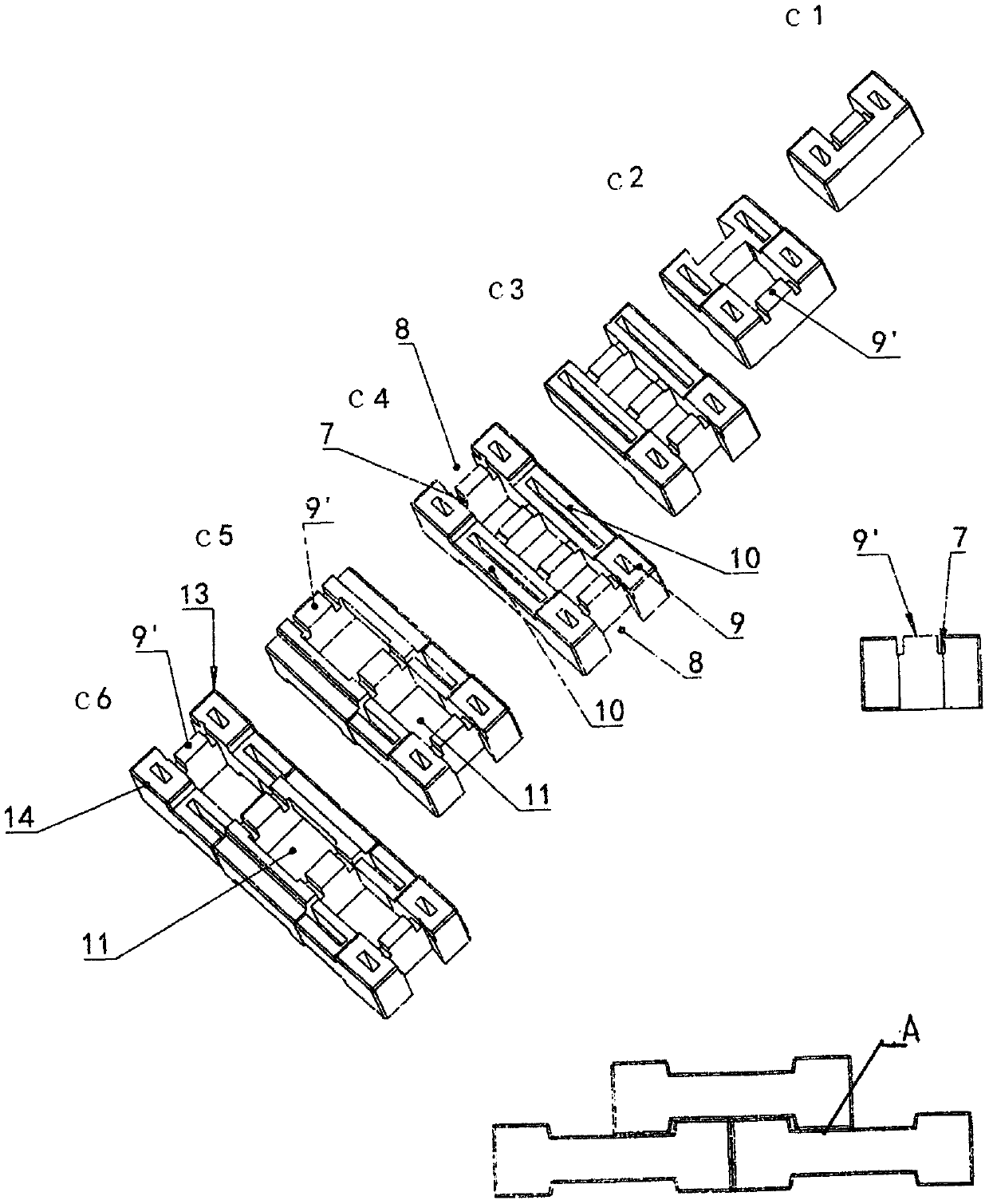

[0078] Such as figure 1 As shown, it is a three-row hole all-round multifunctional interlocking combination block, so figure 1 The main block a4 is the core, which constitutes a3, 2 / 4 a2, 1 / 4 a1, L-shaped a5, and T-shaped a6 blocks respectively of the length of the main block a4 to form a building block. The surface of the wall is A type of concave-convex dislocation interlocking mortar joint type combined block, which becomes the most basic part of the assembled structural column, beam, wall and floor that can finally be assembled into a house. figure 1 The 9 and 10 shown in the figure form the up, down, left, and right concave-convex interlocking structure relationship of the block; 4″ and 4′ form the horizontal left and right interlocking relationship between the blocks, and 4′ is connected to the inside of the convex locking tenon 9 at both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com