Screw compressor element

A technology of screw compressors and components, applied in pump components, mechanical equipment, machines/engines, etc., can solve problems such as impeding good filling of blade gaps and mixing loss in hollow parts, and achieve the effect of eliminating mixing loss and easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

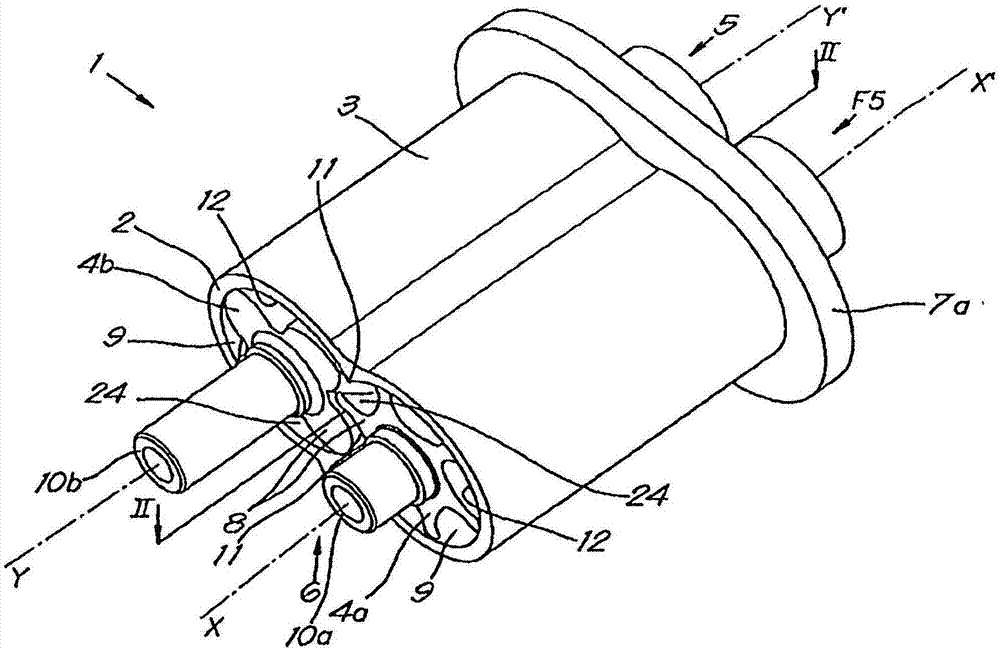

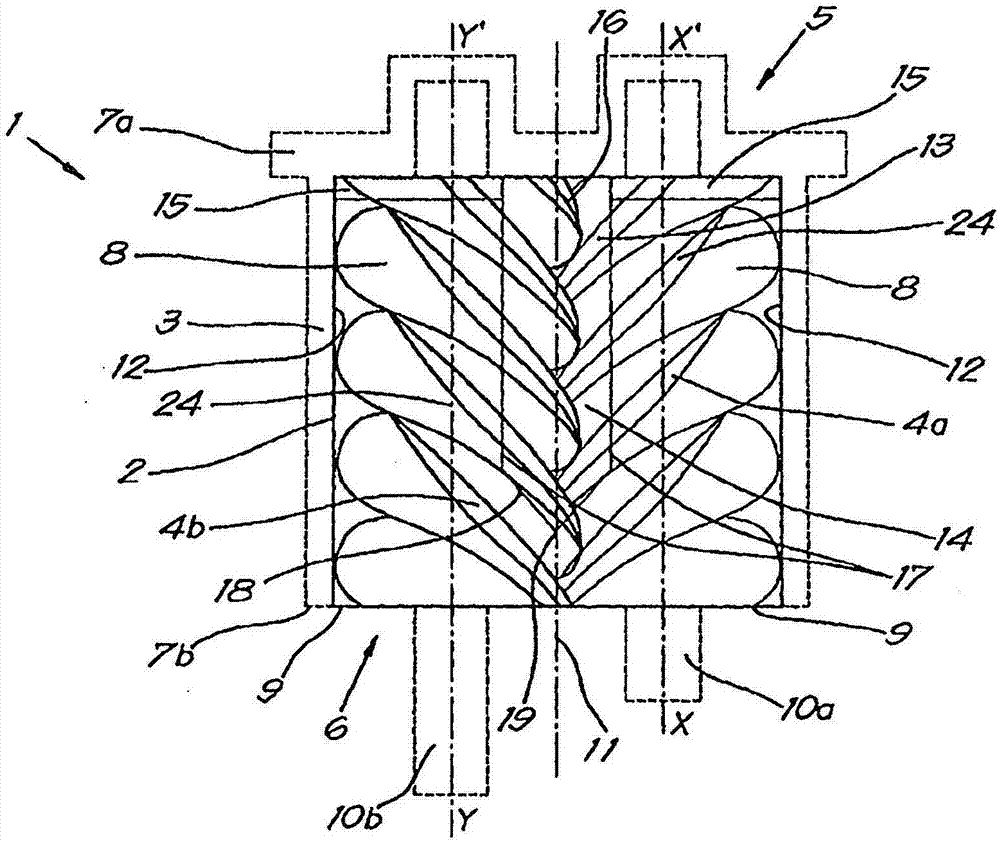

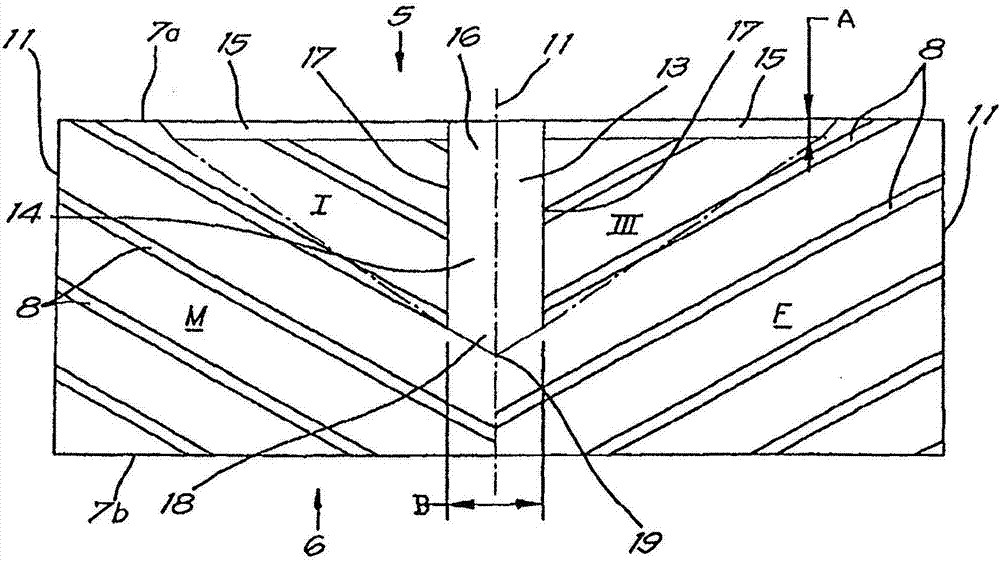

[0051] figure 1 A perspective view of the screw compressor element 1 according to the present invention is schematically shown. Two screw rotors 4a and 4b, namely, a female screw rotor 4a and a male screw rotor 4b, are fixed in at least the double cylindrical chamber 2 of the housing 3.

[0052] The screw compressor element 1 has an air inlet side 5 and an air outlet side 6. The air inlet end face 7a of the housing 3 is shown at the air inlet side 5.

[0053] For the sake of clarity, other components of the screw compressor element 1 are not shown, such as the exhaust port end face 7b on the exhaust port side 6, bearings and seals.

[0054] in figure 1 In this, it can be clearly seen that the spiral rotors 4a and 4b are provided with blades 8 which mesh with each other to rotate and are fixed in the double cylindrical chamber 2.

[0055] The chamber 2 is composed of two single cylindrical rotor chambers 9, in which the axes X-X' and Y-Y' of the rotor chamber 9 coincide with the axes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com