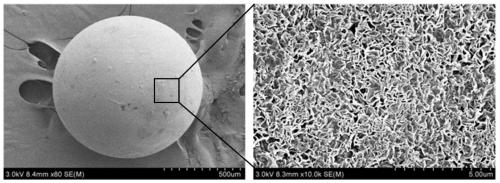

A method for deep removal of heavy metals in water by resin-based copper phosphate nanoflower coating

A copper phosphate and nanoflower technology, applied in chemical instruments and methods, water pollutants, adsorbed water/sewage treatment, etc., can solve problems such as the lack of targeted mass transfer performance of functional groups, the limitation of pore volume, and the limitation of large-scale applications. , to solve the slow adsorption and mass transfer rate, solve the technical bottleneck, and improve the effect of masking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 10g of cation exchange resin D001 (produced by Hangzhou Zhengguang Industrial Co., Ltd.) was placed in 1L of Tris-HCl buffer solution with a concentration of 0.1mol / L, and then 120g of dopamine (DA) hydrochloride was added to the above solution to make dopamine ( The mass fraction of DA) hydrochloride was 12%, and the temperature was controlled at 20 °C, and stirred for 24 h in the dark to form a uniform polydopamine (PDA) coating on the surface of the resin, namely PS-PDA; 10 g of PS-PDA material was placed in 1 L mole CuSO with a concentration of 0.1mol / L 4 In the solution, react at room temperature for 6 hours to make Cu 2+ Stepwise diffusion and enrichment to the surface of PS-PDA to obtain the intermediate PS-PDA-Cu 2+ ; filtered and 10 g PS-PDA-Cu 2+ Add to 1L of phosphate buffered saline (PBS) containing bovine serum albumin, wherein the concentration of bovine serum albumin is 0.05mg / mL, the buffer solution in phosphate buffered saline (PBS) is controlled to 0...

Embodiment 2

[0020] 50g of cation exchange resin D113 (produced by Hangzhou Zhengguang Industrial Co., Ltd.) was placed in 1L of 2mol / L Tris-HCl buffer solution, and then 500g of dopamine (DA) hydrochloride was added to the above solution to make dopamine (DA) The mass fraction of hydrochloride is 50%. The temperature was controlled at 60 °C, and stirred for 36 h in the dark to form a uniform polydopamine (PDA) coating on the resin surface, namely PS-PDA; 50 g of PS-PDA material was placed in 1 L of CuSO with a molar concentration of 5 mol / L. 4 In the solution, react at room temperature for 24 hours to make Cu 2+ Stepwise diffusion and enrichment to the surface of PS-PDA to obtain the intermediate PS-PDA-Cu 2+ ; filtered and 50g PS-PDA-Cu 2+The material was added to 1 L of phosphate buffered saline (PBS) containing bovine serum albumin, in which the concentration of bovine serum albumin was 0.5 mg / mL, and the buffer solution in phosphate buffered saline (PBS) was controlled to 0.2 mol / L,...

Embodiment 3

[0023] Place 30g of cation exchange resin 001x7 (produced by Tianjin Bochum Resin Technology Co., Ltd.) in 800mL of 0.5mol / L Tris-HCl buffer solution, then add 160g of dopamine (DA) hydrochloride to the above solution, dopamine (DA) ) The mass fraction of hydrochloride is 20%. The temperature was controlled at 40 °C, and stirred for 24 h in the dark to form a uniform polydopamine (PDA) coating on the resin surface, namely PS-PDA; 30 g of PS-PDA material was placed in 800 mL of CuSO with a molar concentration of 1 mol / L. 4 In the solution, react at room temperature for 12 hours to make Cu 2+ Stepwise diffusion and enrichment to the surface of PS-PDA to obtain the intermediate PS-PDA-Cu 2+ ; filtered and 30 g PS-PDA-Cu 2+ The material was added to 800 mL of phosphate buffered saline (PBS) containing bovine serum albumin, in which the concentration of bovine serum albumin was 0.1 mg / mL, the buffer solution in phosphate buffered saline (PBS) was controlled to 0.15 mol / L, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com