Pretreatment method for wastewater produced in o-isopropoxyphenol production process

A technology for ortho-isopropoxyphenol and wastewater production, which is applied in water/sewage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high oxidant cost, complex process, and high cost , to achieve the effect of low operating cost, simple operation and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

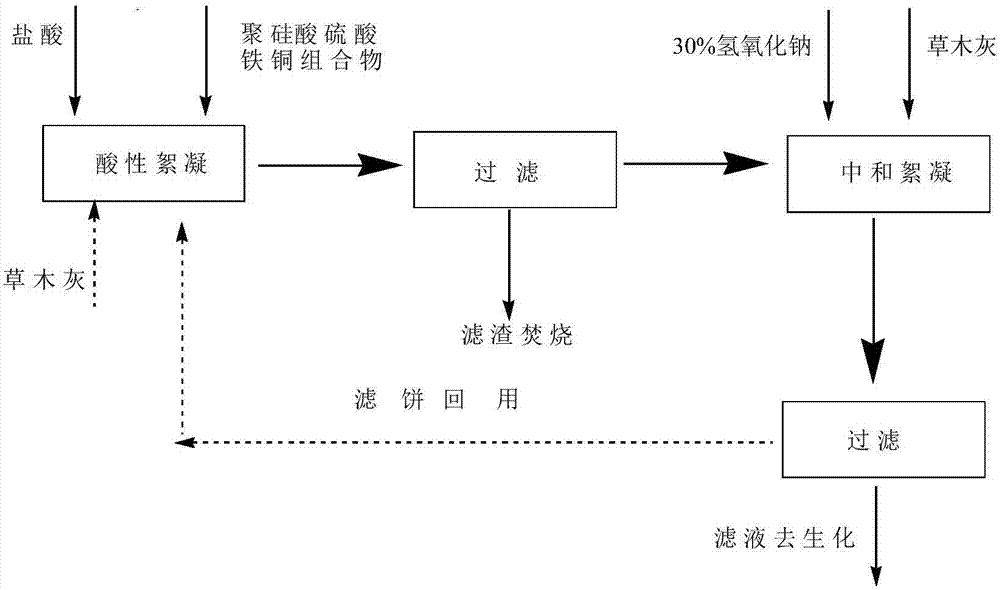

[0037] A kind of pretreatment method of ortho-propoxyphenol production waste water of the present invention (get the ortho-propoxyphenol production waste water (being called for short OP waste water) 600ml of a pesticide factory in Changde), such as figure 1 shown, including the following steps:

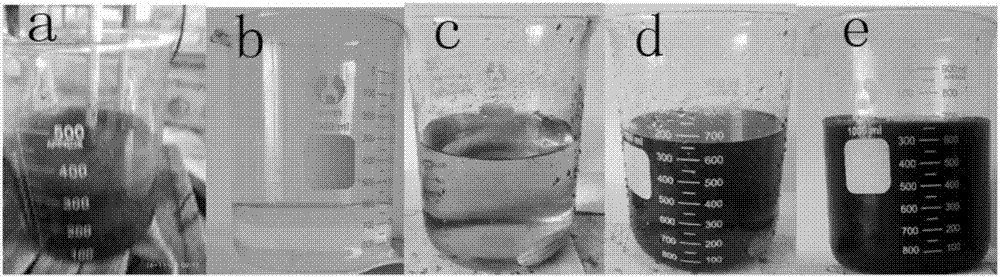

[0038](1) Acidic flocculation: add 10g of hydrochloric acid to adjust the pH to 5, stir at room temperature for 10 minutes, add 6g of wet plant ash and 4.8g of polysilicate iron copper sulfate composition to make the pH of the solution 3.5, continue to stir for 0.5 hours, filter, filter Cake 20.6g, go to solid waste incinerator for incineration;

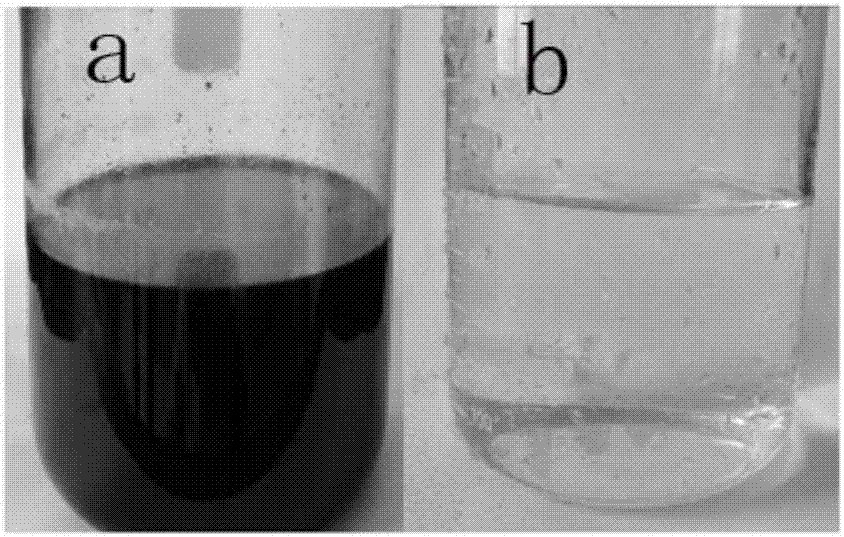

[0039] (2) Neutralization and flocculation: 600 g of the filtrate obtained in step (1) is poured into a beaker, and 7.63 g of 30% sodium hydroxide is slowly added in 5 minutes to adjust the pH to 8.5, then add plant ash 6 g and stir for 30 minutes, filter to obtain Colorless liquid 595g, filter cake 12g, the main component of the filter ca...

Embodiment 2

[0055] A kind of pretreatment method of the ortho-propoxyphenol production wastewater of the present invention (get the ortho-propoxyphenol production wastewater (600ml for short OP wastewater) of a pesticide factory in Zhuzhou), such as figure 1 shown, including the following steps:

[0056] (1) Acidic flocculation: add 5g of hydrochloric acid to adjust the pH to 6.5, stir at room temperature for 10 minutes, add 9g of wet plant ash, 6g of polysilicate iron copper sulfate composition, make the solution pH 5.5, continue to stir for 0.5 hours, filter, filter cake 32.4g, go to the solid waste incinerator for incineration;

[0057] (2) Neutralization and flocculation: the filtrate filtrate 587g of step (1) gained is poured into a beaker, slowly adds 30% sodium hydroxide 5.38g in 5 minutes, adjusts pH to be 7, adds plant ash 9g and stirs 30 minutes and filters, obtains Colored liquid 581g, filter cake 18g, the main component of the filter cake that this step filters out is plant a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com